The flexographic printing industry is in the midst of a significant transformation, driven largely by the adoption of LED UV curing technology. This shift is not merely an upgrade; it’s a revolution that offers tangible benefits across various printing applications, from intricate labels to wide-format packaging. For narrow web printers, in particular, the advantages are profound, impacting efficiency, sustainability, and print quality.

Traditionally, flexo printing relied on mercury vapor lamps for UV curing. While effective, these lamps came with a host of drawbacks. They generated considerable heat, impacting substrate choices and potentially causing warping. Their energy consumption was high, and they required frequent replacement due to a limited lifespan and the need for consistent power output. The environmental impact and operational costs associated with mercury lamps were also substantial.

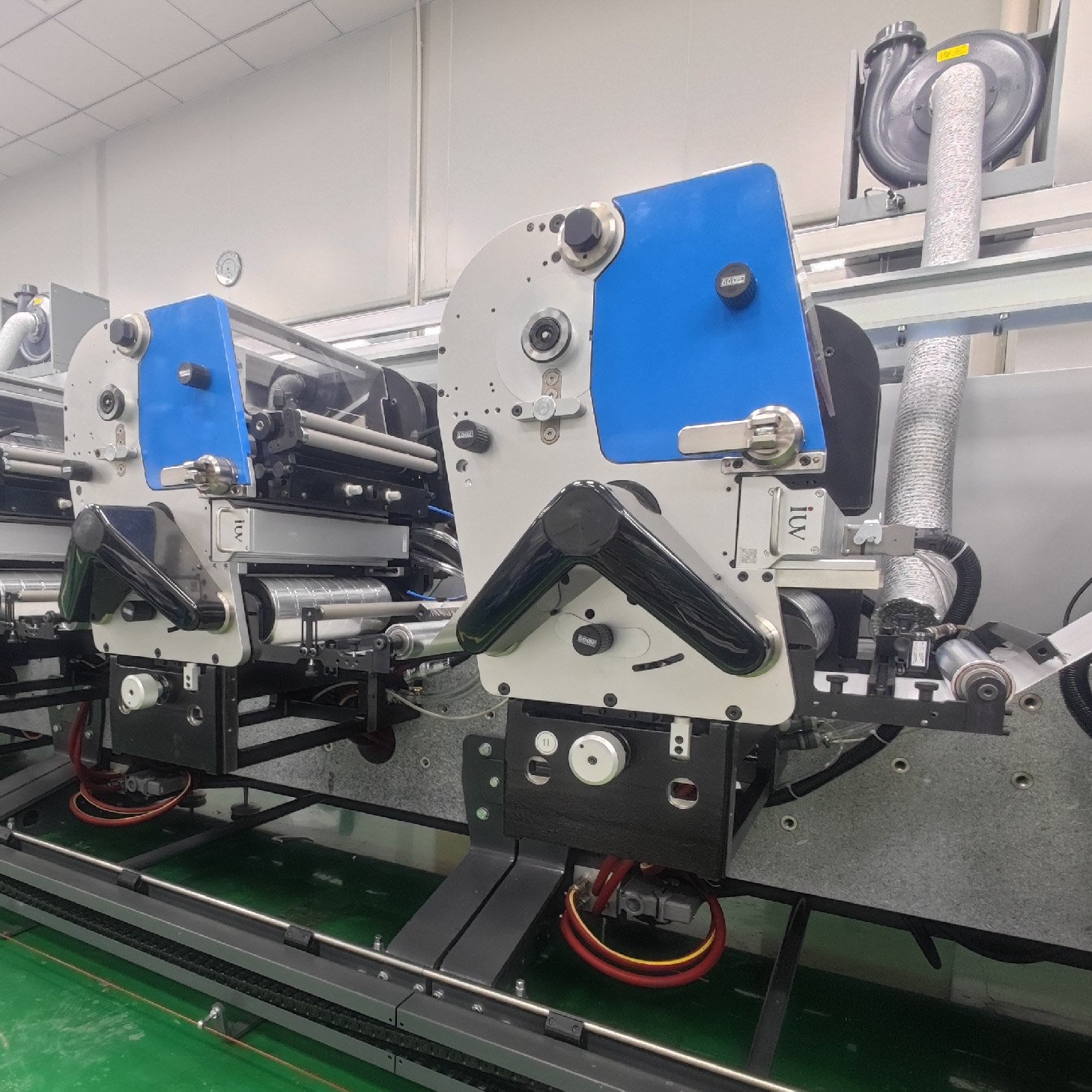

Enter LED UV curing. This innovative technology utilizes light-emitting diodes (LEDs) to generate UV light. The difference is night and day. LEDs emit light at specific wavelengths, precisely tuned to activate photoinitiators in UV-curable inks, coatings, and adhesives. This targeted approach means more efficient energy transfer and a faster, more complete cure.

The Advantage for Label Printing

In the competitive world of label printing, speed and quality are paramount. LED UV curing excels here. Because LEDs produce much less heat than mercury lamps, printers can run their presses at higher speeds without the risk of overheating delicate or sensitive substrates like thin films or certain plastics. This allows for increased throughput and faster turnaround times, a crucial factor for meeting demanding client deadlines.

Furthermore, the consistent output of LED lamps ensures a reliable and thorough cure, even at high speeds. This translates to sharper print definition, brighter colors, and superior adhesion. Labels printed with LED UV curing exhibit excellent scratch and chemical resistance, meeting the rigorous demands of product packaging across diverse industries, from food and beverage to pharmaceuticals and personal care. The ability to achieve a high-quality, durable print without compromising speed is a game-changer for label converters.

Broadening Horizons in Flexographic Printing

While narrow web printing has been an early adopter, the benefits of LED UV curing are extending to wider flexographic applications. Packaging printers are finding that LED technology opens up new possibilities. The reduced heat output allows for the printing on a wider range of packaging materials, including heat-sensitive films and boards, which were previously challenging or impossible to print on with traditional UV systems.

This expanded substrate capability means greater flexibility in material selection, potentially leading to cost savings and enhanced product appeal. The consistent and efficient curing also contributes to improved print consistency across large runs, reducing waste and ensuring brand colors are reproduced accurately and vibrantly, time after time.

Ink and Coating Innovations

The synergy between LED UV curing and ink formulations is another key aspect of this transformation. Manufacturers have developed specialized LED-curable inks and coatings that are specifically designed to react to the precise wavelengths emitted by LED lamps. These formulations often offer improved performance characteristics, such as enhanced flexibility, higher gloss, and better adhesion to a wider array of substrates.

The faster curing times achieved with LED technology also allow for inline finishing processes. This means printers can apply coatings, varnishes, or even laminates immediately after printing, all within the same press run. This significantly streamlines production workflows, reduces handling, and ultimately lowers manufacturing costs. The capability to perform multiple operations in a single pass is a powerful efficiency driver.

Sustainability and Cost-Effectiveness

Beyond performance enhancements, LED UV curing offers compelling environmental and economic advantages. LEDs are significantly more energy-efficient than mercury lamps, consuming up to 70% less power. This reduction in energy usage not only lowers electricity bills but also decreases the carbon footprint of the printing operation.

Moreover, LED lamps have a much longer operational lifespan, often lasting tens of thousands of hours compared to the few thousand hours of mercury lamps. This dramatically reduces the frequency of lamp replacements, saving on both material costs and the labor associated with maintenance. The absence of mercury in LED lamps also eliminates hazardous waste disposal concerns, aligning printing operations with growing sustainability mandates.

The reduced heat output from LED systems also means less demand on a facility’s cooling systems, leading to further energy savings. For printers looking to improve their environmental credentials and reduce operating expenses, the transition to LED UV curing is a clear and logical step.

Addressing Common Concerns

Some initial concerns about LED UV curing have been addressed through technological advancements. While early LED systems might have had limitations in terms of power output or wavelength flexibility, modern LED curing solutions offer robust performance across a wide spectrum of applications. The upfront investment in LED technology can be a consideration, but the long-term savings in energy, consumables, and maintenance, combined with increased productivity and print quality, typically provide a strong return on investment.

The Future is Bright

The integration of LED UV curing into flexographic printing is not a trend; it’s the future. It empowers printers to achieve higher quality, greater efficiency, and improved sustainability. For label printers, it means enhanced competitiveness and the ability to take on more demanding jobs. For the broader flexographic industry, it unlocks new substrate possibilities and streamlines production. As the technology continues to evolve, its impact will only grow, solidifying LED UV curing as a cornerstone of modern, high-performance flexographic printing.