In the competitive world of high-quality printing, maximizing efficiency while maintaining top-tier output is essential. Downtime during print runs can lead to significant losses in productivity and revenue. To address this challenge, integrating instant-on UV curing systems with LED UV technology into various printing presses, including label, flexo, plate, and narrow-web presses, offers a powerful solution. These advanced systems significantly reduce curing times, streamline workflows, and improve overall operational performance.

The Impact of Downtime in Printing Operations

Every interruption on a printing line disrupts the production schedule, leading to delays and increased costs. Traditional UV curing methods often require lengthy warm-up cycles, which contribute to these delays. In high-demand environments such as label printing and flexography, even a few minutes of waiting can accumulate into hours of lost productivity. Reducing curing time directly correlates with increased throughput, quicker turnaround times, and better resource utilization.

Understanding Instant-On UV Curing Systems

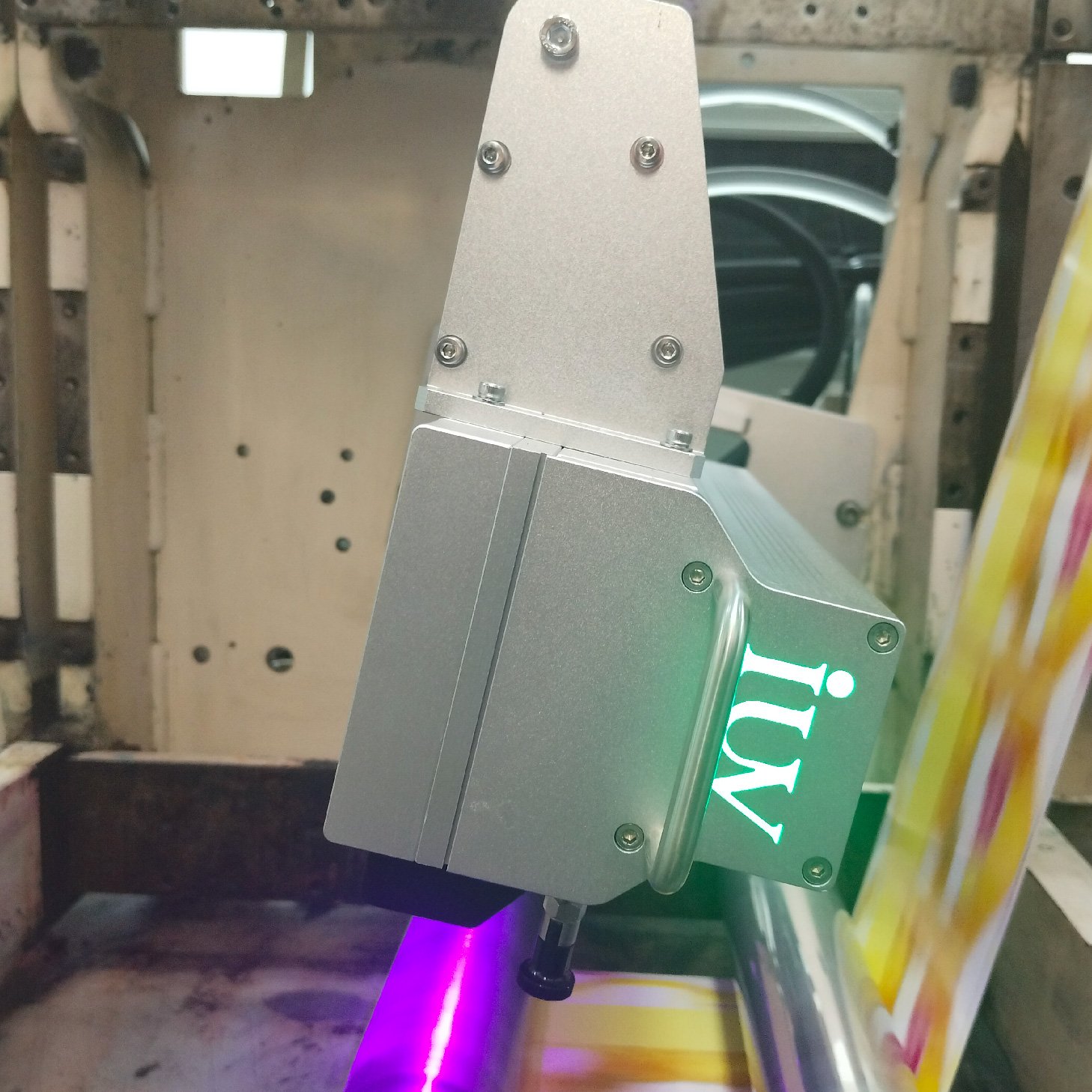

Instant-on UV curing systems are engineered to activate immediately, eliminating the warm-up phase required by conventional UV lamps. This technology is especially advantageous in applications demanding rapid color changes, short runs, or on-demand printing. LED UV curing, a subset of instant-on systems, utilizes light-emitting diodes that emit specific wavelengths designed to cure inks, coatings, and adhesives efficiently.

LED UV curing units are highly durable, consume less energy, and generate minimal heat, enabling safer and more flexible printing environments. Their compact design allows easy integration into existing presses, whether they are used for flexible packaging, label substrates, or narrow-web applications.

Advantages of LED UV in Label and Narrow-Web Printing

Label printing demands precise color reproduction and quick changeovers. LEDs can switch on instantly to cure inks, reducing delays between runs. This capability accelerates production cycles and enhances the ability to meet tight deadlines. Additionally, LED UV systems emit no infrared radiation, minimizing heat transfer to sensitive substrates like films or papers, thus reducing warping and distortion.

In narrow-web printing, space is often limited. The compact nature of LED UV modules means they can fit seamlessly into small press frames, allowing for high-speed curing without bulky equipment. Their energy-efficient operation also lowers operational costs and aligns with sustainable manufacturing practices.

Flexo Printing and UV Curing Optimization

Flexography, a widely used method for packaging and labels, benefits greatly from instant-on UV systems. Customizable cure settings enable operators to adjust intensity quickly, ensuring proper adhesion and ink durability. The rapid curing process minimizes solvent or volatile organic compound (VOC) emissions, contributing to compliance with environmental standards.

LED UV’s precise curing spectrum ensures excellent process control. It offers consistent results even at high speeds, reducing waste associated with under or over-curing. The fast start-up time minimizes downtime during color or design changes, keeping production fluid and responsive to market demands.

Plate and UV Curing Technologies in Commercial Printing

While traditional plate printing often focuses on offset, UV-curable inks are increasingly being used for specialty applications to achieve vibrant, durable images. Instant-on UV systems allow for quick curing of spot or flood coats, improving finish quality and reducing handling time.

Implementing LED UV curing in plate-based processes enhances productivity by enabling immediate curing post-application. This reduces the risk of smudging or damage, especially in high-volume runs. Moreover, the energy efficiency and long lifespan of LED modules translate into lower maintenance costs and higher system availability.

Optimizing Narrow-Web and Specialty Printing

Narrow-web presses, used for labels, decorative coatings, and functional inks, require precise and rapid curing solutions. LED UV’s instant-on capability ensures minimal delays when switching production jobs or changing substrates. The ability to cure inks and coatings instantly reduces the drying time, allowing for inline lamination, embellishments, or finishing processes without delay.

Specialty printing such as security features, holographic effects, or multicolor embellishments benefit from immediate curing, which enhances image fidelity and process speed. LED UV systems can be tailored to specific ink formulations and substrate types, making them versatile for various niche applications.

Enhancing Sustainability and Cost Efficiency

Switching to LED UV curing systems aligns with environmentally sustainable manufacturing practices. Their low energy consumption and absence of hazardous mercury lamps reduce both operational costs and ecological footprint. The reduced heat emission extends the life of sensitive substrates and decreases cooling requirements.

Furthermore, rapid curing minimizes ink and coating waste by ensuring complete adhesion and curing on the first pass. This improved efficiency lowers raw material costs and supports lean manufacturing strategies.

Choosing the Right UV Curing System

When selecting an UV curing system, consider factors such as:

- Compatibility with existing press architecture

- Substrate types and thicknesses

- Ink and coating formulations

- Production speed requirements

- Environmental compliance standards

Partnering with experienced suppliers ensures optimal integration of LED UV systems, maximizing uptime and quality.

Future Trends in UV Curing Technologies

Advancements in LED UV technology continue to push the boundaries of printing efficiency. Innovations such as customizable LED arrays, digital control interfaces, and integrated sensors allow for smarter, more adaptable curing solutions. As markets demand faster turnaround times and higher quality, instant-on UV systems will become standard in a wide range of printing environments.

The shift toward sustainable, energy-efficient printing processes makes LED UV curing an investment with long-term benefits. Manufacturers who adopt these systems early will be positioned to meet evolving customer expectations and regulatory standards effectively.

In summary, integrating instant-on UV curing systems, particularly those utilizing LED technology, transforms printing operations. They offer rapid startup times, reduced downtime, cost savings, and environmental advantages—all crucial for thriving in today’s competitive print landscape. Whether for labels, flexography, plates, or narrow-web applications, these systems enable printers to deliver top-quality products efficiently and sustainably.