LED UV Curing System vs. Mercury UV System: Key Differences

When it comes to UV curing technology, two primary systems dominate the market: LED UV curing systems and traditional mercury UV systems. Each technology has its own characteristics, advantages, and ideal applications. Understanding the differences between these two systems can help you make informed decisions for your specific needs.

Heat Dissipation

Mercury UV Systems

-

High Heat Emission: Mercury vapor lamps generate significant heat during operation, with a large portion of energy converted into heat rather than UV light.

-

Temperature Management: The arc tube operates at extremely high temperatures, often exceeding 100°C (212°F), requiring complex cooling systems.

LED UV Systems

-

Low Heat Emission: LED UV systems operate at much lower temperatures, with most energy used for UV emission rather than heat.

-

Temperature Range: Typically operates between 40°C and 80°C (104°F to 176°F), making them suitable for heat-sensitive materials.

Impact on Materials

Mercury UV Systems

-

Material Deformation: High temperatures can cause warping, shrinking, or deformation of heat-sensitive materials.

-

Discoloration: Prolonged heat exposure can lead to color degradation or yellowing.

-

Adhesion Problems: Micro-cracks or inconsistent adhesion may occur with thin or delicate substrates.

LED UV Systems

-

Minimal Thermal Impact: Ideal for sensitive substrates like plastics, films, paper, and electronics components.

-

Reduced Warping and Shrinkage: Maintains material integrity during curing.

-

Improved Material Compatibility: Suitable for a wider variety of materials, including heat-sensitive ones.

Energy Efficiency

Mercury UV Systems

-

Higher Energy Consumption: Requires significantly more energy to operate, with additional power needed for cooling systems.

-

Energy Waste: A substantial portion of energy is wasted as heat rather than used for curing.

LED UV Systems

-

Lower Energy Use: Typically consumes 50-70% less energy than traditional UV lamps.

-

Reduced Cooling Needs: Minimal heat production reduces overall energy consumption for temperature control.

Environmental Impact

Mercury UV Systems

-

Material Deformation: High temperatures can cause warping, shrinking, or deformation of heat-sensitive materials.

-

Discoloration: Prolonged heat exposure can lead to color degradation or yellowing.

-

Adhesion Problems: Micro-cracks or inconsistent adhesion may occur with thin or delicate substrates.

LED UV Systems

-

Minimal Thermal Impact: Ideal for sensitive substrates like plastics, films, paper, and electronics components.

-

Reduced Warping and Shrinkage: Maintains material integrity during curing.

-

Improved Material Compatibility: Suitable for a wider variety of materials, including heat-sensitive ones.

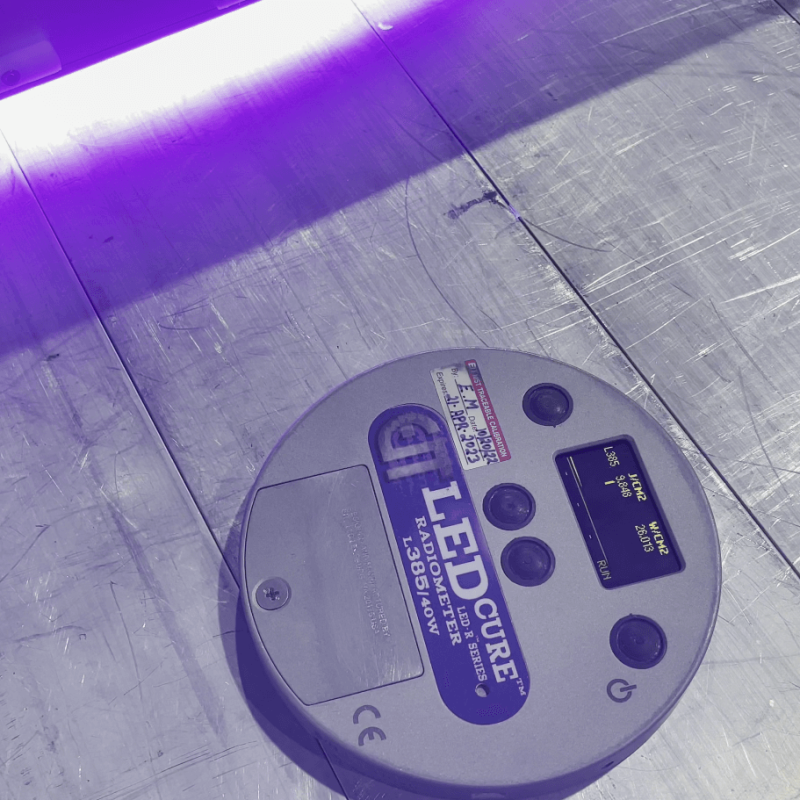

Curing Efficiency and Speed

Mercury UV Systems

-

Curing Efficiency: Affected by various factors including lamp power, ink type, and curing distance.

-

Warm-Up Period: Requires a warm-up period to reach optimal working conditions, resulting in slower curing speeds.

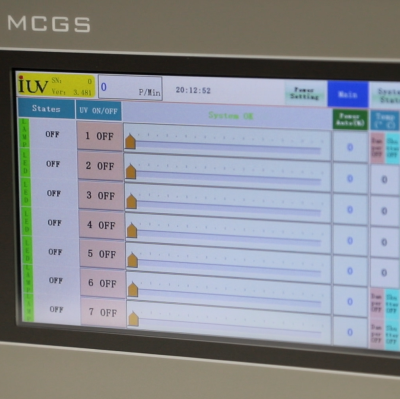

LED UV Systems

-

Higher Curing Efficiency: Concentrated energy and instant-on capability allow for faster curing.

-

Faster Curing Speed: Suitable for high-speed production lines and applications requiring quick curing.

Lifespan and Maintenance

Mercury UV Systems

-

Shorter Lifespan: Typically lasts several hundred to a few thousand hours.

-

Frequent Maintenance: Regular lamp replacements and cooling system maintenance increase costs and downtime.

LED UV Systems

-

Longer Lifespan: Generally exceeds tens of thousands of hours.

-

Lower Maintenance Costs: Less prone to damage and requires fewer replacements.

Cost Considerations

Mercury UV Systems

-

Lower Initial Cost: Relatively affordable upfront investment.

-

Higher Long-Term Costs: Short lamp lifespan, high energy consumption, and frequent maintenance increase long-term expenses.

LED UV Systems

-

Higher Initial Cost: May have a higher upfront price.

-

Lower Long-Term Costs: Long lifespan, low energy consumption, and reduced maintenance needs result in significant savings over time.

Conclusion

The choice between LED UV curing systems and mercury UV systems depends on your specific application requirements, material sensitivity, energy efficiency needs, and long-term cost considerations. LED UV systems offer significant advantages in heat management, energy efficiency, environmental impact, and curing precision, making them an increasingly preferred choice for modern industrial applications.

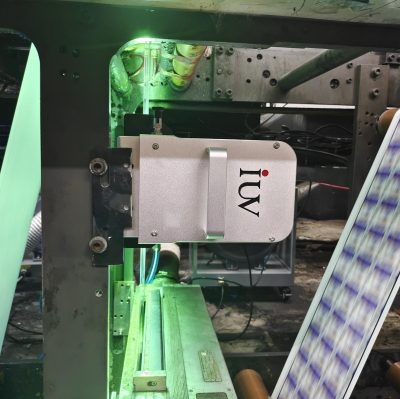

Contact IUV LED UV Experts