In the evolving landscape of print technology, environmental responsibility is becoming more than a trend—it’s a necessity. UV curing systems, particularly those utilizing LED UV technology, stand out as pioneering solutions that align top-tier print quality with sustainable practices. This shift benefits not only the environment but also enhances operational efficiency and product quality across various printing sectors, including label, flexographic, plate, and narrow-width printing.

The Rise of UV Curing in Modern Printing

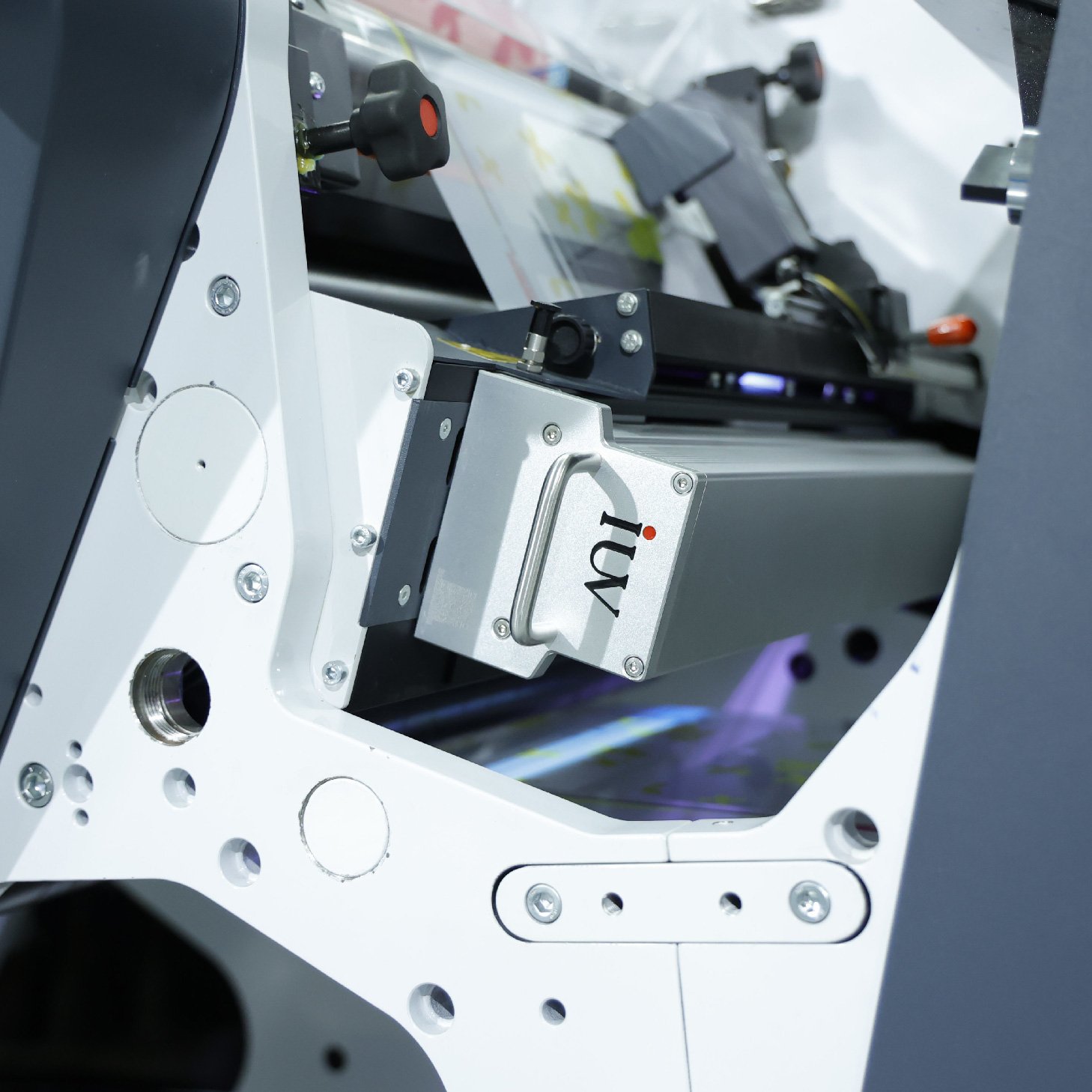

UV curing technology has revolutionized how inks and coatings dry and adhere to substrates. Traditional solvent-based processes often emit volatile organic compounds (VOCs), which pose environmental and health hazards. UV curing, especially LED UV systems, offers a cleaner alternative by using ultraviolet light to instantly dry inks, varnishes, and adhesives. This rapid curing process reduces energy consumption and eliminates the need for solvents, making it an eco-friendly choice across diverse printing applications.

Environmental Advantages of UV Curing Systems

- Reduced VOC Emissions

One of the most significant benefits of UV LED curing is markedly lower VOC emissions. Unlike solvent-based inks, UV inks are nearly VOC-free, leading to a significant decrease in air pollution and health risks for workers. This reduction aligns with stricter environmental regulations and corporate sustainability goals.

- Lower Energy Consumption

LED UV systems consume considerably less energy than traditional mercury vapor lamp systems. Their instant start-up and longer lifespan reduce energy costs and carbon footprint. For narrow-width and label printers, this means more efficient production without sacrificing quality or volume.

- Less Waste and Faster Production

The instantaneous curing process minimizes waste by reducing misprints and rejects. It also accelerates the printing process, enabling rapid turnaround and just-in-time manufacturing. These efficiencies contribute to a more sustainable workflow—saving materials and reducing inventory excess.

- Safer Working Environment

LED UV systems generate minimal heat during operation and don’t produce ozone, unlike older mercury vapor lamps. This creates a safer, more comfortable workspace and less need for special ventilation systems, further reducing environmental impact.

Application-Specific Sustainability Benefits

Different printing processes benefit uniquely from UV curing systems, making their adoption vital for sustainable growth.

Tag and Label Printing

Labels often require durability against moisture, chemicals, and UV exposure. UV curing inks provide these properties without the environmental costs linked to solvent-based inks. The fast curing reduces energy use and enhances productivity, helping brands meet greener standards.

Flexographic (Flexo) Printing

Flexo printing, used widely for packaging and labels, benefits immensely from UV LED systems. They enable high-speed production with precise color registration, minimizing waste and reprints. The clean process supports eco-conscious packaging solutions that appeal to environmentally aware consumers.

Planographic (Plate) Printing

UV technology supports quicker plate processing and lower chemical requirements during platemaking. That translates to less chemical waste and a smaller ecological footprint—important factors as the industry aims for circular sustainability models.

Narrow-Width Printing

Often employed for labels, specialty graphic work, and decorative printing, narrow-width presses excel when equipped with LED UV systems. These systems offer higher precision, reduced energy costs, and reduced VOC emissions, making narrow-format work more sustainable without compromising detail or quality.

Key Features of LED UV Systems for Sustainable Printing

- Instant Curing

LED UV light cures inks and coatings immediately upon exposure, minimizing energy use and speeding up production lines.

- Longer Lifespan and Lower Maintenance

Compared to traditional UV lamps, LED UV sources have a longer operational life—often over 20,000 hours—reducing waste and replacement costs.

- Low Heat Emission

Their cool operation allows printing on heat-sensitive substrates, expanding design flexibility while reducing energy and cooling requirements.

- Environmental Compliance

LED UV systems are compliant with the latest environmental standards, helping businesses meet strict regulatory demands seamlessly.

Driving Sustainability in the Industry

Adopting LED UV curing technology is more than an operational upgrade; it’s a strategic move toward sustainability. It demonstrates a commitment to reducing environmental impact and aligns with global standards for eco-friendly manufacturing practices. Whether it’s printing labels, flexible packaging, or narrow format work, UV curing systems deliver benefits that resonate through the entire supply chain.

As the industry continues to evolve, embracing innovation like LED UV curing positions companies to meet increasing consumer demands for environmentally responsible products. It also ensures compliance with evolving environmental regulations, safeguarding the future of the printing business.

Conclusion

For modern printing operations, sustainability is not optional—it’s integral. UV curing systems, particularly advanced LED variants, offer compelling environmental benefits, including lower emissions, reduced energy costs, and minimized waste. These advantages support a greener future for label, flexo, plate, and narrow-width printing. By integrating these technologies, businesses not only enhance their eco-credentials but also optimize production and product quality, setting a new standard in responsible printing practices.