Choosing the right curing technology is a big decision for any printing operation. This is especially true in narrow web printing, where labels and flexible packaging demand speed, quality, and efficiency. Two primary technologies dominate the scene: traditional UV curing systems and the increasingly popular LED UV curing. Understanding their differences is key to selecting the best fit for your press.

Traditional UV curing systems use mercury vapor lamps. These lamps emit a broad spectrum of UV light. This light triggers the photoinitiators in UV-curable inks and coatings, causing them to harden, or cure, almost instantly. These systems have been the workhorse of the industry for decades. They offer robust performance and a proven track record.

However, mercury lamps come with several drawbacks. They generate significant heat. This heat can affect sensitive substrates, leading to warping or reduced print quality. They also consume a lot of energy. Lamp replacement is a recurring cost, and the disposal of mercury-containing lamps raises environmental concerns. Furthermore, their warm-up and cool-down times can impact press productivity.

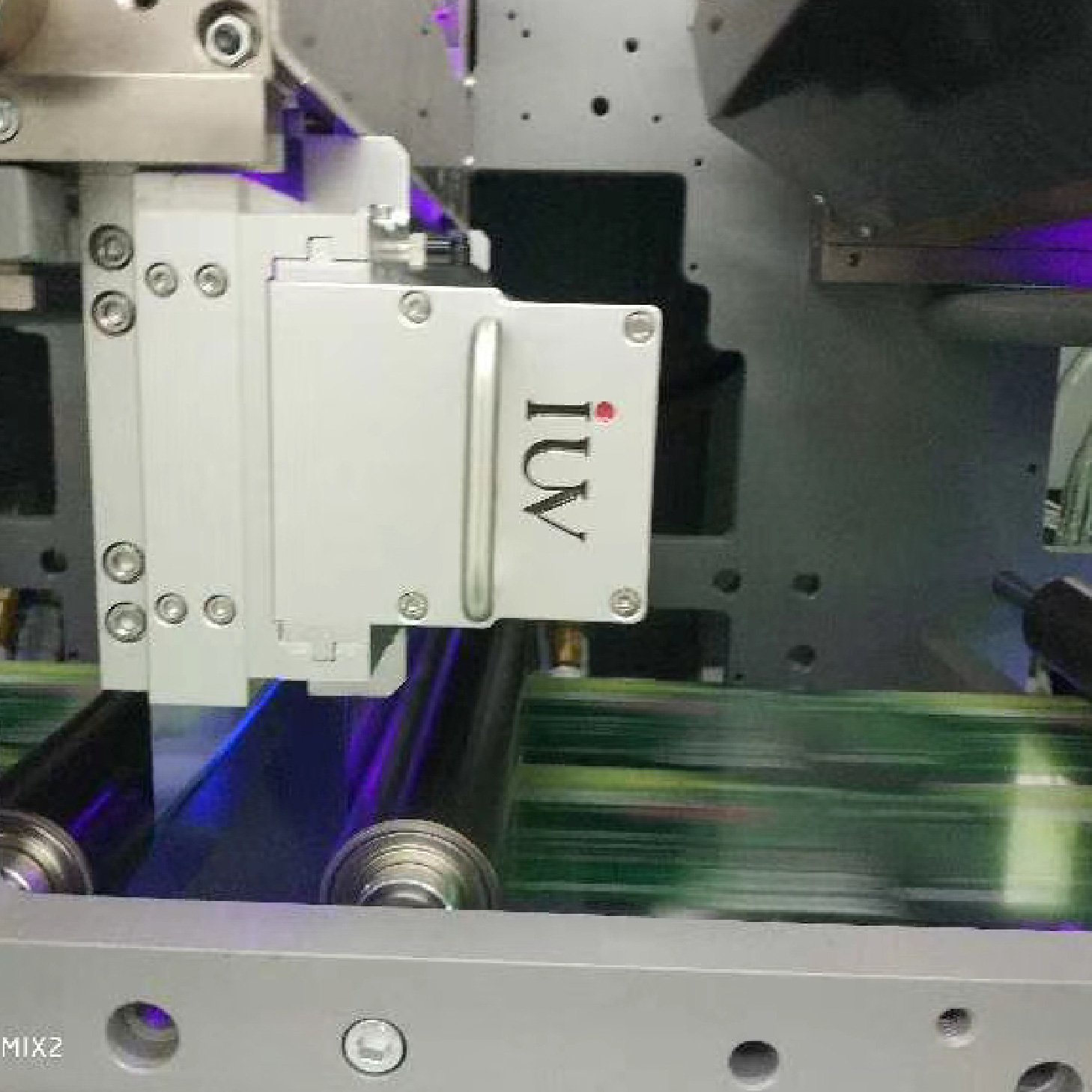

Enter LED UV curing technology. Light Emitting Diodes (LEDs) offer a fundamentally different approach. Instead of a broad spectrum, LEDs emit UV light at specific wavelengths. This targeted output is more efficient. It allows for precise control over the curing process. LED systems are also highly energy-efficient. They consume significantly less power than mercury lamps.

One of the most significant advantages of LED UV curing is its low heat output. This is a game-changer for narrow web printers. It opens up possibilities for printing on a wider range of heat-sensitive materials. Think of thin films, delicate papers, or even some plastics. The reduced heat means less chance of substrate distortion. This leads to sharper details and better registration, crucial for high-quality labels.

Another major benefit is the operational cost. LED lamps have a much longer lifespan than mercury lamps. We’re talking tens of thousands of hours, compared to a few thousand for mercury. This dramatically reduces lamp replacement frequency and associated costs. The energy savings are also substantial, contributing to lower overall operating expenses.

LED UV curing systems also offer faster start-up and shut-down times. They reach full curing power almost instantaneously. This minimizes waste during job changes. It also allows for quicker press restarts. This boosts productivity and throughput. The environmental benefits are also noteworthy. LED systems are mercury-free. They eliminate the need for special disposal procedures.

When considering narrow web printing applications like labels, flexible packaging, and specialty printing, the choice often hinges on specific needs. For high-speed, demanding applications requiring the utmost in print quality and substrate versatility, LED UV curing is increasingly the preferred option. Its efficiency, low heat, and long lamp life translate to tangible benefits in both operational cost and end-product quality.

Traditional UV curing systems, while still viable, may be better suited for older presses where retrofitting might be complex or for applications where substrate heat is not a major concern. However, the trend is undeniably towards LED technology. Manufacturers are investing heavily in refining LED curing solutions. This includes developing new ink formulations optimized for specific LED wavelengths.

The integration of LED UV curing into flexographic and offset printing presses for narrow web applications is transforming the industry. For label printers, this means the ability to produce vibrant, durable labels on a wider array of materials. For flexible packaging converters, it allows for faster production runs and enhanced product appeal.

The initial investment for an LED UV curing system can sometimes be higher than for a traditional UV system. However, the long-term savings in energy consumption, lamp replacement, and reduced waste often make it a more cost-effective solution over the lifespan of the equipment. When evaluating ROI, it’s essential to consider all these factors.

The precise wavelength output of LEDs also allows for more consistent curing. This consistency is vital for achieving repeatable results. It ensures that every print batch meets the same high standards. This is particularly important for brand owners who rely on consistent product presentation.

In summary, while traditional UV curing has served the industry well, LED UV curing represents a significant technological advancement. For narrow web printers focused on efficiency, versatility, and long-term cost savings, the advantages of LED technology are compelling. It’s a powerful tool for staying competitive in today’s fast-paced printing market.