High-volume printing demands speed and efficiency. Achieving both without compromising quality is a significant challenge. This is where UV curing systems become indispensable, especially for demanding applications like label printing, flexography, and offset printing. These advanced systems offer a transformative solution for narrow web printing and beyond.

The Challenge of Traditional Drying

For decades, printers relied on heat or air drying. This process is slow. It requires significant energy. It can also lead to substrate distortion, particularly with heat-sensitive materials common in label production. Furthermore, it often results in slower press speeds. This directly impacts production volume and profitability. Incomplete drying can cause ink smudging and poor adhesion. This leads to costly reprints and waste.

Enter UV Curing: A Revolution in Printing

UV curing technology utilizes ultraviolet light. This light triggers a photochemical reaction. This reaction instantly solidifies ink, coatings, or adhesives. This process is incredibly fast. It happens in milliseconds. The result is a fully cured, durable finish. This technology has revolutionized various printing sectors.

Benefits for High-Volume Label Printing

Label printing is a prime example of where UV curing excels. Labels often require vibrant colors, sharp details, and resistance to abrasion and chemicals. Traditional drying methods struggle to keep up with the high speeds of modern label presses. UV curing enables:

- Instant Drying: As soon as the ink or coating passes under the UV lamps, it cures. This eliminates waiting times.

- Vibrant Colors and Sharp Details: UV inks cure to a hard, glossy finish. This enhances color brilliance and image clarity. Fine text and intricate graphics remain exceptionally sharp.

- Durability: UV-cured inks and coatings are highly resistant to scratching, fading, and chemical damage. This is crucial for labels exposed to harsh environments.

- Substrate Versatility: UV curing works on a wide range of substrates. This includes papers, films, foils, and even plastics. Many of these are sensitive to heat. UV curing avoids this issue.

- Environmental Advantages: UV curing emits very few VOCs (Volatile Organic Compounds). This makes it a much greener printing solution compared to solvent-based inks.

Transforming Flexographic Printing

Flexography, a key process for packaging and labels, benefits immensely from UV curing. Flexo presses are designed for high speeds and continuous runs. UV curing aligns perfectly with this.

- Increased Press Speed: The instantaneous curing allows flexo presses to run at their maximum mechanical speeds. This dramatically boosts output.

- Improved Ink Transfer and Laydown: UV inks maintain their viscosity better under UV light. This leads to more consistent ink transfer and sharper dot definition on the press.

- Reduced Ink Consumption: The efficient curing means less ink is needed to achieve desired opacity and vibrancy.

- Enhanced Special Effects: UV coatings can be applied over UV inks to create high-gloss finishes, matte effects, or textured patterns. These add significant value to printed products.

Enhancing Offset and Sheetfed Printing

While offset printing traditionally used heat-set inks, UV curing has become increasingly popular, especially for short-run and high-value applications on sheetfed presses.

- Immediate Handling: Sheets are dry immediately after printing. This allows for instant stacking and finishing. No more waiting for ink to dry.

- Superior Finish: UV coatings provide exceptional gloss, scuff resistance, and protection. This elevates the perceived quality of the printed piece.

- Reduced Makeready Time: Less ink and coating management is required. This speeds up the transition between jobs.

- Cost Savings: Reduced spoilage and faster turnaround times contribute to significant cost efficiencies.

The Edge in Narrow Web Printing

Narrow web presses, commonly used for labels and flexible packaging, operate at very high speeds. UV curing is practically a necessity for these machines to reach their full potential.

- Uninterrupted Production: Instant curing prevents ink transfer or smudging between rollers or on subsequent webs. This ensures smooth, continuous production.

- Compact Footprint: UV curing units are generally more compact than traditional drying ovens. This is an advantage on space-constrained narrow web presses.

- Energy Efficiency: Compared to large heat-set drying tunnels, UV systems, especially LED UV, are significantly more energy-efficient.

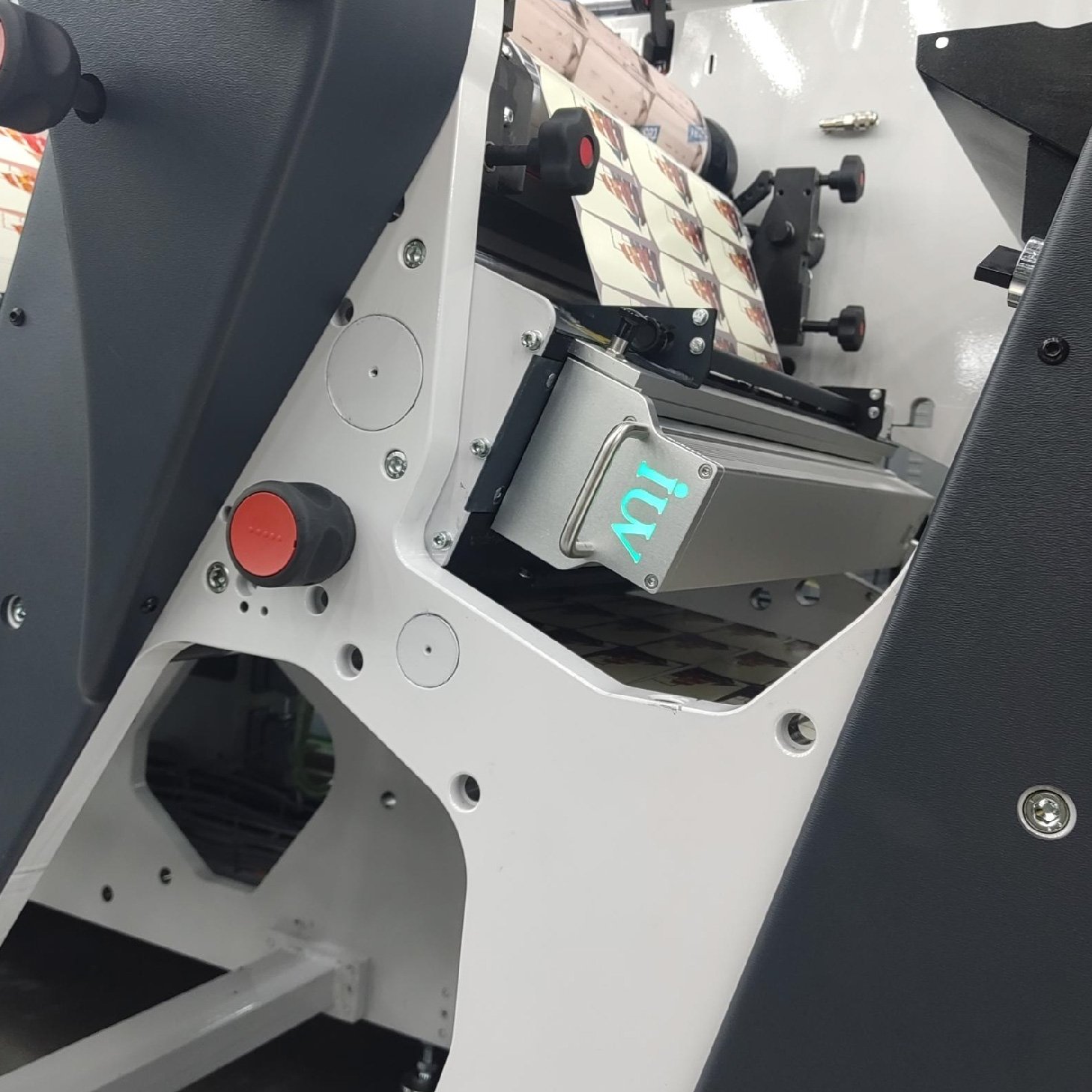

LED UV Curing: The Next Generation

The evolution of UV curing technology has brought us LED UV systems. These offer even greater advantages:

- Lower Energy Consumption: LEDs use a fraction of the energy of traditional mercury vapor lamps.

- Longer Lifespan: LED lamps can last tens of thousands of hours, drastically reducing replacement costs and downtime.

- Instant On/Off: Unlike mercury lamps that require warm-up and cool-down periods, LEDs are instantly operational. This saves energy and reduces heat load on the press.

- No Ozone Emission: LEDs emit no ozone, improving workplace air quality.

- Targeted Wavelengths: LEDs can be designed to emit specific UV wavelengths. This allows for highly efficient curing of specialized inks and coatings.

- Reduced Heat Transfer: LEDs generate much less heat transfer to the substrate. This is invaluable for delicate films and thin papers.

Conclusion: A Crucial Investment

For any printing operation focused on high volumes, consistent quality, and operational efficiency, UV curing systems are no longer a luxury. They are an essential component. Whether you’re in label printing, flexography, offset, or narrow web applications, the speed, durability, and versatility offered by UV technology, particularly LED UV, provide a competitive advantage. Embracing UV curing means embracing faster production cycles, superior product quality, and a more sustainable printing process. It’s an investment that pays dividends in every print run.