UV curing is transforming commercial offset printing. This technology offers significant advantages. It speeds up production. It improves print quality. It also expands the range of printable materials. For many printers, it’s becoming an indispensable tool.

LED UV curing, in particular, is gaining traction. It’s more energy-efficient than traditional mercury lamps. It also has a longer lifespan. This makes it a cost-effective choice for businesses.

In commercial offset printing, UV curing involves using ultraviolet light. This light initiates a photochemical process. It instantly dries or cures inks, coatings, and adhesives. The ink contains monomers and oligomers. When exposed to UV light, these molecules link together. They form a solid, durable film. This process happens in seconds.

This rapid drying is a major benefit. It means sheets can be handled immediately. There’s no waiting for ink to dry. This dramatically increases press speed. It reduces turnaround times for jobs. Printers can take on more work. They can meet tighter deadlines.

The quality of prints produced with UV curing is often superior. UV inks and coatings provide excellent gloss and vibrant colors. The instant drying prevents ink from soaking into the paper. This results in sharper images and crisper text. The cured ink film is also very durable. It resists scuffing, scratching, and fading. This is crucial for packaging and labels.

UV curing is versatile. It works on a wide array of substrates. This includes coated and uncoated papers. It also cures on plastics, vinyl, and even metals. This opens up new markets for commercial printers. They can print on materials previously unsuitable for offset. This flexibility is a significant competitive advantage.

In narrow web printing, UV curing is already a standard. Label printers rely heavily on it. The high speeds of narrow web presses demand fast drying. UV inks cure instantly, allowing for immediate finishing. This includes slitting, rewinding, and die-cutting. The durability of UV-cured inks is also perfect for labels. Labels often face harsh conditions. They need to resist abrasion and chemicals.

Flexographic printing, often used for packaging and labels, also benefits immensely from UV curing. UV flexo inks provide excellent adhesion on non-porous substrates. Think about films and foils. These materials are common in flexible packaging. The ability to cure instantly on these surfaces is a game-changer. It allows for high-speed production runs. It ensures consistent print quality across the entire job.

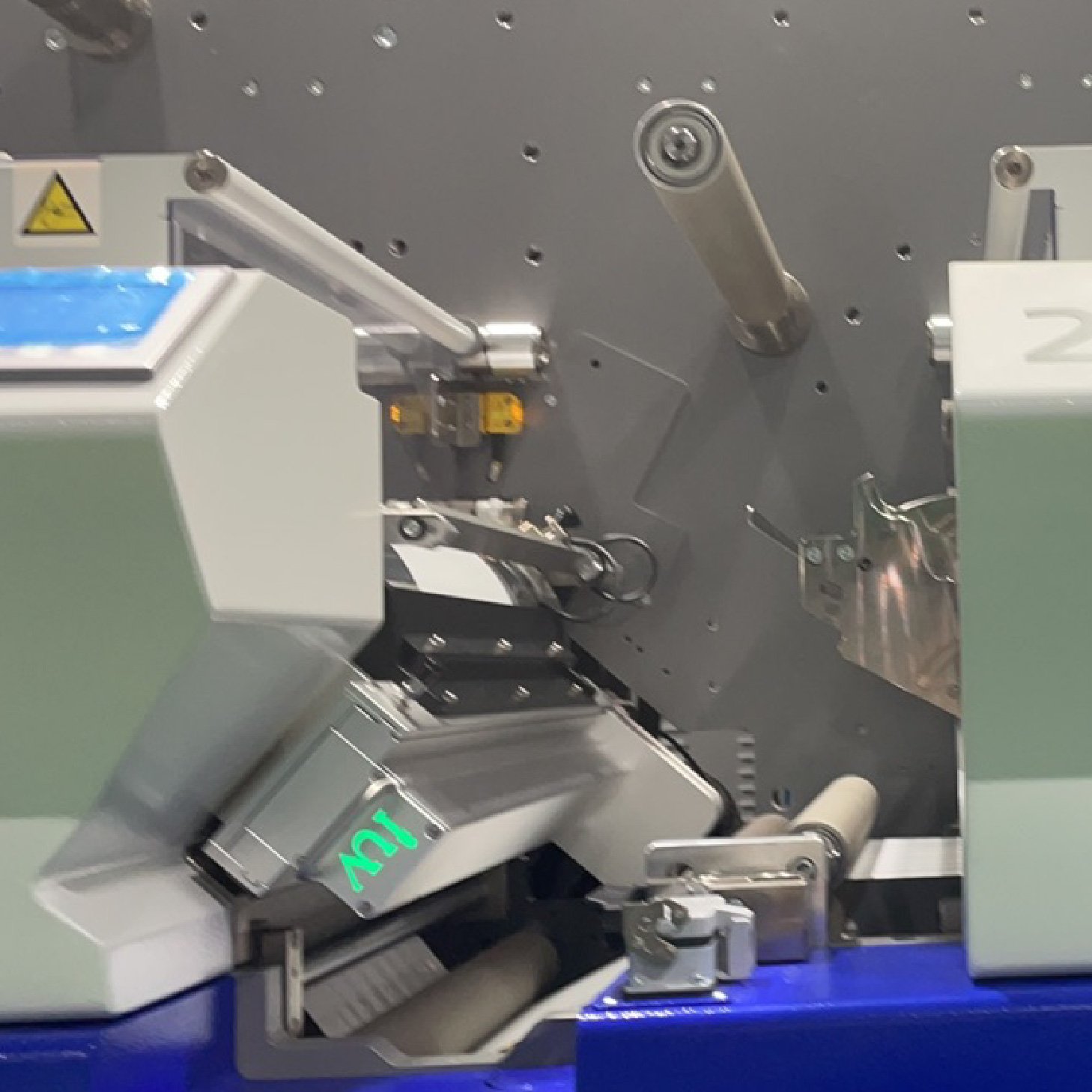

Offset printing, or lithographic printing, is also embracing UV technology. Sheetfed offset presses can be retrofitted with UV curing units. This allows printers to offer high-quality, durable prints. They can achieve special effects with UV coatings. Think about spot gloss or matte finishes. These add visual appeal to brochures, flyers, and marketing materials.

However, there are challenges to consider with UV curing systems. One significant challenge is the initial investment. UV curing equipment can be expensive. This includes the lamps themselves, the power supplies, and the necessary ventilation. For smaller print shops, this upfront cost can be a barrier.

Another consideration is energy consumption. While LED UV is more efficient, traditional UV lamps can consume a lot of power. This can increase operational costs. Proper maintenance of the curing units is also essential. Lamps have a finite lifespan. They need to be replaced periodically.

Ink and coating compatibility is also important. Not all inks and coatings are designed for UV curing. Printers must use specific UV-curable formulations. These can sometimes be more expensive than conventional inks. It’s vital to select the right products for the job.

Ventilation is another crucial aspect. UV curing releases ozone. This is a byproduct of the UV light interacting with air. Proper ventilation systems are required to remove ozone safely. This ensures a healthy working environment for press operators.

Substrate sensitivity can also be a challenge. Some heat-sensitive substrates can be damaged by the heat generated by UV lamps. While LED UV systems run cooler than traditional mercury lamps, careful consideration of the substrate is still necessary. Testing is often recommended before running large jobs.

The learning curve for operating UV curing systems can also be a factor. Press operators need to understand the specific requirements of UV inks and equipment. This includes proper curing parameters. They need to know how to troubleshoot issues. Training is important to ensure optimal performance.

Despite these challenges, the benefits of UV curing in commercial offset printing are compelling. The speed, quality, and versatility it offers are hard to ignore. As the technology continues to evolve, particularly with LED UV, it becomes more accessible and efficient.

For businesses looking to enhance their printing capabilities, UV curing is a technology worth exploring. It can lead to increased productivity. It can improve product appeal. It can open doors to new printing applications. The future of commercial offset printing is undoubtedly brighter with UV technology. It’s about achieving faster, better, and more durable printed products. This technology helps meet the demands of today’s market.