The landscape of narrow-web printing is undergoing a significant transformation. This shift is largely driven by the increasing demand for efficiency, sustainability, and superior print quality in the label and flexible packaging sectors. At the heart of this evolution lies the move towards fully automated UV production. Modern narrow-web printers are embracing this change, recognizing its profound impact on their operational capabilities and market competitiveness.

The Imperative for Automation in Narrow-Web Printing

For years, the narrow-web printing industry has operated with a degree of manual intervention. While this allowed for flexibility, it also presented challenges. Setup times could be lengthy, leading to increased waste and reduced throughput. Color matching, while mastered by skilled operators, often required painstaking adjustments. Furthermore, the physical demands on print staff could be considerable.

Automation addresses these inherent limitations. By integrating automated systems, printers can achieve faster job changeovers, reduce errors, and maintain consistent quality across extended print runs. This not only boosts productivity but also frees up skilled personnel to focus on higher-value tasks, such as process optimization and quality control.

The Role of UV Curing Technology

Ultraviolet (UV) curing technology has been a cornerstone of modern printing for decades, and its integration into narrow-web presses has been a key enabler of automation. UV curable inks and coatings offer rapid drying, or curing, when exposed to UV light. This instantaneous curing eliminates the need for extensive drying tunnels found in conventional printing processes.

The benefits of UV curing are multifaceted:

- Speed: Curing happens in seconds, allowing for faster press speeds.

- Quality: UV inks provide vibrant colors, excellent adhesion, and durable finishes.

- Versatility: They can be applied to a wide range of substrates, including films, foils, and papers.

- Environmental Advantages: UV inks are typically low in Volatile Organic Compounds (VOCs), contributing to a healthier print environment and reduced emissions.

The Evolution to LED UV Curing

While traditional mercury-vapor UV lamps have served the industry well, the advent of Light Emitting Diode (LED) UV curing technology has accelerated the move towards full automation. LED UV systems offer several distinct advantages that align perfectly with the goals of automated production:

- Energy Efficiency: LEDs consume significantly less energy than mercury lamps, leading to substantial cost savings on electricity.

- Longer Lifespan: LED lamps have a much longer operational life, reducing maintenance and replacement costs.

- Instant On/Off: LEDs can be switched on and off instantaneously, generating less heat and allowing for more precise control during job setup and purging. This is critical in an automated workflow.

- Lower Heat Emission: The reduced heat output from LEDs minimizes substrate distortion, especially important for heat-sensitive films.

- Durable and Compact: LEDs are solid-state devices, making them more robust and less prone to breakage. Their compact size also allows for easier integration into press designs.

Fully Automated UV Production: The Synergy of Press and Curing

The true power of modern narrow-web printing lies in the synergistic integration of advanced press technology with fully automated UV production, particularly LED UV. This integration eliminates bottlenecks and manual touchpoints throughout the printing process.

Consider the typical workflow in a fully automated UV production environment:

- Automated Setup and Job Management: Pre-press data is directly loaded into the press control system. This includes all job parameters, ink formulations, and color targets. Automated registration systems and impression setting minimize manual adjustments.

- Automated Ink Management: Closed-loop ink systems ensure consistent ink delivery, automatically adjusting viscosity and supply as needed. This prevents operator intervention and maintains color consistency.

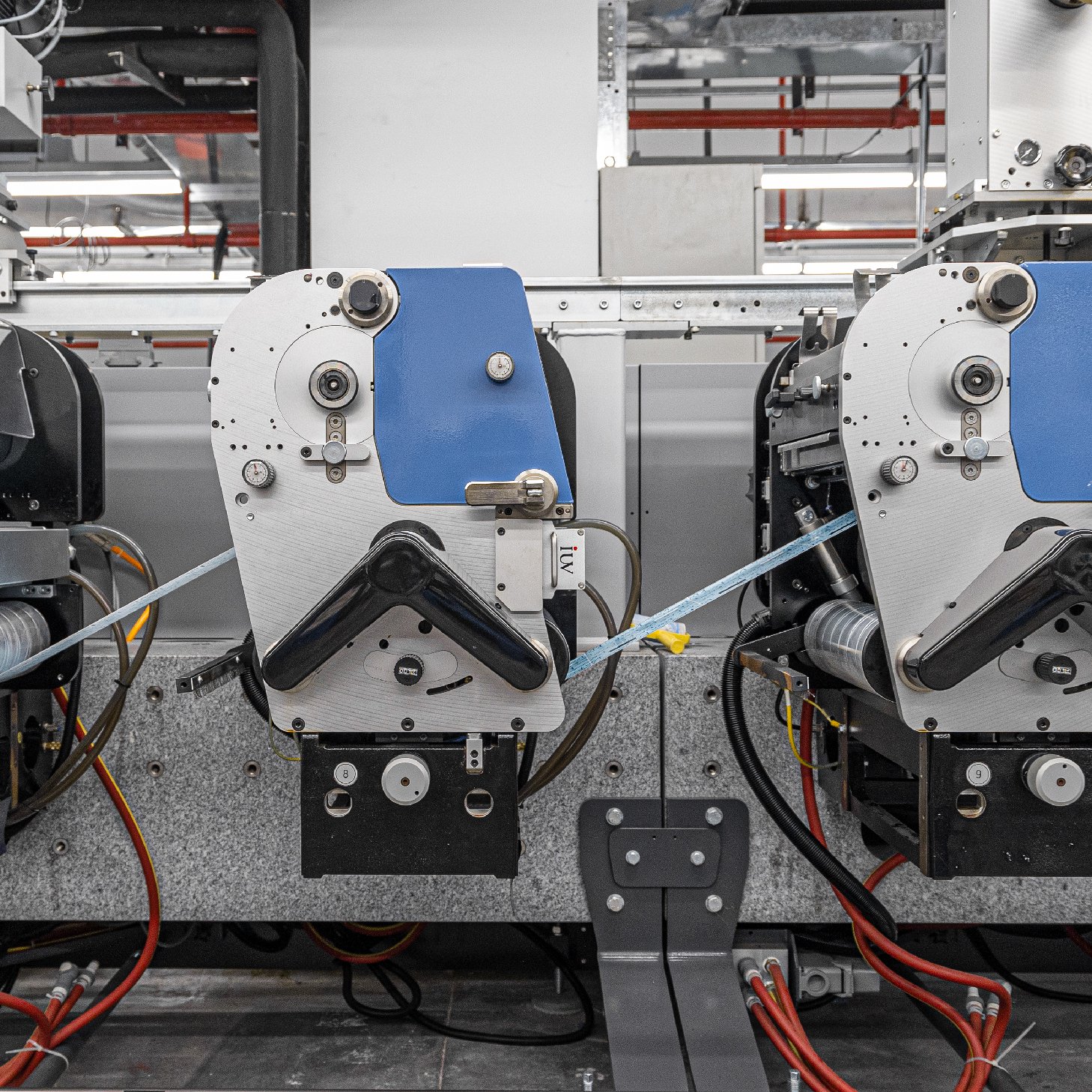

- UV Curing Integration: LED UV curing units are seamlessly integrated at each print station. Their instant on/off capability means they only activate when needed, reducing energy consumption and heat buildup. The precise control over UV output ensures optimal curing for each specific ink or coating.

- Automated Quality Control: In-line inspection systems can monitor print quality in real-time, detecting defects such as misregistration, hickeys, or color deviations. If an issue is detected, the system can automatically flag it or even halt production for intervention.

- Automated Waste Management: Efficient job changeovers minimize the amount of waste generated during setup. Automated rewind and slitting operations further streamline the finishing process.

Benefits for Different Printing Technologies

This shift towards fully automated UV production impacts various narrow-web printing technologies:

- Flexographic Printing: Flexo presses, known for their speed and versatility, benefit immensely from automation. Automated registration, impression control, and LED UV curing allow for faster job changes and consistent high-quality output, especially for packaging and labels. The ability to print on a wide range of substrates is further enhanced by the reliability of UV curing.

- Offset (Sheetfed