The Dawn of Sustainable Printing: Embracing LED UV Curing

The printing industry is undergoing a significant transformation. As global demand for eco-friendly practices grows, so does the urgency to adopt sustainable technologies. Among these, LED UV curing stands out as a game-changer. This innovative technology offers remarkable benefits for various printing applications, from narrow web label printing to flexible packaging. It’s not just a trend; it’s the future of responsible printing.

Understanding UV Curing: A Quick Primer

Before diving into LED UV, let’s briefly touch upon traditional UV curing. This process uses ultraviolet light to instantly dry (or “cure”) inks, coatings, and adhesives. As soon as the UV light hits the specially formulated inks, a photochemical reaction occurs, transforming the liquid into a solid, durable film. This offers instant drying, high gloss, and excellent scratch resistance.

The Limitations of Traditional UV Systems

Traditional UV curing systems typically employ mercury vapor lamps. While effective, these lamps have several drawbacks. They consume significant amounts of energy, generate substantial heat, and have a relatively short lifespan. Mercury lamps also require careful disposal due to their hazardous nature. This all adds to the environmental footprint and operational costs of a printing business.

Enter LED UV Curing: A Greener, Smarter Solution

LED UV curing technology utilizes light-emitting diodes (LEDs) instead of mercury lamps. LEDs emit UV light within very specific wavelengths. This targeted emission is a key advantage. It means less wasted energy and a more efficient curing process. The difference is profound, impacting everything from operational costs to environmental sustainability.

Environmental Advantages of LED UV

The sustainability benefits of LED UV curing are compelling. Firstly, LEDs are incredibly energy-efficient. They consume up to 80% less energy compared to traditional mercury lamps. This drastically reduces electricity bills and lowers a printer’s carbon footprint. Secondly, LEDs produce much less heat. This means less strain on cooling systems and a more comfortable working environment. Thirdly, LED lamps are mercury-free. This eliminates the need for hazardous waste disposal, contributing to safer and cleaner operations.

Performance Prowess: Beyond Sustainability

LED UV curing isn’t just about being green; it significantly enhances print quality and performance. The precise wavelength control of LEDs ensures consistent and thorough ink curing. This results in vibrant colors, sharp details, and superior adhesion. Printers can achieve a wider gamut of colors and reproduce intricate designs with remarkable accuracy.

Perfect for Narrow Web Label Printing

Narrow web label printing is a prime area where LED UV shines. Labels often require vibrant graphics, durable finishes, and fast production speeds. LED UV curing perfectly aligns with these demands. The instant curing allows for high-speed printing and immediate finishing. This means labels are ready for application or shipment faster than ever. Furthermore, the low heat output of LEDs is ideal for heat-sensitive substrates commonly used in label production.

Enhancing Flexographic Printing Processes

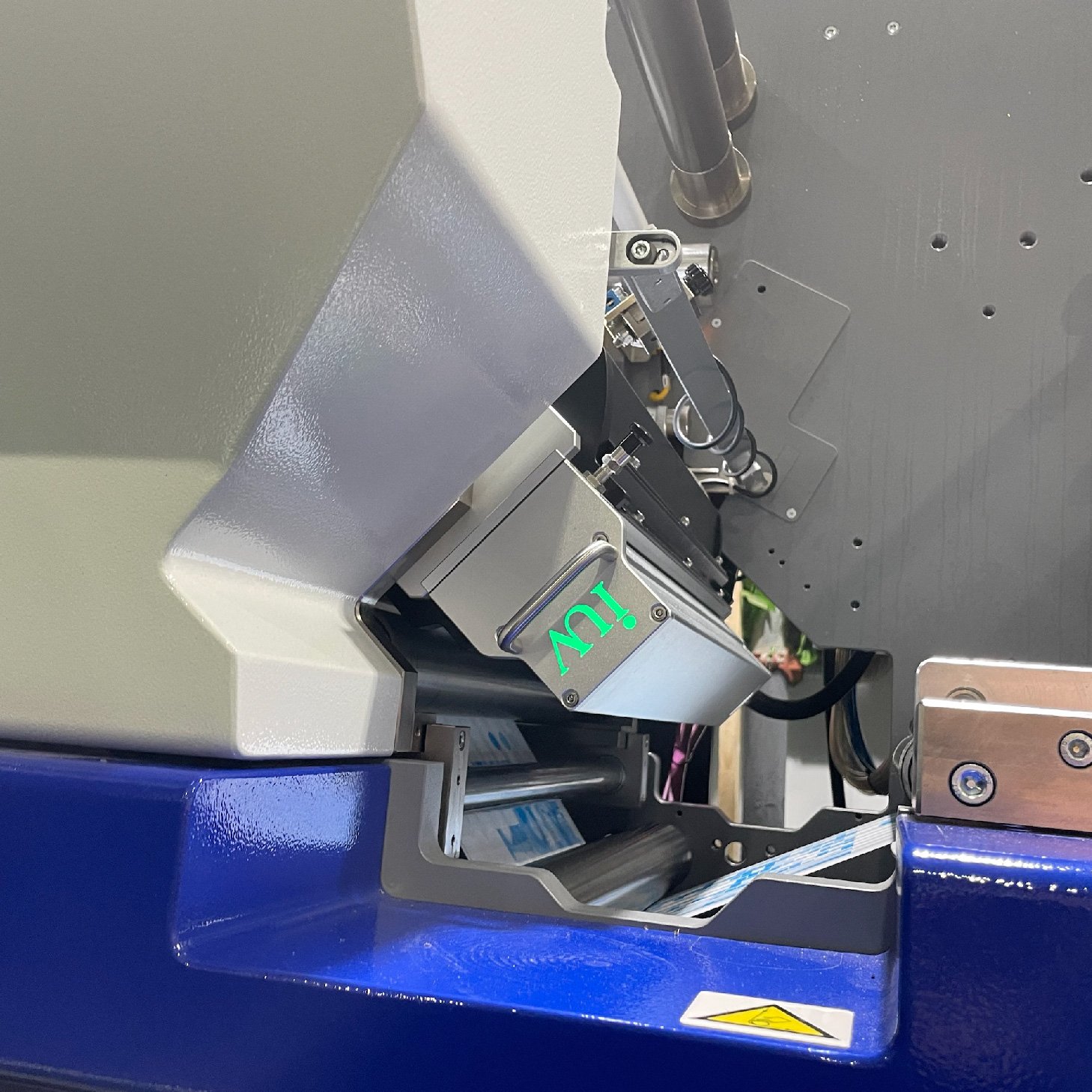

Flexographic printing, particularly in packaging and labels, benefits immensely from LED UV. Flexo presses can be retrofitted with LED UV curing units. This upgrade brings the advantages of energy savings, reduced heat, and faster speeds. The consistent curing ensures excellent ink transfer and a durable final product, crucial for high-volume packaging runs.

Optimizing Offset Lithographic Printing

Offset printing, often referred to as offset lithography, also sees significant improvements with LED UV. In sheetfed and web offset, LED UV allows for instant drying of inks and coatings on a wide range of papers and boards. This eliminates waiting times for drying, enabling immediate post-press operations like cutting and folding. The reduced heat is also beneficial for paper-based substrates.

Benefits Across Various Printing Applications

The versatility of LED UV curing extends beyond labels and packaging. It’s equally valuable for commercial printing, direct mail, and specialty printing applications. Whether it’s high-gloss coatings on brochures or durable finishes on promotional materials, LED UV delivers exceptional results. It opens up new possibilities for printing on diverse substrates, including plastics and metallic foils.

Reduced Operational Costs and Increased Throughput

The operational advantages of LED UV curing translate directly into cost savings. Lower energy consumption means reduced utility bills. Longer lamp life compared to mercury lamps means fewer replacements and less downtime. The instant drying capability allows for faster job completion and increased press throughput. This boosts overall productivity and profitability.

The Future is Bright, and It’s Cured by LED UV

The shift towards LED UV curing is more than just adopting new hardware. It’s an investment in a more sustainable, efficient, and higher-quality printing future. As regulations tighten and customer demand for eco-friendly products increases, businesses that embrace LED UV will undoubtedly lead the way. This technology is no longer a luxury; it’s a necessity for forward-thinking printing operations.