The world of label printing is dynamic. Brands demand vibrant graphics and durable finishes. Printers are constantly seeking ways to enhance efficiency and expand their capabilities. This pursuit has led to a growing interest in bridging different printing technologies. We’re seeing a fascinating convergence of flexographic and offset printing within the same print runs. This shift is often driven by the need for diverse effects and precise registration.

Flexography, or flexo printing, has long been a staple for labels. Its flexible plates are ideal for printing on a variety of substrates. These include films, foils, and paper. Flexo excels at high-speed production and handling irregular surfaces. It’s a workhorse for many packaging applications.

Offset printing, on the other hand, offers incredible detail and color fidelity. It’s known for its sharp dot reproduction and smooth gradients. Historically, offset was more common for commercial printing. However, advancements have made it a viable option for narrow-web label printing. This is especially true for applications requiring high-quality imaging.

The challenge arises when printers want to combine the strengths of both. Imagine a label needing the speed and substrate versatility of flexo. Then, it requires the fine detail and smooth tones of offset. This is where multi-process printing comes into play. It allows a single pass to incorporate elements from both technologies. This can significantly streamline production. It reduces the need for multiple print runs on different machines.

Historically, bridging these processes presented hurdles. One significant bottleneck was drying and curing the inks. Traditional curing methods often involved heat. This could be detrimental to heat-sensitive substrates. It also consumed considerable energy. Furthermore, heat curing could lead to ink migration issues or affect adhesive performance.

Enter UV curing technology. UV curing uses ultraviolet light to instantly solidify ink. This process is incredibly fast. It happens in a fraction of a second. This rapid curing is a game-changer for high-speed printing. It allows for immediate handling of printed materials. This eliminates drying delays. It also means inks stay where they are applied.

However, traditional mercury-based UV lamps have their own set of limitations. They generate significant heat. This brings back the substrate sensitivity problem. They also consume a lot of power. Mercury lamps have a shorter lifespan. They require frequent replacement. Disposal of mercury bulbs also presents environmental concerns.

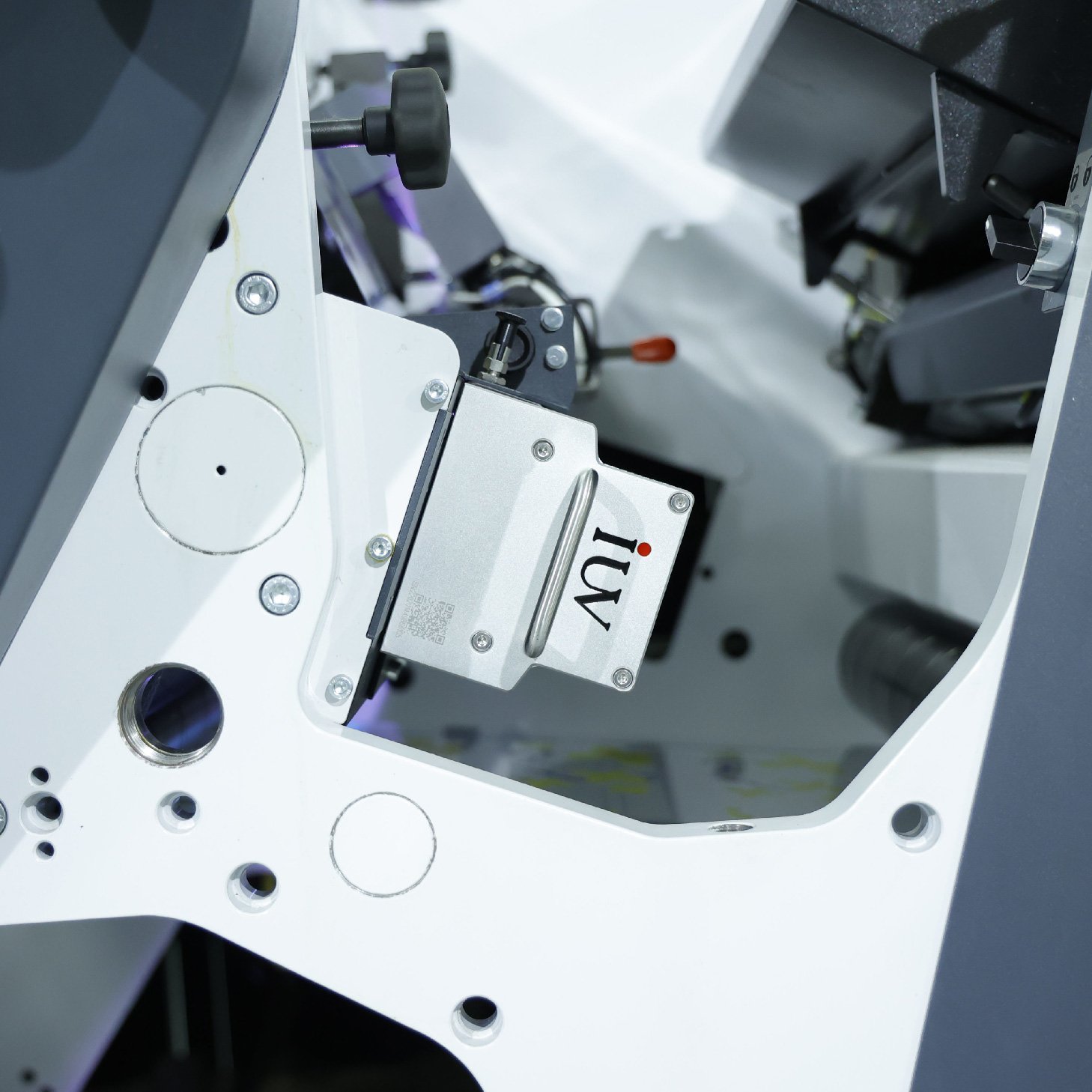

This is where Light Emitting Diode (LED) UV curing systems truly shine. LED UV curing represents a significant evolution in this technology. Instead of a broad spectrum of UV light, LEDs emit specific wavelengths. These wavelengths are precisely tuned to the photoinitiators within the UV ink. This targeted approach makes LED curing highly efficient.

The benefits of LED UV curing for multi-process printing are numerous. Firstly, and perhaps most importantly, they generate very little heat. This is a critical advantage for narrow-web printing. Many label substrates are thin films or delicate papers. The low heat output of LEDs prevents warping, shrinking, or discoloration of these materials. This opens up a wider range of printable substrates. It allows for more creative freedom in label design and material choice.

Secondly, LED systems are incredibly energy-efficient. They consume significantly less power than traditional mercury lamps. This translates directly into lower operating costs for print shops. The savings on electricity bills can be substantial over time. This economic advantage makes LED curing a more sustainable choice.

Thirdly, LED UV curing systems have an exceptionally long lifespan. They can operate for tens of thousands of hours. This is far longer than mercury lamps. This reduces downtime associated with bulb replacement. It also minimizes maintenance costs. The consistent performance of LEDs ensures reliable curing quality throughout their operational life.

Fourthly, the instant on/off capability of LEDs is a benefit in itself. Unlike mercury lamps that require warm-up time, LEDs are ready immediately. They also don’t degrade when switched off. This is perfect for intermittent printing operations. It further contributes to energy savings.

When combining flexo and offset printing on a narrow-web press, proper curing is paramount. Each printing station might require different ink formulations. Some inks might be optimized for flexo, others for offset. LED UV curing systems can be configured to emit the specific wavelengths needed for these diverse ink sets. This ensures consistent and thorough curing across all processes.

For example, a printer might use flexo for a base coat or a solid color. Then, they might switch to offset for fine text or a detailed photographic image. Each section needs to be cured effectively before the next stage. LED systems provide this capability reliably. They can be placed after each print unit or strategically positioned to cure multiple units at once.

The improved adhesion and scratch resistance offered by UV-cured inks are also critical for label applications. Labels are often handled, stacked, and exposed to various conditions. Robust curing ensures the ink stays intact. It prevents scuffing and fading. This preserves the brand’s integrity on the shelf.

The integration of LED UV curing systems into multi-process narrow-web presses is transforming the label printing landscape. It enables printers to offer a wider range of high-quality finishes. It allows them to do so with greater efficiency and reduced environmental impact. The ability to seamlessly blend flexo and offset printing, all while benefiting from the advantages of LED UV curing, empowers businesses to meet evolving market demands. This technology is a key enabler for innovation in label and packaging design. It provides the quality, speed, and versatility that brands require.