Achieving stunning high-gloss and varnish effects in label printing is a key differentiator. This is where advanced UV curing systems truly shine. These technologies offer unparalleled control and vibrant results, enhancing the visual appeal and tactile experience of printed materials.

In the realm of narrow web printing, particularly for labels and packaging, the demand for premium finishes is ever-increasing. UV curing provides a rapid and efficient method to achieve these effects. Unlike traditional methods that rely on heat or air drying, UV curing uses ultraviolet light to instantly solidify inks and coatings. This process is not only faster but also allows for a wider range of finishes, from deeply glossy to softly matte.

For flexographic printing, UV curing has become a cornerstone technology. Flexo presses, known for their versatility and suitability for a vast array of substrates, benefit immensely from UV inks and lamps. The immediate curing of UV inks prevents smudging and allows for finer detail, crucial for intricate label designs. When paired with UV-activated varnishes, flexo printing can produce eye-catching textures and protective layers that elevate product presentation. This is particularly evident in the food and beverage sector, where labels must be both durable and visually appealing.

Offset printing, or lithography, also leverages UV curing for superior results. In sheetfed and web offset, UV inks and coatings enable printers to achieve exceptional gloss and depth. The ability to print on non-absorbent substrates, such as plastics and foils, is greatly expanded with UV technology. This opens up new possibilities for high-end packaging and specialty labels that require a durable, high-quality finish. The rapid curing also means faster turnaround times and reduced energy consumption compared to conventional drying methods.

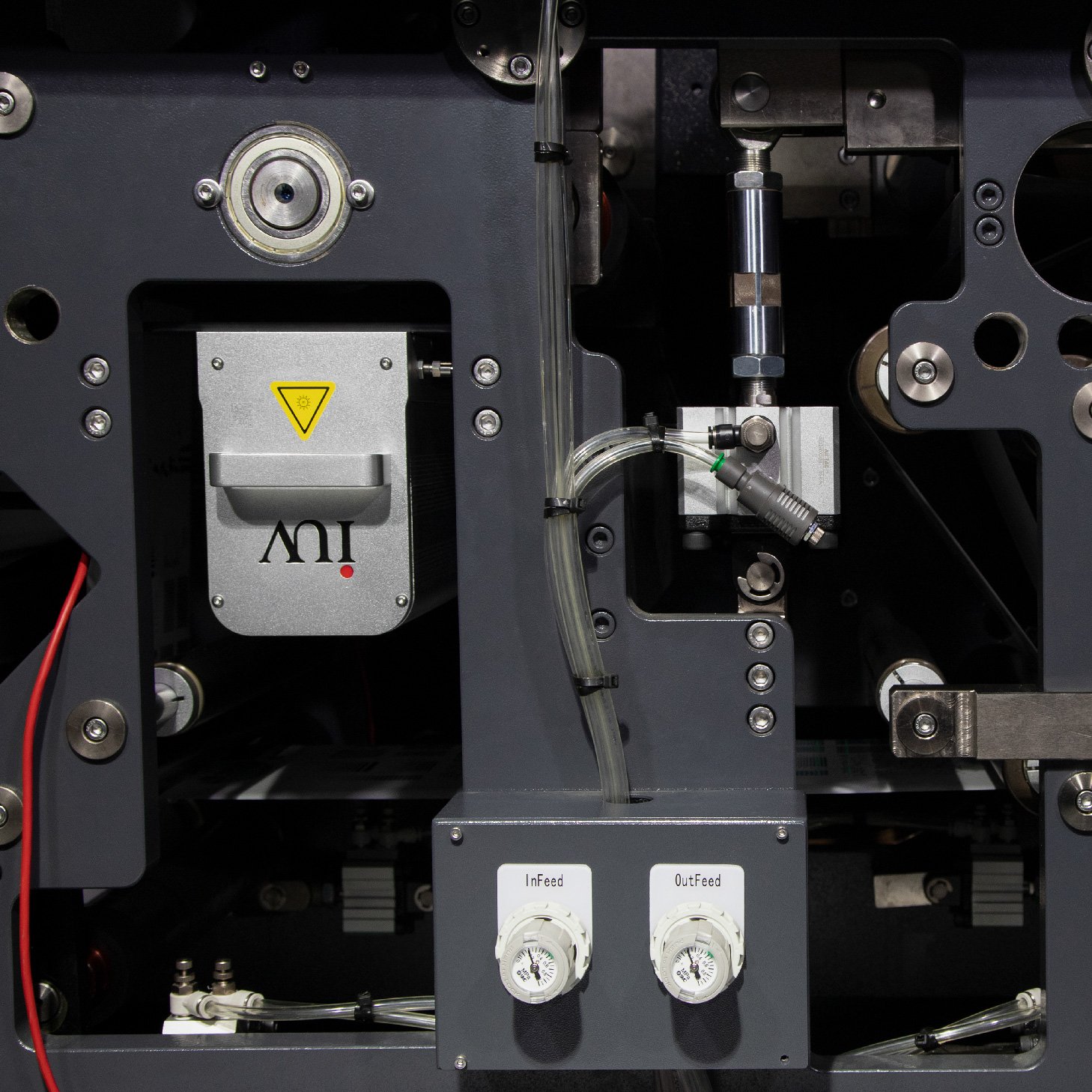

The advent of LED UV curing systems has further revolutionized the industry. Traditional mercury vapor lamps emit significant heat, which can be detrimental to heat-sensitive substrates and increase energy costs. LED UV systems, on the other hand, emit light at specific wavelengths, generate very little heat, and have a much longer lifespan. This translates to lower operational costs, reduced energy consumption, and a safer working environment.

The precision offered by LED UV systems is paramount for achieving consistent high-gloss and varnish effects. The focused light output ensures uniform curing across the printed area, eliminating inconsistencies that can detract from the desired aesthetic. This is especially important when applying thick varnish layers for a tactile, high-build effect, or when creating spot glosses that contrast sharply with matte backgrounds.

In narrow web applications, space is often at a premium. LED UV curing units are compact and easily integrated into existing flexo and offset presses. Their low heat output also means less need for elaborate cooling systems, simplifying the press setup and maintenance. This efficiency is critical for converters who need to maintain high production speeds and adapt quickly to changing job requirements.

The versatility extends to the types of varnishes that can be applied. UV-curable varnishes come in a wide spectrum of formulations, allowing for everything from ultra-high gloss to satin, matte, and even textured finishes. Special effect varnishes, such as pearlescent, metallic, or thermochromic, are also readily available and cure perfectly under UV light. This allows label printers to offer a comprehensive range of finishing options to their clients, enhancing brand appeal and shelf presence.

For printers exploring advanced embellishments, UV curing is indispensable. Techniques like spot UV, where a high-gloss varnish is applied to specific areas of a design, create a dramatic visual contrast. This technique draws attention to logos, key product information, or decorative elements, adding a layer of sophistication. The precision of UV curing ensures that these effects are sharp and well-defined, even on complex graphics.

The environmental benefits of UV curing, especially with LED technology, are also significant. The instant curing process means less volatile organic compounds (VOCs) are released into the atmosphere compared to some conventional inks and coatings. This aligns with growing industry and consumer demand for more sustainable printing practices. Furthermore, the reduced energy consumption of LED UV systems contributes to a smaller carbon footprint.

When considering UV curing for high-gloss and varnish effects, substrate compatibility is key. UV inks and coatings adhere well to a wide range of materials, including paper, film, foil, and various plastics. This broad compatibility makes UV curing a viable solution for a diverse array of label applications, from durable industrial labels to decorative product labels.

The economic advantages are equally compelling. The speed of UV curing dramatically increases production throughput. Faster drying times mean less waiting between processes, allowing for quicker job completion and more efficient use of press time. While the initial investment in UV curing equipment might be higher, the long-term savings in energy, reduced waste, and increased productivity often outweigh the upfront cost.

The ongoing innovation in UV ink and coating formulations continues to expand the possibilities. New chemistries offer enhanced scratch resistance, chemical resistance, and adhesion to challenging substrates. This constant evolution ensures that UV curing remains at the forefront of delivering premium finishes in the competitive label printing market.

For narrow web printers looking to elevate their offerings, mastering UV curing techniques for gloss and varnish effects is a strategic imperative. It’s a technology that delivers both aesthetic excellence and operational efficiency, providing a clear competitive edge in today’s market.