How Smart UV Curing Systems Are Transforming the Printing Industry

In today’s competitive printing landscape, technology advancements continue to reshape how brands communicate visually. Among these innovations, Smart UV curing systems stand out for their efficiency, quality, and environmental benefits. Particularly in niche sectors like label printing, flexography, plate printing, and narrow-width printing, UV curing technology is revolutionizing operational workflows and final product quality.

The Rise of UV Curing Technology in Modern Printing

UV curing involves using ultraviolet light to instantly dry or cure inks, coatings, and adhesives. Traditional curing methods often relied on solvent evaporation, which was time-consuming and generated volatile organic compounds (VOCs). UV systems, especially those integrated with smart controls, eliminate these issues by applying energy directly where needed, drastically reducing production time and environmental impact.

Smart UV curing systems leverage LED UV light sources, offering precise control over curing intensity and timing. This high level of customization improves the adhesion, durability, and appearance of printed materials across various substrates. As a result, printers experience faster throughput and higher-quality outputs, making UV curing an essential component of high-end and industrial printing.

Label Printing: Precision and Speed Enhanced

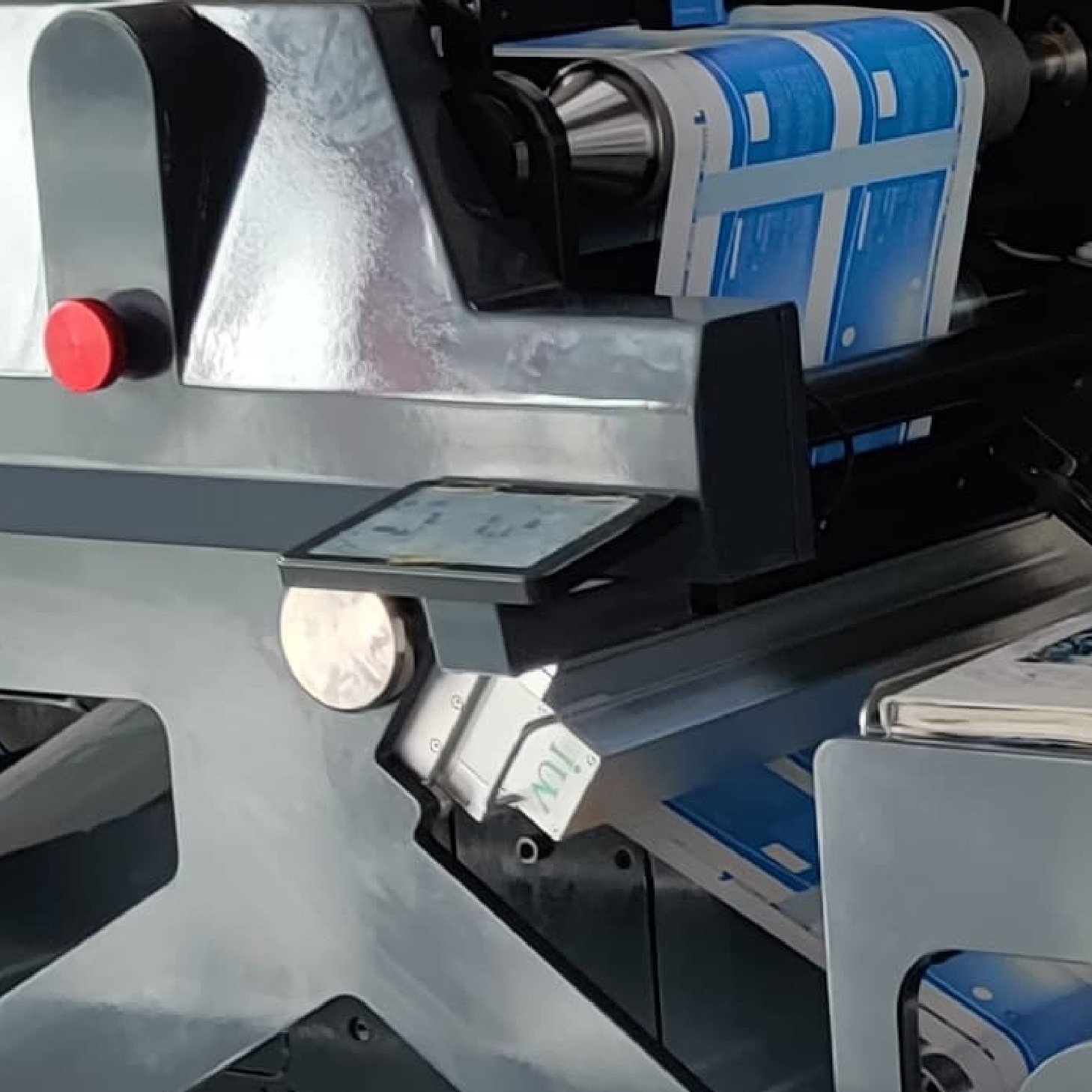

Label printing demands high accuracy, vibrant colors, and quick turnaround times. Smart UV LED curing systems excel here by rapidly curing inks on diverse label substrates, including plastics, foils, and papers. The instant curing minimizes smudges and tackiness, enabling high-speed production lines with minimal waste.

Furthermore, UV curing’s ability to cure on non-porous surfaces ensures labels adhere firmly without cracking or peeling. The adaptability of LED UV sources allows for fine control over curing density, ensuring consistent quality on complex label designs with intricate details or special finishes. This translates into shorter lead times, lower operational costs, and the ability to fulfill just-in-time orders effectively.

Flexography and Plate Printing: Elevating Quality Standards

Flexographic printing, a key method for packaging and label production, benefits significantly from smart UV systems. The quick curing process maintains high line speeds, which is vital for large-volume runs. Additionally, the precision of LED UV curing helps prevent ink bleed, enabling sharper images and finer details.

When it comes to plate printing, especially with the trend toward digital plate production and high-resolution outputs, UV curing enhances the durability of printing plates and improves color vibrancy. The consistent energy output of smart UV systems reduces the risk of uneven curing, extending the lifespan of printing plates and improving overall print consistency.

Narrow-Width Printing: Achieving Pinpoint Accuracy

Narrow-width printing, often used for specialty items like security tags, scratch-off labels, and advertising strips, requires meticulous control over ink spread and curing. Smart UV systems provide the ability to precisely focus UV light on localized sections of the substrate, ensuring crisp images and sharp edges.

LED UV’s low heat emission protects heat-sensitive substrates, preventing warping or distortion. This capability is especially important in niche applications where material integrity can be compromised by excessive heat. The rapid curing also facilitates inline finishing processes, allowing for seamless production workflows.

Advantages of LED UV Curing Systems

The shift to LED UV curing technology offers numerous advantages over traditional mercury vapor lamps. LEDs provide instant start-up, no warm-up phase, and consistent output over their lifespan—reducing downtime and maintenance costs. Their energy efficiency lowers power consumption and operational expenses, contributing to greener print shops.

Smart controls integrated into LED UV systems enable real-time monitoring and adjustment of curing parameters, ensuring optimal curing results every time. This automation not only guarantees quality but also boosts productivity by reducing setup times and rework.

Environmental Benefits and Sustainability

With increasing environmental awareness, UV LED systems stand out for being eco-friendly options. They emit no VOCs, reducing hazardous emissions associated with solvent-based curing. The low heat output means less energy is wasted, and there’s less need for extensive cooling systems.

Additionally, the long lifespan of LED UV lighting reduces waste and replacement frequency. Many printers now see UV LED curing as the foundation of sustainable printing operations, aligning with global efforts to minimize environmental footprints without compromising on quality.

Future Trends in UV Curing for Printing

Looking ahead, advancements in smart UV technology are expected to focus on finer control, expanded spectral ranges, and integration with digital workflows. The development of multi-wavelength LED sources will open possibilities for curing specialized inks and coatings, broadening application scopes.

Furthermore, the integration of artificial intelligence and IoT connectivity will enable predictive maintenance and automatic calibration, boosting efficiency further. As sustainability remains a central concern, innovations will continue to focus on reducing energy consumption and toxic emissions, cementing UV LED curing’s role in forward-thinking printing enterprises.

Final Thoughts

The transformation brought by smart UV curing systems is undeniable. In diverse printing segments such as label, flexographic, plate, and narrow-width printing, these systems deliver unmatched speed, precision, and environmental sustainability. Companies investing in LED UV technology position themselves at the forefront of innovation, satisfying demanding quality standards while enhancing operational efficiency.

Embracing these advancements means not only keeping pace with industry changes but also unlocking new creative and commercial possibilities. As UV curing technology continues to evolve, it will further empower printers to produce higher quality outputs faster and greener than ever before.