The printing industry is constantly evolving. New technologies emerge to improve efficiency and quality. UV curing is one such advancement. It uses ultraviolet light to instantly dry inks and coatings. This process offers several benefits over traditional drying methods. Two main types of UV curing systems dominate the market: mercury lamp systems and LED curing systems. Understanding their differences is key for any printer. This knowledge helps in choosing the right technology for specific applications.

Mercury lamp systems have been the standard for a long time. They use mercury vapor lamps to generate UV light. These lamps produce a broad spectrum of UV wavelengths. This makes them effective for curing a wide range of inks and coatings. For many years, they were the go-to choice for businesses. They offer reliable performance for various printing methods. This includes offset printing and flexography.

However, mercury lamps come with certain drawbacks. They generate a lot of heat. This can affect sensitive substrates. They also consume a significant amount of energy. Lamp replacement is another consideration. Mercury lamps have a limited lifespan. They need to be replaced periodically, adding to operational costs. Furthermore, mercury itself is a hazardous material. Its disposal requires special handling. This raises environmental concerns.

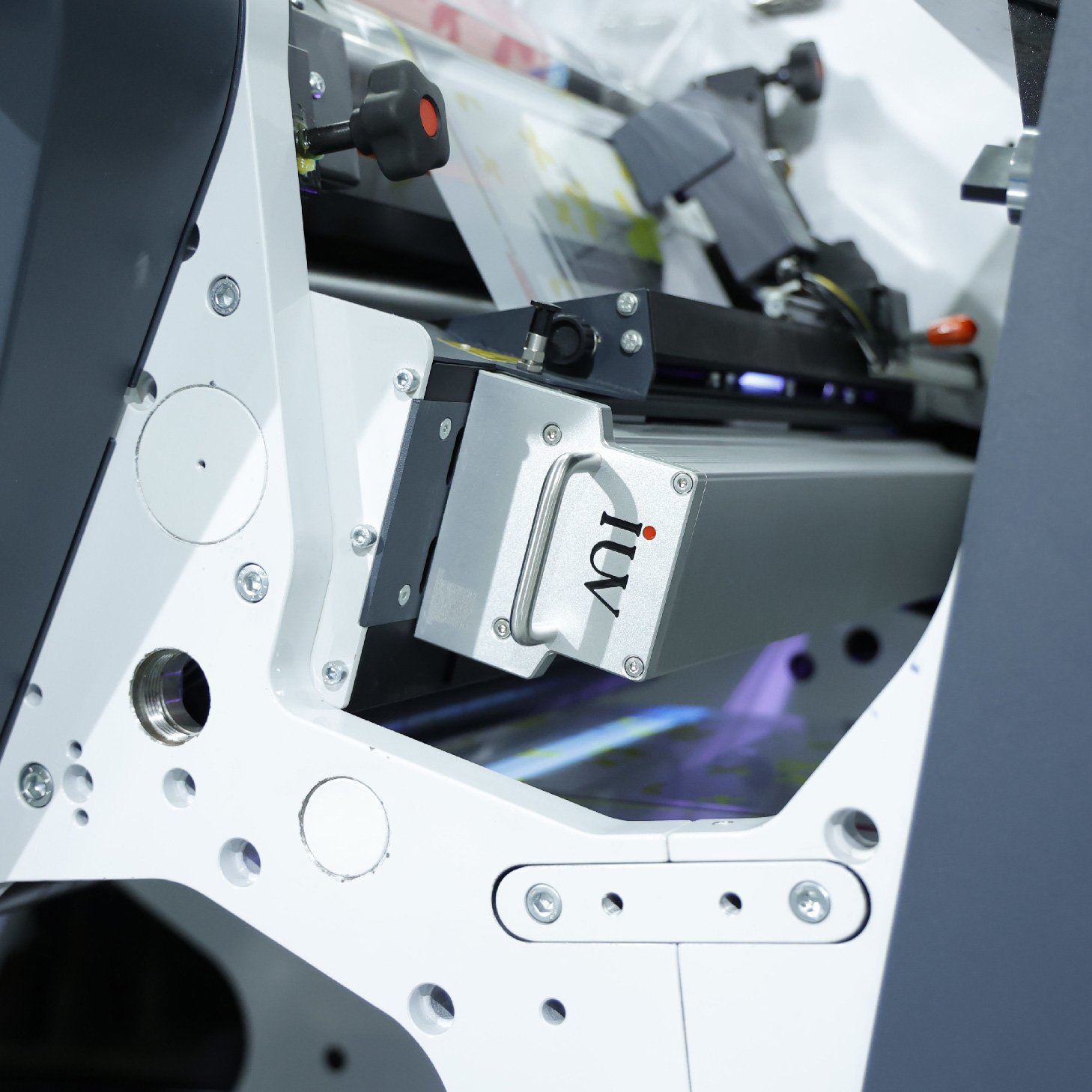

Enter LED curing systems. Light Emitting Diodes offer a modern alternative. They emit UV light at specific wavelengths. This precise emission is a major advantage. Different inks are formulated to cure under specific UV spectra. LED systems can be tailored to match these requirements. This leads to more efficient curing. It also reduces wasted energy.

The energy efficiency of LED systems is remarkable. They consume far less power than mercury lamps. This translates into lower electricity bills. It also reduces the overall carbon footprint of the printing operation. LED systems generate very little heat. This is a significant benefit for heat-sensitive materials. Think of thin films or delicate paper stocks. These can now be printed without distortion.

Another advantage of LEDs is their long lifespan. An LED module can last tens of thousands of hours. This is much longer than mercury lamps. It means fewer replacements and less downtime. Maintenance is also simplified. There are no fragile glass tubes to handle. The environmental impact is also positive. LEDs do not contain hazardous materials like mercury.

For narrow web printing, especially in the label and packaging sectors, LED curing is a game-changer. Label printers often work with a variety of substrates. They need fast and consistent curing. LED systems provide this. They ensure vibrant colors and sharp details. The reduced heat is also beneficial for continuous printing runs. It prevents the substrate from overheating. This maintains print quality throughout the job.

In flexographic printing, LED curing offers enhanced performance. Flexo printing is widely used for packaging and labels. LED systems ensure thorough curing of flexo inks. This is critical for ink adhesion and durability. The precise wavelength control can optimize ink performance. It leads to better print results. This is true even with challenging ink formulations.

Offset printing also benefits from LED technology. While offset printing has traditionally used mercury lamps, LED curing is making inroads. It offers faster drying times. This allows for higher press speeds. It also reduces the need for chillers. This simplifies the press configuration. It also lowers energy consumption. For narrow web offset, LED is a particularly attractive option.

The investment in LED curing systems can seem higher upfront. However, the long-term savings are substantial. Reduced energy costs, lower maintenance, and longer component life contribute to a strong return on investment. The enhanced print quality and ability to work with more delicate materials also add value.

When comparing the two, consider your specific printing needs. If you are primarily printing on robust substrates with standard inks, mercury lamps might still suffice. However, for applications requiring precise control, energy efficiency, and minimal heat, LED curing systems are the clear winner. The flexibility offered by LED technology makes it suitable for a wider range of future printing challenges. The future of UV curing is undeniably LED. It offers a cleaner, more efficient, and more versatile solution for the modern print shop.