The packaging industry is constantly evolving. Staying competitive means embracing new technologies that improve efficiency, quality, and sustainability. For packaging converters, one of the most significant advancements in recent years has been the widespread adoption of LED UV curing systems. These systems are not just a trend; they are becoming an essential component for modern operations, especially in label printing and other narrow web applications.

The Shift Towards LED UV Curing

For a long time, traditional mercury vapor lamps were the standard for UV curing in the printing world. While they did the job, they came with a host of drawbacks. They consumed a lot of energy, generated substantial heat, and had a limited lifespan, requiring frequent replacement. This constant maintenance and high energy consumption added significant costs to production.

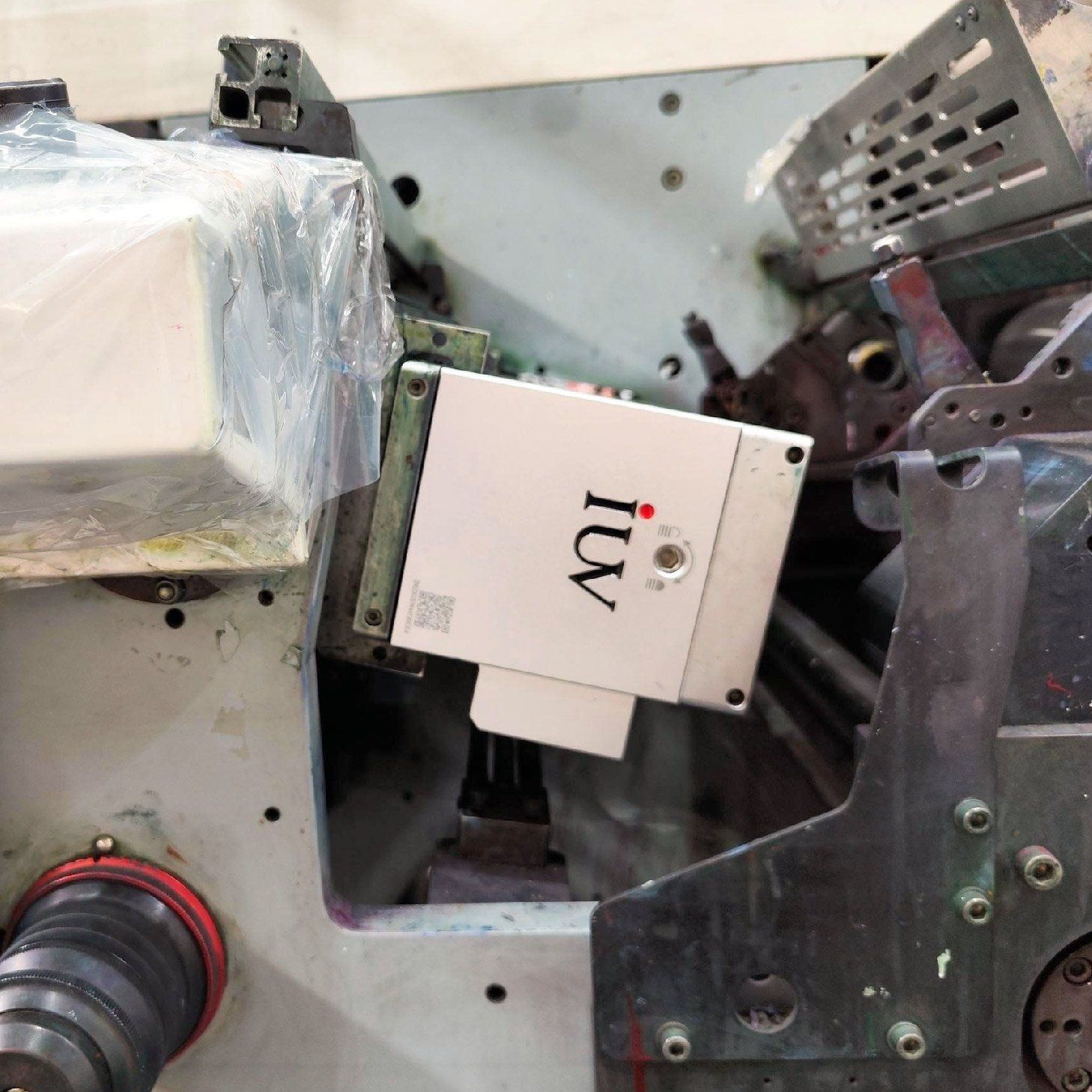

LED UV curing technology offers a superior alternative. Instead of relying on a broad spectrum of UV light, LEDs emit specific wavelengths that are precisely matched to the photoinitiators in UV-curable inks and coatings. This targeted approach means more efficient energy transfer, leading to faster and more complete curing.

Benefits for Label Printing and Narrow Web Converters

Label printing and narrow web converters, in particular, benefit immensely from LED UV curing. These operations often involve high-speed printing with a variety of substrates, including heat-sensitive materials.

Energy Efficiency: LED systems are remarkably energy-efficient. They use significantly less power than mercury lamps, translating directly into lower electricity bills. Furthermore, LEDs consume power only when they are on, unlike mercury lamps which need to warm up and stay on, even during brief pauses in production.

Reduced Heat Output: One of the most critical advantages for narrow web printing is the reduced heat output from LED systems. Traditional lamps generate a lot of heat, which can cause heat-sensitive substrates like thin films or certain papers to warp, shrink, or even melt. This limits the types of materials that can be printed and can lead to costly material waste. LEDs, on the other hand, emit very little infrared radiation, keeping the substrate temperature low and stable. This opens up a wider range of material options and improves print quality by preventing distortion.

Instant On/Off: LEDs turn on and off instantly. This is a huge advantage in short-run printing environments or when dealing with frequent setup changes. There’s no warm-up or cool-down period, allowing for immediate full-power curing as soon as the print head is running and immediately switching off when it stops. This minimizes wasted energy and reduces the risk of over-curing or ink pooling on the substrate during setup.

Longer Lifespan and Lower Maintenance: LED UV lamps have a much longer operational lifespan compared to mercury lamps. While mercury lamps typically last around 1,000-2,000 hours, LEDs can last 20,000 hours or more. This drastically reduces downtime associated with lamp replacement and lowers overall maintenance costs. The consistent performance of LEDs also means less variability in curing results over time.

Improved Print Quality and Performance: The precise wavelength control of LED systems ensures efficient and consistent curing. This leads to sharper details, better ink adhesion, enhanced scratch and chemical resistance, and superior overall print durability. For packaging, where the printed image is often the first point of contact a consumer has with a product, these quality improvements are invaluable.

Environmental Advantages: The energy efficiency of LEDs contributes to a smaller carbon footprint for packaging converters. The absence of mercury in LED lamps also makes them an environmentally friendlier choice, simplifying disposal and reducing hazardous waste.

LED Curing in Different Printing Processes

While often associated with flexographic printing for labels and flexible packaging, LED UV curing is also making inroads into offset (sheetfed and web) and gravure printing processes, although it’s most established in narrow web flexo.

Flexographic Printing: This is where LED UV curing has seen its most rapid adoption in packaging. Flexo presses are designed for high-speed, high-volume production. The ability of LEDs to cure inks instantly without significant heat buildup is perfectly suited for the demands of flexo, especially when printing on flexible films and sensitive label stocks. This enables converters to achieve vibrant colors, sharp text, and excellent adhesion, even at high press speeds.

Offset Printing: In narrow web offset, LEDs allow for faster throughput and the use of heat-sensitive substrates that might not be compatible with traditional IR or hot air drying. The precise control of UV output also helps in achieving consistent color and finish across the print run.

Gravure Printing: While less common currently, the potential for LED UV curing in gravure is being explored, especially for applications that require fast drying and excellent resistance properties. The key challenge is adapting the existing gravure cylinder technology and ink formulations to optimize for LED curing.

The Importance of Ink and Coating Formulation

It’s important to remember that the effectiveness of LED UV curing relies heavily on properly formulated inks and coatings. These formulations must contain photoinitiators that are sensitive to the specific wavelengths emitted by the LEDs (typically in the 365 nm, 385 nm, 395 nm, or 405 nm range). Many ink manufacturers now offer a wide range of LED-curable inks and coatings specifically designed for different printing processes and applications. Choosing the right ink system is as crucial as choosing the right curing technology.

Future Trends and Conclusion

The trend towards LED UV curing systems in the packaging industry is undeniable. As the technology matures and the benefits become more widely recognized, it is expected to become the de facto standard for UV curing. For packaging converters looking to enhance their production capabilities, improve print quality, reduce operational costs, and embrace more sustainable practices, investing in LED UV curing systems is no longer an option – it’s an essential step towards future success. The ability to handle a wider range of substrates, achieve faster production speeds, and deliver higher quality finishes makes LED technology a true game-changer in the competitive world of modern packaging production.