How UV Curing Systems Revolutionize Printing on Heat-Sensitive Materials

The printing industry faces unique challenges when working with heat-sensitive substrates like thin films, adhesives, plastics, and specialty papers. Traditional drying methods often damage these materials, causing warping, discoloration, or reduced adhesive performance. UV curing systems—particularly LED-based technologies—have emerged as game-changers, enabling precise, energy-efficient curing without thermal stress. Let’s explore how this innovation transforms label, flexographic, offset, and narrow-web printing processes.

UV Curing 101: Instant Polymerization Without Heat

UV curing systems use ultraviolet light to trigger a photochemical reaction in specially formulated inks, coatings, and adhesives. Unlike conventional heat-based drying, which relies on evaporation, UV energy instantly converts liquid materials into solid polymers through cross-linking. This process occurs at ambient temperatures, eliminating heat-related substrate damage. Key components include:

- Photoinitiators: Chemicals that absorb UV energy to start polymerization.

- LED UV Lamps: Mercury-free light sources emitting specific wavelengths (365-405 nm).

- Low-IR Emissions: Reduced radiant heat compared to traditional UV arc lamps.

Label Printing: Precision on Delicate Films

Pressure-sensitive labels often use thin PET, PE, or PVC films that deform under heat. UV curing enables:

- Faster line speeds: Instant curing allows immediate die-cutting or lamination.

- Vibrant opaque whites: High-density pigments cure evenly without substrate shrinkage.

- Cold foil bonding: Adhesives cure at low temps, preserving metallic foil brilliance.

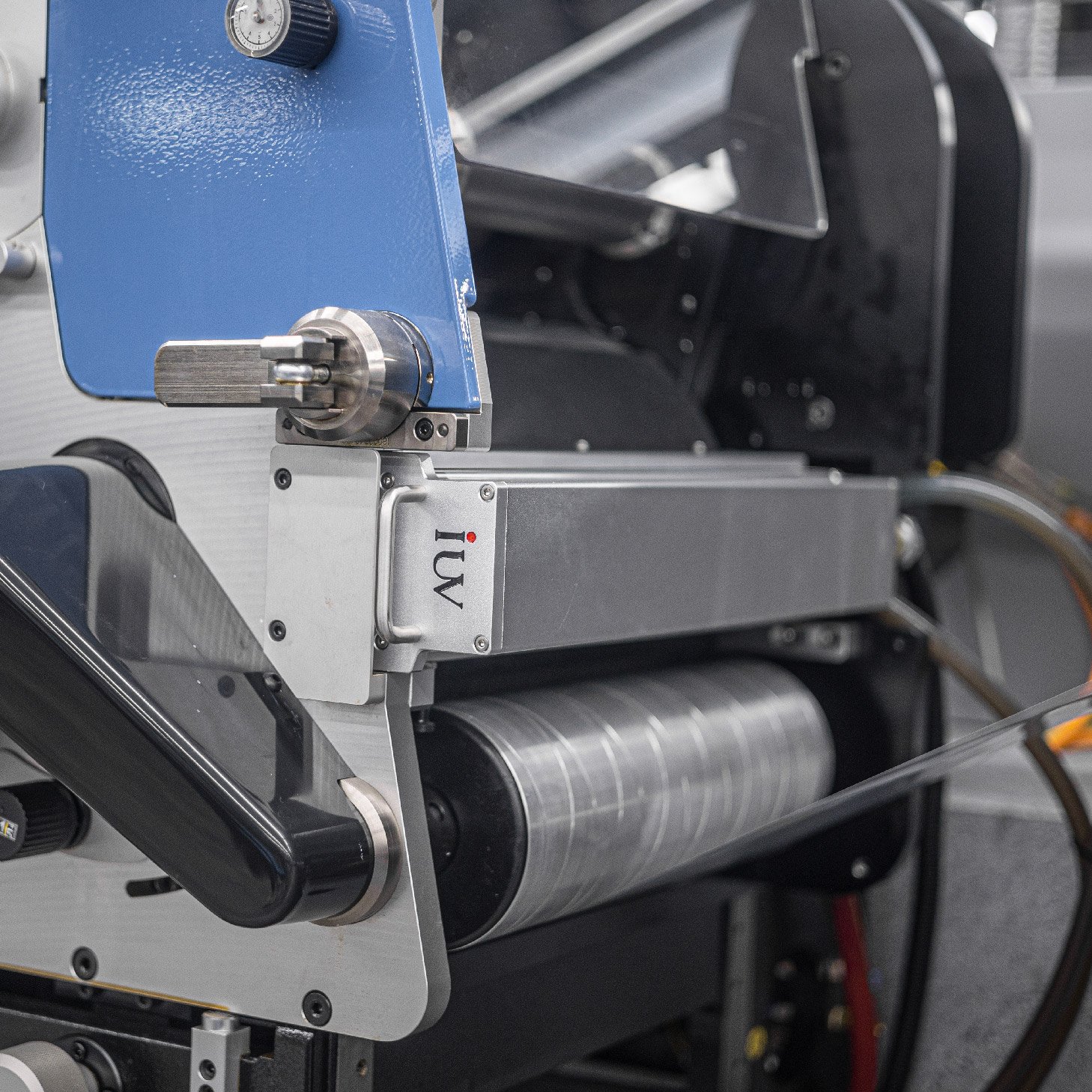

LED UV systems are ideal for label presses, as their compact design fits narrow-web setups while reducing energy use by 70% versus mercury lamps.

Flexographic Printing: Expanding Substrate Options

Flexo printers traditionally avoided heat-sensitive materials due to prolonged drying times. UV curing eliminates this limitation:

- Expanded material range: Print on shrink sleeves, thermal transfer ribbons, or biodegradable films.

- Reduced waste: Immediate curing minimizes smudging for quick job changeovers.

- Enhanced durability: UV-cured flexo inks resist abrasion and chemicals better than solvent-based alternatives.

Hybrid systems combining UV and EB (electron beam) curing further optimize results for food packaging or medical applications requiring ultra-low migration.

Offset Printing: Tackling Plastic Cards and Foils

Sheetfed offset printers leverage UV curing to handle synthetic papers, acrylics, and metallic stocks:

- No spray powder needed: Cured sheets are stackable immediately.

- Sharper dot reproduction: Instant ink fixation prevents dot gain on non-porous stocks.

- Dual-purpose coatings: Apply glossy or textured effects without secondary processes.

LED-UV offset presses achieve 95% cure rates at speeds exceeding 15,000 sheets/hour, making them viable for short-run PVC cards or promotional items.

Narrow-Web Printing: Efficiency for Specialty Applications

Narrow-web converters benefit from UV curing’s adaptability:

- Multi-layer printing: Cure each ink layer instantly for complex security patterns.

- Low-Odor production: UV formulations emit minimal VOCs, ideal for medical or cosmetic packaging.

- Energy savings: LED systems consume 50% less power than conventional drying tunnels.

A 2023 study showed narrow-web UV presses reducing setup times by 40% when switching between heat-sensitive substrates like BOPP and heat-transfer vinyl.

Why LED UV Outperforms Traditional Systems

- Heat Management: LED arrays emit minimal infrared radiation, keeping substrate temps below 40°C.

- Longevity: 20,000 hour lamp life vs. 1,000–2,000 hours for mercury bulbs.

- Eco-Compliance: No ozone generation or hazardous mercury disposal.

Future Trends: UV Curing and Sustainable Materials

As brands adopt compostable films and paper-based alternatives, UV curing supports greener printing:

- Compatibility with water-based UV inks (reducing monomer content).

- Enabling low-energy production of recyclable packaging.

- Facilitating print-on-demand models to cut overproduction.

Conclusion

UV curing systems redefine possibilities for heat-sensitive material printing by merging speed, quality, and substrate versatility. From durable labels on polyethylene to intricate designs on thermal films, this technology empowers printers to meet evolving market demands while boosting sustainability. As LED UV systems become more accessible, their role in advancing flexible packaging, smart labels, and eco-conscious printing will only grow—positioning early adopters for long-term competitive advantage.