How UV Curing Systems Enhance Adhesion Across Diverse Printing Substrates

In the fast-paced world of commercial printing, achieving consistent adhesion on substrates like plastics, metals, and specialty papers remains a critical challenge. UV curing systems, particularly those using advanced LED technology, have revolutionized how printers tackle adhesion issues while boosting efficiency. Let’s explore how this technology optimizes results in label, flexographic, offset, and narrow-web printing.

Why Adhesion Matters in Printing

Adhesion determines whether inks, coatings, or adhesives bond permanently to a substrate. Poor adhesion leads to peeling, cracking, or fading—deal-breakers for product labels, packaging, or industrial prints. Traditional drying methods often struggle with non-porous materials or temperature-sensitive substrates. UV curing eliminates these limitations by using light energy instead of heat to create durable molecular bonds.

The Science Behind UV Curing and Adhesion

UV curing systems expose photoinitiators in inks or coatings to specific wavelengths, triggering an instant polymerization process. This creates a cross-linked network that locks pigments and resins into the substrate’s surface. Unlike solvent-based systems, UV-cured materials don’t rely on evaporation, ensuring minimal shrinkage and maximizing surface contact for stronger adhesion.

LED UV technology further refines this process by:

- Emitting precise wavelengths (365-405 nm) for optimal photoinitiator activation

- Operating at lower temperatures to prevent substrate warping

- Consuming 70% less energy than mercury-vapor lamps

Substrate-Specific Solutions in Key Printing Sectors

1. Label Printing: Conquering Plastic and Metallic Surfaces

Pressure-sensitive labels demand flawless adhesion on PET, polypropylene, and metallic films. UV curing excels here by:

- Penetrating glossy or textured surfaces without heat distortion

- Enabling instant curing of adhesives for high-speed converting

- Supporting scratch-resistant coatings for durable barcodes and graphics

2. Flexographic Printing: Versatility for Packaging

From corrugated cardboard to shrink sleeves, flexo printers rely on UV systems to:

- Cure thick ink layers on porous substrates without absorption issues

- Maintain color consistency across recycled and virgin materials

- Reduce dot gain for sharper graphics on flexible packaging

3. Offset Printing: Precision on Specialty Stocks

UV-enabled offset presses deliver:

- Smudge-free curing of dense inks on synthetic papers and foils

- Enhanced metallic/fluorescent ink adhesion for premium finishes

- Immediate post-curing die-cutting compatibility

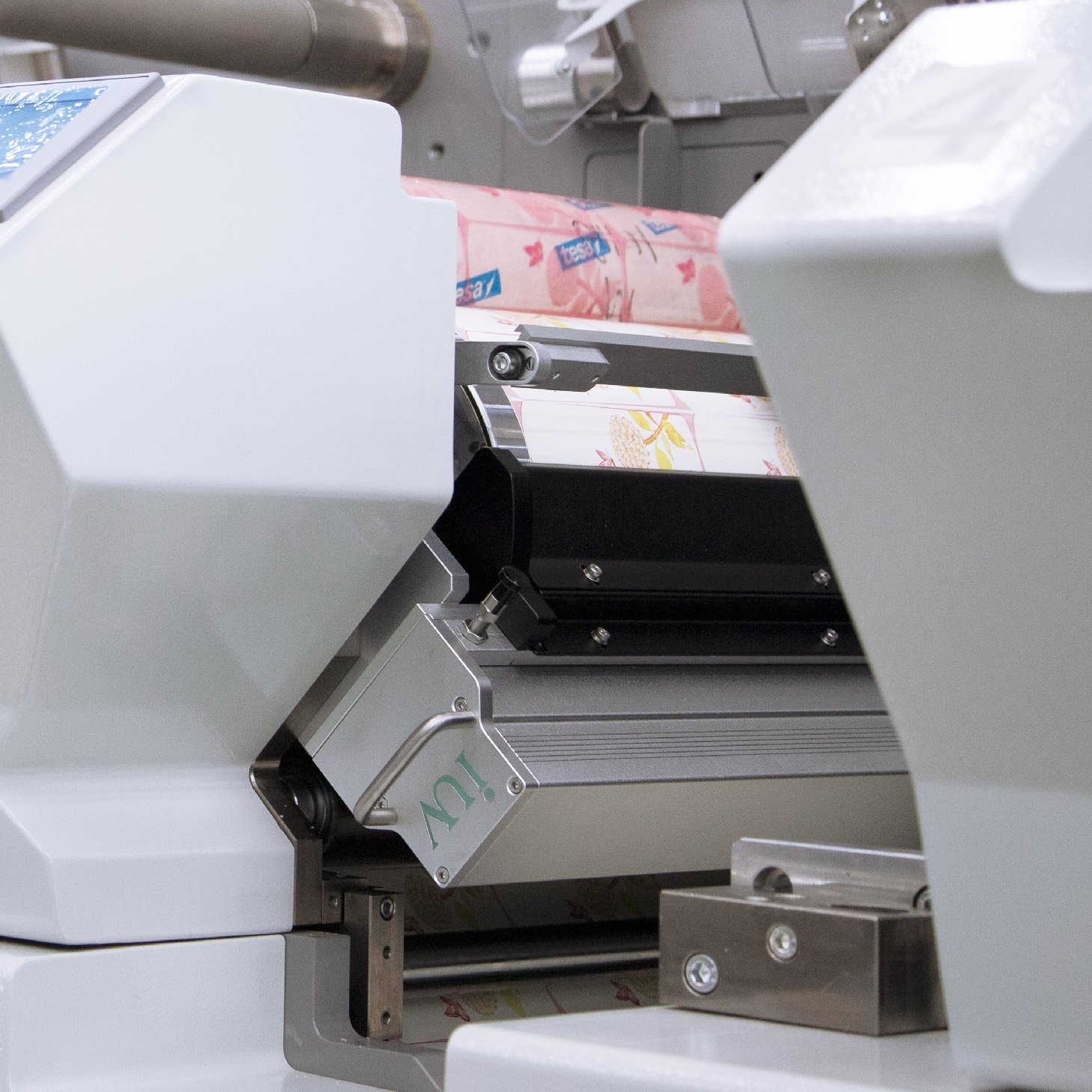

4. Narrow-Web Printing: Speed Meets Complexity

In tags, tickets, and security printing, LED UV systems:

- Cure intricate security inks and overlays without migration

- Handle hybrid substrates (e.g., paper/plastic composites)

- Support sequential curing for multilayer tactile effects

Optimizing UV Curing for Challenging Materials

Low-Surface-Energy Plastics (LSEP):

Materials like PE and PP require:

- Pretreatment with corona or plasma to increase surface tension

- Formulations with adhesion-promoting monomers

- Dual-wavelength curing for deep material penetration

Metallic Substrates:

UV systems prevent reflective interference by:

- Using opaque inks that cure evenly on reflective surfaces

- Incorporating anti-oxidation additives for long-term bonding

Textured Surfaces:

Directional LED arrays ensure complete coverage on:

- Embossed papers

- Woven fabrics

- Micro-perforated materials

Best Practices for Maximum Adhesion

- Material Testing: Conduct peel tests (ASTM D3330) and cross-hatch adhesion checks

- Lamp Maintenance: Regularly clean reflectors and check irradiance levels

- Ink-Substrate Pairing: Work with chemists to match photoinitiator profiles

- Oxygen Inhibition Control: Use nitrogen inerting for deep-cure applications

The Future of UV Adhesion Technology

Emerging innovations like wavelength-adjustable LED arrays and nanoparticle-enhanced inks promise to push adhesion boundaries further. These advancements will help printers tackle next-gen substrates like biodegradable films and smart packaging materials without compromising speed or quality.

By integrating UV curing systems tailored to specific substrate requirements, print providers can deliver superior adhesion across all applications—from high-gauge industrial labels to ultrathin retail packaging. The key lies in understanding material science, optimizing equipment settings, and collaborating closely with ink suppliers. As substrate diversity grows, UV curing remains the linchpin for achieving reliability in an increasingly demanding market.