Discover how IUV’s UV LED curing systems reduce print turnaround times. Learn about the benefits of instant curing, increased production speeds, and reduced downtime in our comprehensive guide.

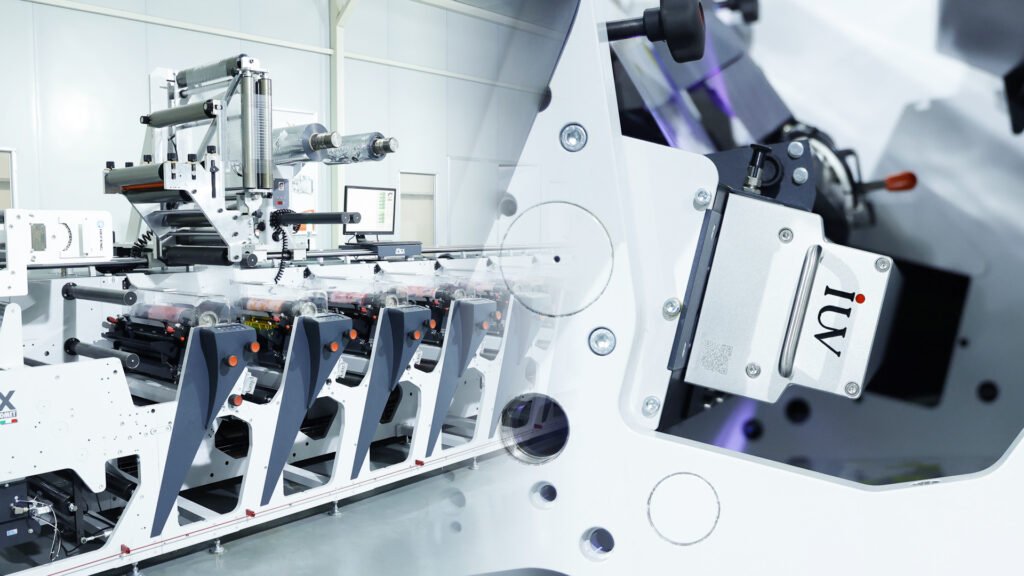

Introduction: Revolutionizing Print Turnaround with IUV’s UV LED Technology

- In the competitive printing industry, reducing turnaround times is crucial for meeting customer demands and maintaining a competitive edge.

- IUV’s UV LED curing systems provide advanced solutions that significantly enhance print turnaround times, allowing for faster production cycles without compromising quality.

- This guide explores how IUV’s UV LED technology impacts print turnaround times and boosts overall efficiency in printing operations.

Understanding UV LED Curing Technology

- What is UV LED Curing?

- UV LED curing involves using light-emitting diodes (LEDs) to emit ultraviolet (UV) light, which instantly cures inks and coatings.

- This process is faster and more efficient than traditional curing methods, making it ideal for high-speed printing applications.

- Benefits of UV LED Curing:

- Instantaneous curing

- Energy efficiency

- Long-lasting LEDs

- Low maintenance requirements

Key Impact Areas on Print Turnaround Times

- 1. Instantaneous Curing for Faster Production

Immediate Curing:

- IUV’s UV LED curing systems provide immediate curing upon exposure to UV light, eliminating the need for extended drying times and allowing for faster production cycles.

Streamlined Workflow:

- The rapid curing process eliminates bottlenecks in the production line, ensuring a smooth and efficient workflow from start to finish.

- 2. Increased Production Speeds

High Throughput:

- The ability to cure inks and coatings instantly allows printers to handle more jobs in less time, significantly increasing throughput and enabling high-volume production.

Consistent Quality:

- UV LED curing ensures consistent print quality across all jobs, reducing the need for reprints and further enhancing production speed.

- 3. Reduced Downtime and Maintenance

Long-Lasting LEDs:

- The LEDs in IUV’s curing systems have a significantly longer lifespan compared to traditional mercury vapor lamps, reducing the frequency of lamp replacements and minimizing downtime.

Low Maintenance Requirements:

- The robust design of UV LED curing systems means less time spent on maintenance, allowing operators to focus on productive tasks and maintain continuous production.

- 4. Energy Efficiency and Cost Savings

Reduced Energy Consumption:

- IUV’s UV LED curing systems consume significantly less energy than traditional curing methods, leading to lower operational costs and contributing to overall workflow efficiency.

Instant On/Off Capability:

- The instant on/off capability of UV LED systems eliminates warm-up and cool-down periods, further enhancing energy efficiency and reducing idle times.

- 5. Versatile Applications

Wide Substrate Compatibility:

- IUV’s UV LED curing systems are compatible with a variety of substrates, including paper, plastic, and metal. This versatility allows printers to handle diverse printing jobs efficiently and meet varying customer needs.

Adjustable Curing Settings:

- Operators can precisely control curing parameters to optimize the curing process for different materials and inks. This flexibility ensures high-quality results across a wide range of applications.

Achieving Faster Print Turnaround with IUV’s UV LED Technology

IUV’s UV LED curing systems are a game-changer for printing companies looking to reduce print turnaround times and increase production efficiency.

- From instant curing and accelerated production speeds to energy efficiency and minimal maintenance, these advanced systems provide the tools necessary to optimize printing operations and achieve superior results.

- By adopting IUV’s UV LED technology, printers can streamline their workflows, reduce operational costs, and deliver exceptional prints with unprecedented speed and efficiency.