Flexographic printing, often called flexo, is a versatile printing method. It uses flexible printing plates to transfer ink onto a substrate. This process is widely used for packaging, labels, and other flexible materials. However, traditional curing methods can pose challenges, especially when printing on heat-sensitive substrates. This is where LED UV curing systems shine. They offer a superior solution for low-temperature flexo printing needs.

The Challenge of Heat in Flexo Printing

Traditional UV curing systems use mercury vapor lamps. These lamps generate significant heat. While effective for drying ink, this heat can be detrimental. Many modern printing substrates, such as thin films and certain plastics, cannot withstand high temperatures. Excessive heat can cause these materials to warp, shrink, or even melt. This leads to print defects and material waste. For label printers working with narrow web presses, maintaining precise control over temperature is paramount. It ensures the integrity of both the substrate and the final printed product.

Introducing LED UV Curing Technology

LED UV curing systems represent a significant advancement. They utilize Light Emitting Diodes (LEDs) to produce UV light. Unlike mercury lamps, LEDs emit a very narrow spectrum of UV wavelengths. More importantly, they generate minimal heat. This is a game-changer for flexographic printing. The controlled wavelength output also means higher energy efficiency and a longer lamp life. This technology is particularly beneficial for narrow web flexo operations. These operations often require precise ink drying without compromising substrate quality.

Advantages for Low-Temperature Flexo Printing

The primary advantage of LED UV systems in low-temperature flexo printing is their cool operation. This allows printers to work with a wider range of heat-sensitive materials. Delicate films, thin paper stocks, and certain polymer-based substrates can be printed without the risk of heat-induced damage. This expands the creative possibilities for label designers and manufacturers. They can now explore materials that were previously off-limits due to thermal limitations.

Furthermore, the consistent energy output of LEDs ensures uniform ink curing. This translates to sharper dot definition and better color vibrancy. In narrow web printing, where precision is key, this consistency is invaluable. It helps achieve high-quality, repeatable results across long print runs. The focused spectrum of LED UV light also means that the ink cures more efficiently. This can lead to faster printing speeds.

Cost-Effectiveness and Sustainability

Beyond performance, LED UV curing systems offer economic and environmental benefits. Their energy efficiency is remarkable. They consume significantly less power than traditional mercury lamps. This leads to lower electricity bills for printing businesses. The long lifespan of LED lamps also reduces maintenance and replacement costs. Mercury lamps require frequent replacement, adding to operational expenses and contributing to waste.

The reduced energy consumption also means a smaller carbon footprint. This aligns with the growing demand for sustainable printing practices. Many brand owners are actively seeking eco-friendly packaging and labeling solutions. By adopting LED UV technology, flexo printers can position themselves as environmentally responsible partners. This can be a strong selling point in a competitive market. For narrow web label converters, embracing sustainability can open new doors to environmentally conscious clients.

Enhanced Curing Performance

LED UV technology enables specific curing profiles. The precise wavelengths emitted by LEDs can be tailored to match the absorption characteristics of different UV inks. This means optimized curing for various ink formulations, including those designed for flexo and offset printing applications. The result is a more robust and durable ink film. This is crucial for labels that need to withstand abrasion, chemicals, and environmental exposure.

The focused nature of LED UV light also minimizes heat transfer to the substrate. This is particularly important for multi-layer applications or when printing on clear films where ink clarity is essential. The absence of ozone generation, a byproduct of mercury lamps, also contributes to a safer working environment. This is an important consideration for any printing facility.

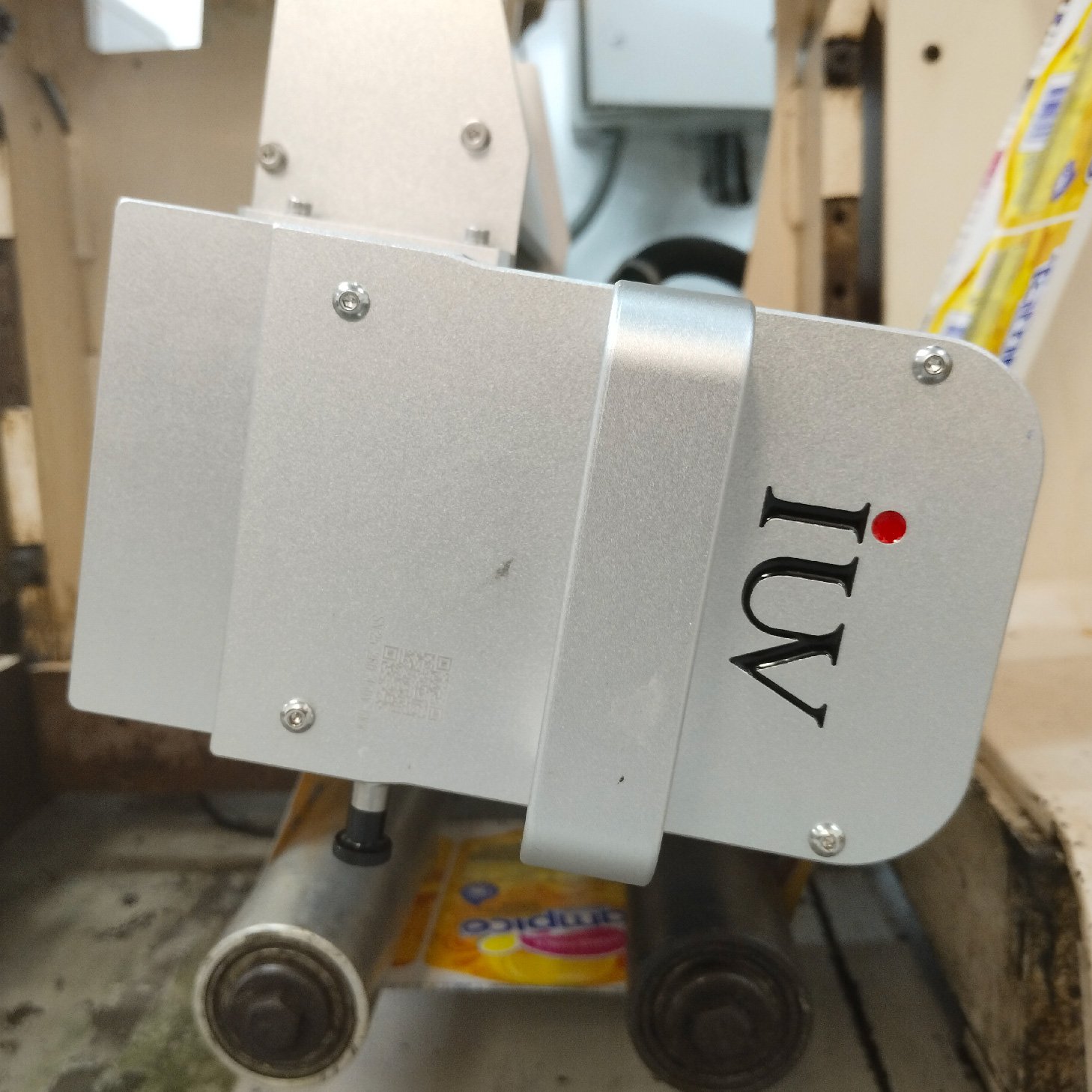

Integration into Existing Presses

One of the practical advantages of LED UV curing is its adaptability. Systems are available that can be retrofitted onto existing narrow web flexo presses. This allows printers to upgrade their capabilities without investing in entirely new machinery. The compact design of LED units often makes them easier to install. They require less ventilation compared to their mercury lamp predecessors. This simplifies the integration process and minimizes disruption to production schedules.

Choosing the Right LED UV System

When selecting an LED UV curing system for flexo printing, several factors come into play. The required UV intensity, wavelength spectrum, and curing area are critical. Printers need to consider the types of inks they use and the substrates they print on. Consulting with equipment manufacturers is advisable. They can help determine the most suitable system for specific application needs. For label printers, understanding the nuances of narrow web requirements is essential.

The benefits extend to both UV flexo and UV offset printing. However, the low-temperature advantage is particularly pronounced in flexo. This is due to the prevalence of heat-sensitive substrates in the label and flexible packaging sectors.

The Future of Flexo Curing

LED UV curing technology is rapidly becoming the standard for flexographic printing. Its ability to deliver high-quality results while minimizing heat and energy consumption is unmatched. As the technology continues to evolve, we can expect even greater efficiency and performance. The trend towards sustainable and cost-effective printing solutions further solidifies the position of LED UV curing. It is an investment that pays dividends in terms of print quality, operational efficiency, and environmental responsibility. For businesses in the narrow web printing space, embracing this technology is not just an upgrade; it’s a strategic imperative for future success.

The combination of advanced LED technology and the inherent versatility of flexography makes for a powerful printing solution. This is especially true when the focus is on delivering exceptional results on delicate materials. The benefits are clear for any printing operation prioritizing quality, efficiency, and sustainability.