In the competitive world of modern printing, efficiency, quality, and sustainability are more crucial than ever. Upgrading to a next-generation LED UV curing system can transform your printing operations, especially in niche markets like label, flexo, and narrow-width printing. This technology isn’t just a trend; it offers a tangible return on investment by enhancing productivity, reducing costs, and opening new market opportunities.

Understanding UV Curing and Its Significance in Print Quality

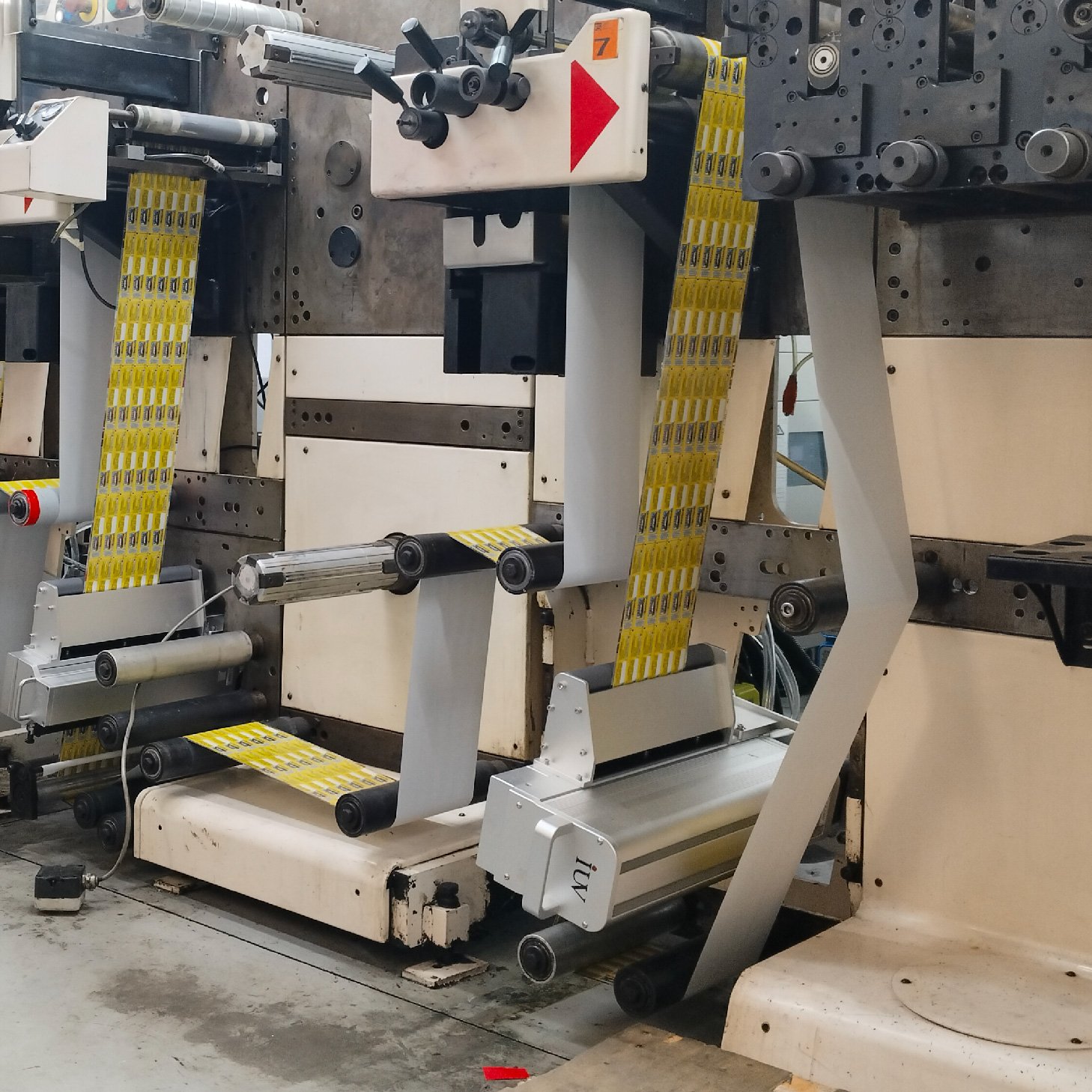

UV curing refers to the process of using ultraviolet light to instantly dry or cure inks, coatings, and adhesives. For label printing, flexography, and other narrow-width applications, UV curing ensures rapid turnaround times and consistent color vibrancy. It improves adhesion on diverse substrates such as plastics, film, or foil, which are common in high-value label and packaging jobs.

Traditional UV systems rely on mercury vapor lamps, which have limitations including high energy consumption, extensive heat emission, and shorter operational life. Next-generation LED UV systems overcome these challenges, leveraging semiconductor technology to deliver focused and energy-efficient UV light.

Advantages of LED UV Curing in Label and Narrow-Width Printing

- Enhanced Productivity and Reduced Downtime

LED UV systems cure inks almost instantaneously, drastically reducing drying times. This allows for faster press speeds and shorter turnaround times. The instantaneous curing capability minimizes downtime between printing and finishing processes, increasing overall throughput.

- Lower Energy Consumption and Operational Costs

Compared to traditional UV lamps, LED UV systems consume significantly less power. They also generate less heat, which means less air conditioning and cooling requirements in the press room. Over time, this translates into substantial savings on energy bills and maintenance.

- Extended Equipment Life and Reduced Maintenance

LED UV lamps have a longer lifespan—often over 20,000 hours—without the need for frequent replacements. This stability minimizes unscheduled downtime and maintenance costs, ensuring smooth and reliable operation.

- Improved Environmental Footprint

By eliminating mercury lamps and reducing energy consumption, LED UV curing contributes to environmentally sustainable practices. For brands focusing on green labeling and eco-conscious production, this upgrade aligns well with sustainability goals.

- Superior Color and Image Quality

Stable and consistent curing results in sharper images, vibrant colors, and increased gloss. This level of quality is pivotal for premium label printing and packaging, where visual appeal commands a premium price.

- Versatility and Substrate Compatibility

LED UV is effective on a wide range of substrates, including sensitive plastics and temperature-sensitive materials. This flexibility expands your capacity to produce diverse label types, from peel-off labels to holographic foils.

ROI Factors for Upgrading to a Next-Generation LED UV System

Making an investment in new curing technology requires careful analysis. The key ROI considerations include:

- Increased Production Capacity: Faster curing speeds and reduced downtime mean higher output at a given time frame.

- Cost Savings: Lower energy bills, reduced maintenance costs, and less waste translate into ongoing savings.

- Expanded Market Reach: The ability to print on innovative substrates enables access to new, higher-margin markets.

- Enhanced Quality: Superior image quality satisfies high-end clients and justifies premium pricing.

- Sustainability Commitments: Eco-friendly practices unlock marketing advantages and comply with industry regulations.

Implementation and Integration Challenges

Transitioning to a Next-Generation LED UV system involves planning and integration. Compatibility with existing press equipment, training staff, and ensuring process adjustments are key steps. Working closely with manufacturer support teams ensures a smooth upgrade and optimizes system performance.

Case Studies and Market Trends

Numerous printing facilities have reported up to a 30% increase in production efficiency after adopting LED UV curing. In label and flexo sectors, clients notice improved registration accuracy and faster job turnaround. Market trends point toward a growing preference for LED UV, driven by environmental mandates and the desire for high-quality output.

Future Outlook: LED UV as a Standard in Niche Printing

As technology advances, the cost of LED UV systems continues to decline while their capabilities expand. Innovations such as multi-wavelength LED UV, automation integration, and real-time curing adjustments promise even greater ROI and flexibility.

In the realms of label printing, flexography, and narrow-width production, LED UV curing isn’t just a choice—it’s a strategic move. By embracing this technology, companies position themselves at the forefront of innovation, sustainability, and profitability. The initial investment is dwarfed by the long-term gains in productivity, quality, and market competitiveness.