When it comes to flexographic printing, especially in the narrow web and label sectors, achieving fast, efficient, and high-quality curing is paramount. You’re dealing with a wide range of substrates, demanding turnaround times, and the ever-present need for vibrant, durable prints. For years, traditional UV curing systems have been the go-to. These systems use mercury vapor lamps to emit UV light. They’ve served the industry well, offering a reliable way to instantly dry inks and coatings. This instant drying is a game-changer, preventing ink transfer and allowing for immediate handling and finishing of printed materials.

Traditional UV lamps operate by generating UV radiation through an electric arc across a mercury vapor. This process creates a broad spectrum of UV light, which effectively cures many types of UV-curable inks and coatings. The technology is mature, and equipment is readily available and often more affordable upfront. However, there are some distinct drawbacks to consider. Mercury lamps generate a significant amount of heat. This can be problematic when printing on heat-sensitive substrates like certain plastics or thin films. You might experience substrate distortion or even damage, limiting your material choices.

Another significant factor is the lamp’s lifespan and energy consumption. Mercury lamps have a limited operational life and degrade over time, meaning their UV output diminishes. This necessitates periodic replacement, adding to ongoing costs. Furthermore, they consume a considerable amount of energy, and a portion of that energy is lost as heat, which then needs to be managed by your ventilation system. This all adds up to higher operational expenses and a larger environmental footprint.

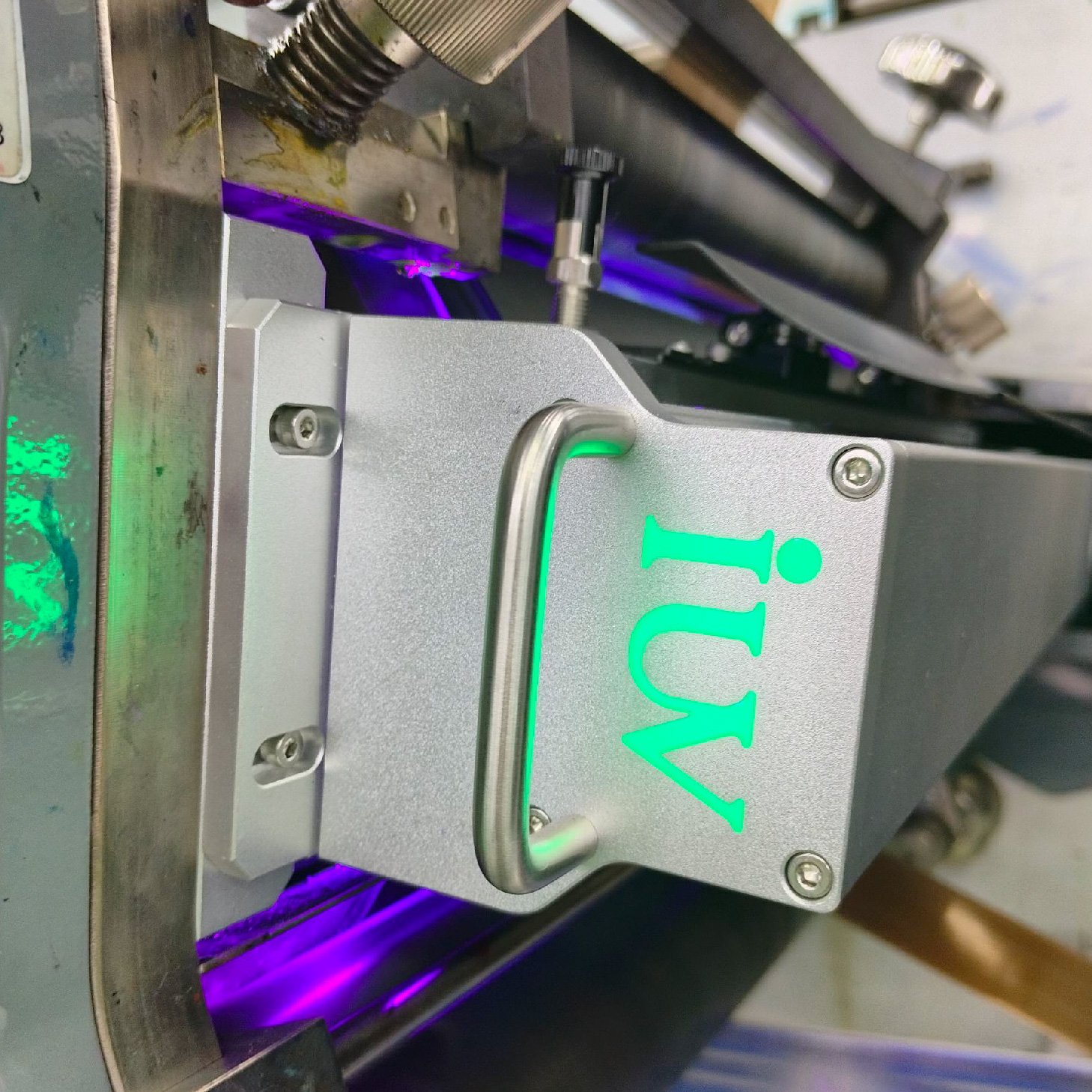

Enter LED UV curing technology. This is where things get really interesting, especially for flexographic printing. LED (Light Emitting Diode) UV curing uses solid-state semiconductor devices to emit UV light. Unlike mercury lamps, LEDs emit light in very specific, narrow wavelengths. This is a crucial difference. For instance, you can find LEDs tuned to emit at 365nm, 395nm, or other precise points in the UV spectrum. This wavelength specificity is key to achieving efficient curing with modern UV-curable inks and coatings designed specifically for LED technology.

The advantages of LED UV curing are compelling. First, and perhaps most importantly for many flexo printers, is the significantly reduced heat output. Because LEDs are so targeted in their light emission, they generate much less waste heat. This opens up a world of possibilities for printing on a wider variety of sensitive substrates without worrying about heat-related distortion or damage. Think of printing on thin films, shrink sleeves, or delicate papers where traditional UV would be a no-go.

Energy efficiency is another massive win for LED UV. LEDs are far more energy-efficient than mercury lamps. They consume less power to produce the same effective UV output, leading to lower electricity bills. Plus, because they don’t require a warm-up period like mercury lamps, they can be switched on and off instantly, further saving energy during downtimes. The operational cost savings can be substantial over the life of the equipment.

The lifespan of LED UV systems is also a major advantage. While mercury lamps might last a few thousand hours, LED arrays can often last 20,000 to 50,000 hours or even more. This drastically reduces maintenance costs and downtime associated with lamp replacements. You’re not constantly buying and swapping out bulbs. This reliability translates directly into more consistent production and less hassle.

When considering flexographic printing, the narrow web sector, which includes label printing, is a prime candidate for LED UV adoption. These presses often run at high speeds, and the instant curing capability of both UV technologies is essential. However, the ability of LED UV to handle a broader range of substrates and its lower energy consumption make it an increasingly attractive option, especially for printers looking to improve their sustainability metrics and reduce operational costs.

The inks and coatings are also evolving. For years, the industry relied on mercury-curable inks. Now, there’s a growing range of inks and coatings specifically formulated for LED UV curing. These inks are designed to cure optimally at the specific wavelengths emitted by LED lamps. Using the correct ink formulation with your LED system is critical to achieving fast, complete, and robust curing. If you’re looking at converting to LED UV, you’ll want to work closely with your ink supplier to ensure you have the right products.

Comparing the two systems head-to-head for flexographic printing, it’s not always a simple “one is better” answer, but the trend is undeniably moving towards LED. Traditional UV systems still have their place, especially if you’re on a tighter initial budget or primarily printing on robust substrates where heat isn’t a major concern. They offer a proven, reliable curing method.

However, if you’re looking for enhanced substrate flexibility, significant energy savings, a longer equipment lifespan, reduced maintenance, and a more environmentally friendly solution, LED UV curing is the clear winner. The upfront cost of LED systems can be higher, but the total cost of ownership, factoring in energy, maintenance, and substrate versatility, often makes it the more economical choice in the long run.

For narrow web and label printers, the ability to print on a wider variety of materials, achieve faster production speeds without heat-related issues, and reduce operational costs makes LED UV a powerful technology to consider. It’s an investment in efficiency, versatility, and future-proofing your flexographic printing operations. The precision of LED curing, combined with specially formulated inks, allows for incredibly sharp details and vibrant colors, meeting the high demands of the label market.