The world of printing is constantly evolving. We’re seeing new technologies emerge that promise better quality, faster speeds, and a reduced environmental impact. One such innovation that’s making waves, especially in label and flexible packaging, is UV curing. When we talk about the future of sustainable flexographic printing, UV curing, particularly LED UV curing, is right at the forefront.

Flexographic printing, often called “flexo,” is a workhorse for printing on a vast range of materials, from thin films to thick cardboard. It uses a flexible relief plate to transfer ink to the substrate. For years, solvent-based inks were the norm. These inks work by evaporating solvents, which can release volatile organic compounds (VOCs) into the atmosphere. While effective, VOCs are a concern for air quality and worker health.

Then came UV curable inks. These inks contain monomers and oligomers that, when exposed to ultraviolet (UV) light, polymerize rapidly, forming a solid ink film. This process is incredibly fast, meaning printers can run their presses at much higher speeds. Think about the efficiency gains! What used to take minutes can now take seconds. This speed translates directly into increased productivity and lower production costs.

Beyond speed, UV curing offers a significant sustainability advantage. Unlike solvent inks, UV inks contain little to no VOCs. This means a cleaner print shop environment and a much smaller environmental footprint. No more worrying about solvent emissions or the need for expensive and complex exhaust systems to capture them. It’s a win-win for both the printer and the planet.

Now, let’s dive a bit deeper into the technology itself. Traditional UV curing systems use mercury vapor lamps. These lamps are effective but have some drawbacks. They consume a lot of energy, generate a significant amount of heat, and their output can degrade over time, requiring frequent replacement. They also contain mercury, which poses its own environmental challenges.

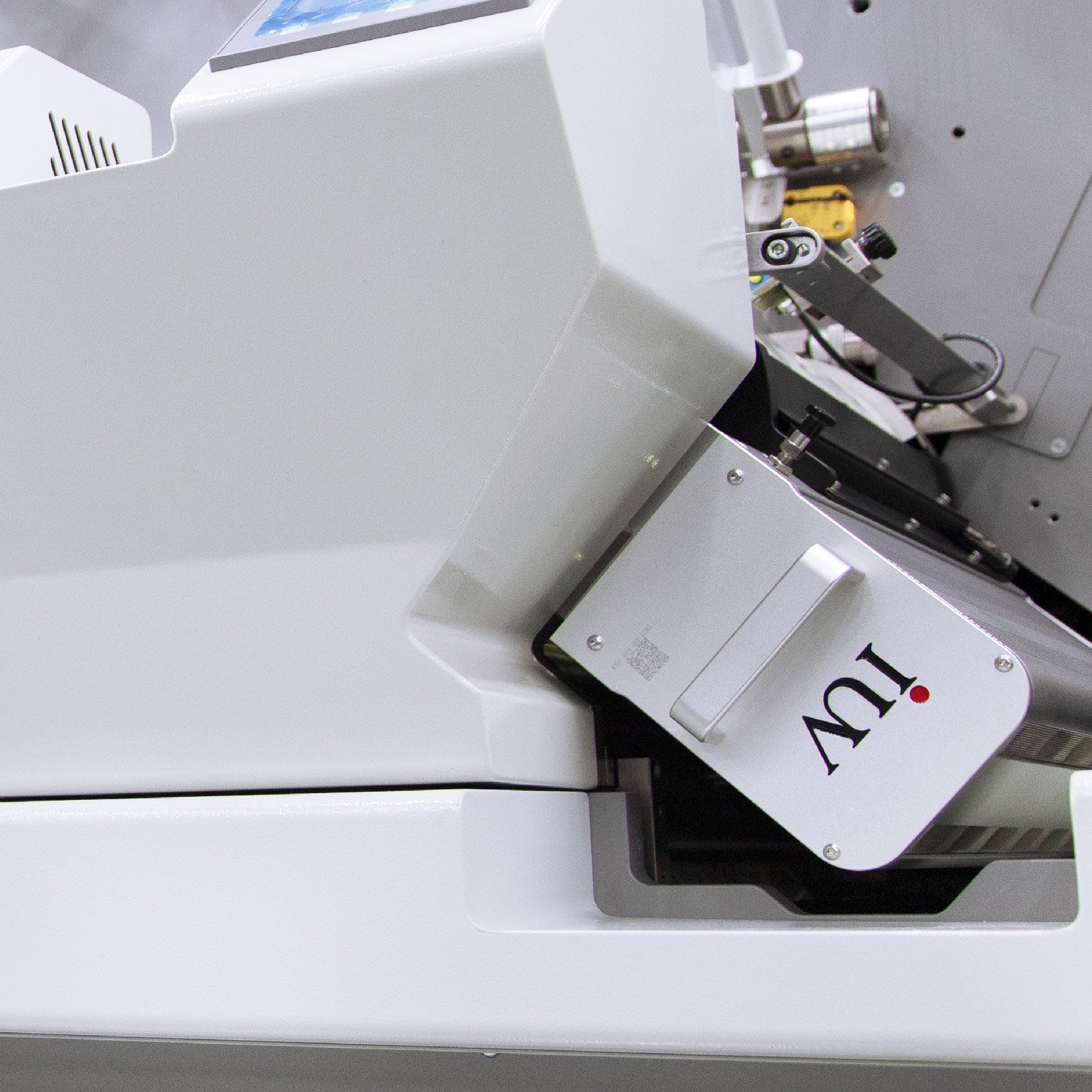

This is where LED UV curing truly shines and solidifies its position as the future. Light Emitting Diodes (LEDs) offer a more targeted and efficient way to cure UV inks. Instead of a broad spectrum of UV light, LEDs emit very specific wavelengths. This means the energy is delivered precisely where it’s needed for curing, leading to even greater efficiency.

The benefits of LED UV are numerous. Firstly, energy consumption is dramatically lower compared to mercury lamps. We’re talking about a significant reduction, which translates into substantial cost savings on electricity bills. Secondly, LEDs generate much less heat. This is a huge advantage when printing on heat-sensitive substrates, like thin plastic films, often used in flexible packaging and some labels. Less heat means fewer material distortions and better print quality control.

Thirdly, LED lamps have an incredibly long lifespan, often lasting tens of thousands of hours. This drastically reduces maintenance costs and downtime associated with lamp replacement. Imagine the convenience and cost savings of not having to change lamps every few hundred or thousand hours! Plus, LEDs are mercury-free, making them a much more environmentally friendly option.

When we talk about narrow web printing, which is where most labels and flexible packaging are produced, the impact of LED UV curing is particularly profound. The high speeds and the ability to print on a wide variety of substrates are critical in this market. LED UV allows printers to achieve vibrant colors, sharp details, and durable prints, all while minimizing their environmental impact.

The enhanced durability of UV cured inks is another key benefit. They are resistant to scratching, abrasion, and chemicals, which is crucial for labels that need to withstand handling, storage, and sometimes harsh environments. This means fewer rejected jobs and higher customer satisfaction.

Furthermore, UV curing enables innovative printing techniques. For example, the fast drying time of UV inks allows for multiple print stations in immediate succession. This opens up possibilities for complex multi-layer designs, spot UV varnishes, and tactile effects that can make a label or package stand out on the shelf. Think about adding a high-gloss finish or a raised texture to a label – UV technology makes this achievable with ease.

The transition to UV curing, and specifically LED UV, isn’t just about adopting new hardware. It also involves a shift in mindset towards more sustainable printing practices. As regulatory pressures increase and consumer demand for eco-friendly products grows, printers who embrace these technologies will be better positioned for the future.

For flexographic printing, especially in the label and packaging sectors, the integration of LED UV curing is not just a trend; it’s a fundamental shift towards a more efficient, higher-quality, and undeniably greener printing process. The combination of flexo’s versatility with the speed, quality, and sustainability of LED UV technology is what makes it the compelling future for the industry. It’s about printing smarter, cleaner, and better for years to come.