The ROI of Investing in a LED UV Curing System for Label Printing

In the competitive world of label printing—whether for flexographic, offset, or narrow-web applications—speed, quality, and sustainability define success. One innovation reshaping this landscape is LED UV curing technology. For printers seeking to future-proof operations, understanding the return on investment (ROI) of upgrading to LED UV systems is critical. Let’s explore how this technology enhances productivity, reduces costs, and aligns with modern environmental demands.

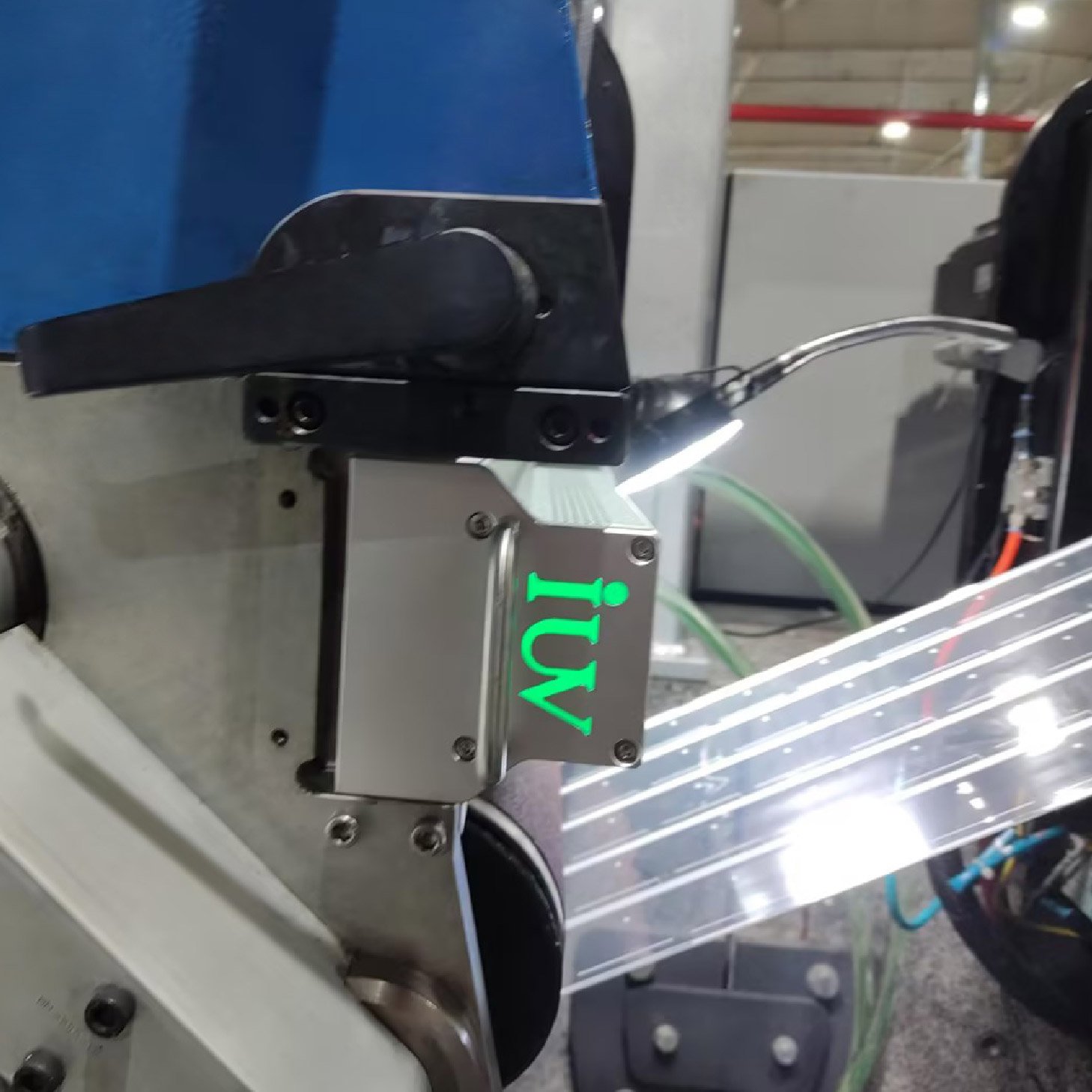

Why LED UV Curing Outperforms Traditional Methods

Traditional mercury arc lamps have long dominated UV curing for labels, but their limitations are glaring. They consume excessive energy, generate heat, require frequent bulb replacements, and contain hazardous materials. LED UV systems eliminate these pain points by:

- Reducing energy consumption by up to 70% (no warm-up time, instant on/off).

- Eliminating heat-sensitive substrate distortion (ideal for thin films and heat-sensitive materials).

- Operating maintenance-free for 20,000 hours (no bulb replacements or mercury disposal costs).

For flexo and narrow-web printers, this translates to faster job turnover, fewer production delays, and lower operational costs.

Precision Curing for Complex Label Designs

Modern labels demand intricate graphics, vibrant colors, and specialty finishes. LED UV curing excels here by enabling precise control over the curing process. Unlike conventional methods, LED systems emit a narrow spectrum of UV light, ensuring consistent ink polymerization without overexposure. This is particularly advantageous for:

- High-density white inks (no yellowing or cracking).

- Cold foil stamping (enhanced adhesion without heat damage).

- Delicate substrates (e.g., synthetic films, shrink sleeves).

Offset printers benefit from sharper dot reproduction, while flexo operators achieve faster drying times for water-based or solvent-free inks. The result? Fewer defects, higher yields, and the ability to tackle premium label projects.

Calculating the ROI: Where Savings Add Up

While the upfront cost of LED UV systems may give pause, the long-term savings are undeniable. Let’s break down the key ROI drivers:

Energy Efficiency

LED UV consumes 50–70% less power than mercury lamps. For a mid-sized label printer running two shifts, this could mean $15,000–$25,000 annual savings on electricity.Reduced Downtime

Mercury lamps require 5–15 minutes to warm up and cool down. LED systems activate instantly, adding 20 productive hours monthly.Lower Maintenance Costs

Eliminating bulb replacements ($500–$1,000 per lamp) and mercury disposal fees ($200–$500 per bulb) saves $5,000–$10,000 yearly.Waste Reduction

Immediate curing minimizes ink spread and substrate warping, cutting material waste by 8–12%.Sustainability Incentives

Many governments offer tax credits for adopting eco-friendly technologies, further improving ROI.

Meeting Eco-Conscious Market Demands

Brands increasingly prioritize sustainability, pushing converters to adopt greener practices. LED UV curing supports this shift by:

- Eliminating ozone emissions (no VOCs or hazardous byproducts).

- Enabling solvent-free inks (safer for food and pharmaceutical labels).

- Reducing carbon footprint (lower energy use longer system lifespan).

Printers leveraging LED UV can market their services as “eco-friendly,” attracting clients in regulated industries like cosmetics, healthcare, and organic foods.

Future-Proofing Your Label Production

The label industry’s shift toward shorter runs, faster turnaround times, and complex designs demands agile technology. LED UV systems not only meet these needs but also adapt to emerging trends:

- Digital hybrid printing (combining inkjet with UV curing for variable data labels).

- Smart packaging (curing conductive inks for RFID/NFC tags).

- Extended gamut printing (vivid colors without drying delays).

By investing now, printers position themselves as innovators capable of handling next-generation projects.

Conclusion: A Strategic Upgrade for Long-Term Growth

For label printers, LED UV curing isn’t just a technical upgrade—it’s a strategic business decision. The combination of energy savings, waste reduction, and enhanced print quality delivers a compelling ROI, often within 12–18 months. As brands demand faster, greener, and more sophisticated labeling solutions, adopting LED UV technology ensures your operation remains competitive and profitable.

Whether you specialize in flexo, offset, or narrow-web printing, the question isn’t if to switch to LED UV, but when. Early adopters gain a first-mover advantage in a market where efficiency and sustainability are no longer optional.