In the fast-paced world of label printing, maximizing efficiency while maintaining high quality is essential. UV curing systems have revolutionized this industry, especially with the advancements in LED UV technology. This article explores how UV curing systems enhance productivity in label, flexo, and letterpress printing, focusing on LED UV innovation.

The Role of UV Curing in Label Printing

Label printing demands precision, quick turnaround times, and vibrant colors. UV curing systems accelerate drying and curing processes, leading to faster production cycles. These systems enable immediate handling of printed labels, reducing bottlenecks common in traditional solvent or aqueous-based inks.

Advantages of UV Curing Systems

Traditional drying methods rely on heat or solvents, often resulting in longer drying times and increased operational costs. UV curing eliminates these issues by using ultraviolet light to instantaneously polymerize inks and coatings. This results in immediate finished products that are ready for downstream processes or shipment.

The primary benefits include:

- Rapid Turnaround: Immediate curing shortens the print-to-finish cycle.

- Vibrant Color Retention: UV inks maintain color brightness and sharpness.

- Surface Quality: Produces smooth, gloss, or matte finishes, enhancing label appearance.

- Environmental Benefits: Reduces solvent emissions and VOCs, creating a safer work environment.

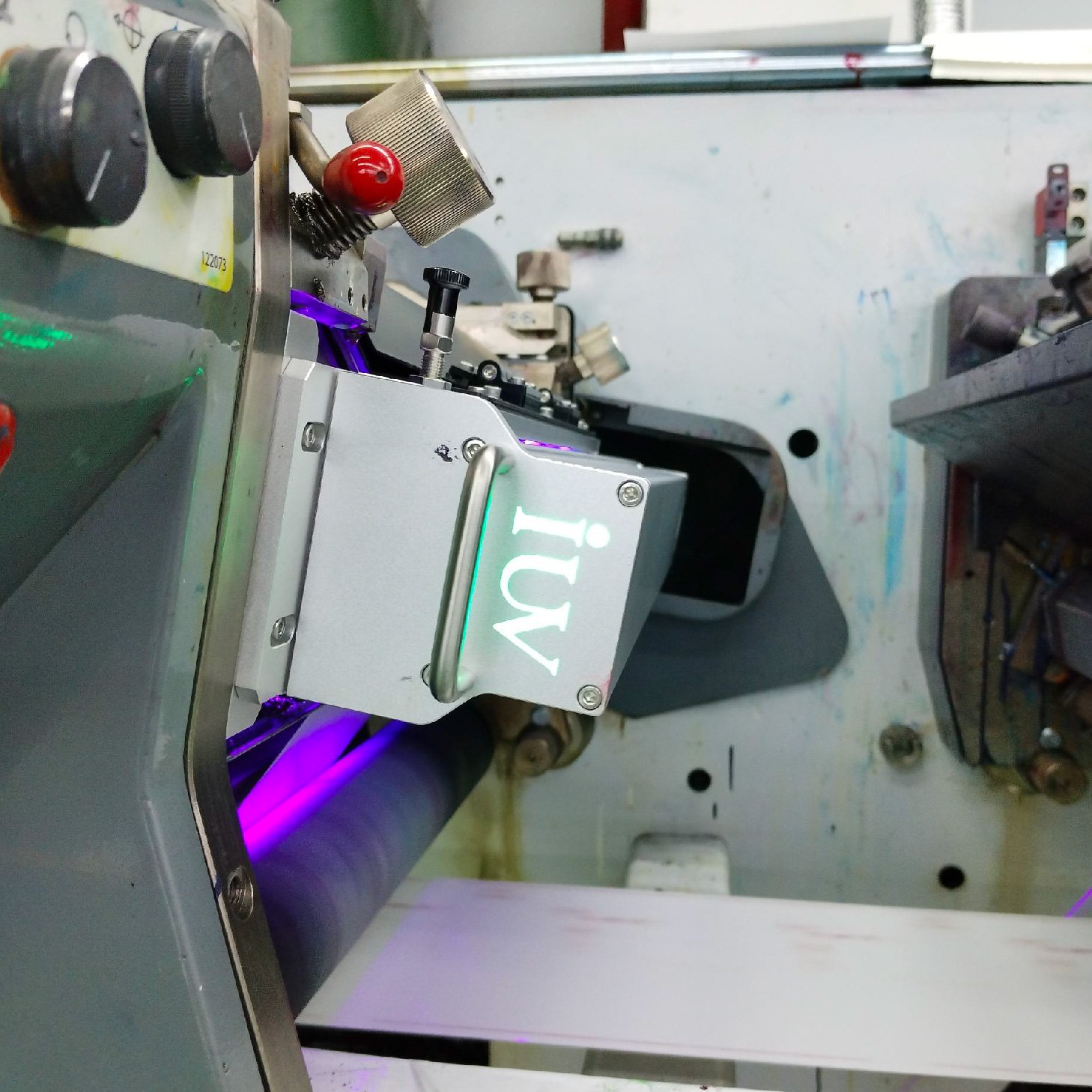

LED UV Technology in Label Printing

LED UV curing systems represent a leap forward in curing technology. Unlike traditional mercury vapor lamps, LED UV sources are energy-efficient, generate less heat, and have a longer lifespan.

Why LED UV is transformative:

- Lower Energy Consumption: Reduced power needs translate to lower operating costs and a smaller carbon footprint.

- Minimal Heat Damage: The cooler curing process preserves substrate integrity, especially for heat-sensitive materials like films and specialty papers.

- Instant On/Off: LED lights turn on immediately, streamlining job changes and reducing waste.

- Extended Equipment Life: Longer-lasting LEDs decrease maintenance intervals and total ownership costs.

Enhancing Flexo and Letterpress Printing

Narrow-web flexo and letterpress printing benefit significantly from UV curing. These processes often involve intricate designs and fine line work that require sharp, crisp images. UV curing helps lock in detail with high adhesion levels, preventing smudging or offsetting.

Moreover, UV systems facilitate the use of thicker inks and elaborate coatings, enriching textural effects and product appeal. This capability broadens design options, enabling brands to stand out on crowded shelves.

UV Curing for Foil and Special Effects

Most label designs incorporate metallic foils, holographics, or textured finishes. UV curing enables secure curing of adhesives used in foil application and special coatings, ensuring durability and enhanced visual appeal. This integration creates labels that are both eye-catching and resilient against wear.

Increased Productivity with Narrower Ink Paths

Narrower print widths demand precise, fast curing to keep pace. LED UV systems excel here, offering quick start-up times and consistent curing across the entire substrate. These attributes support high-speed presses and complex multi-layer jobs, reducing downtime and increasing throughput.

Environmental and Cost Benefits

Switching to UV LED systems can significantly cut operational costs:

- Energy savings due to lower power consumption.

- Reduced waste thanks to minimal curing variability.

- Lower maintenance because LEDs have fewer components that require replacement.

- Compliance with environmental regulations, due to reduced VOC emissions.

Improving Sustainability in Label Production

Modern consumers increasingly favor eco-friendly products. UV LED systems align with sustainability goals by reducing hazardous waste and minimizing energy use. Brands adopting these technologies enhance their reputation and appeal to environmentally conscious markets.

Future Trends and Innovations

As UV LED technology progresses, expect further innovations like:

- Higher curing intensities for improved adhesion on challenging substrates.

- Hybrid systems combining UV LED with other light sources for versatile curing.

- Integration with digital printing to enable on-demand, customized labels with rapid turnaround.

Final Thoughts

The incorporation of UV curing systems, especially LED UV technology, transforms label printing. Faster production times, superior quality, and environmental benefits make it a strategic investment. As the industry evolves, adopting advanced curing solutions will be essential for manufacturers aiming for efficiency, innovation, and sustainability.

Decisions in printing technology should always consider specific operational needs and long-term goals. Embracing LED UV curing not only boosts productivity but also positions brands for future growth in a competitive marketplace.