UV Curing Systems for Packaging: Enhancing Quality and Efficiency

The packaging industry is constantly seeking ways to improve print quality and production speed. UV curing systems offer a powerful solution. These systems use ultraviolet light to instantly dry inks and coatings. This process is faster and more efficient than traditional drying methods. For label printing and flexible packaging, UV technology is a game-changer.

Understanding UV Curing Technology

UV curing involves photochemical reactions. Special inks and coatings contain photoinitiators. When exposed to UV light, these photoinitiators absorb energy. This energy triggers a rapid polymerization process. The liquid ink or coating transforms into a solid, durable film almost instantaneously. This means prints are ready for the next stage of production immediately. There’s no waiting for drying.

Benefits for Label Printing

In narrow web label printing, speed and precision are paramount. UV curing excels in this environment. Labels often require vibrant colors and sharp details. UV inks achieve this with excellent color saturation. They also offer superior scratch and chemical resistance. This is vital for product labels that face harsh handling or environmental conditions. The instant drying capability of UV systems allows for higher press speeds. This directly translates to increased output and reduced production times. Furthermore, UV inks are environmentally friendly. They contain very few volatile organic compounds (VOCs). This aligns with growing demands for sustainable packaging solutions.

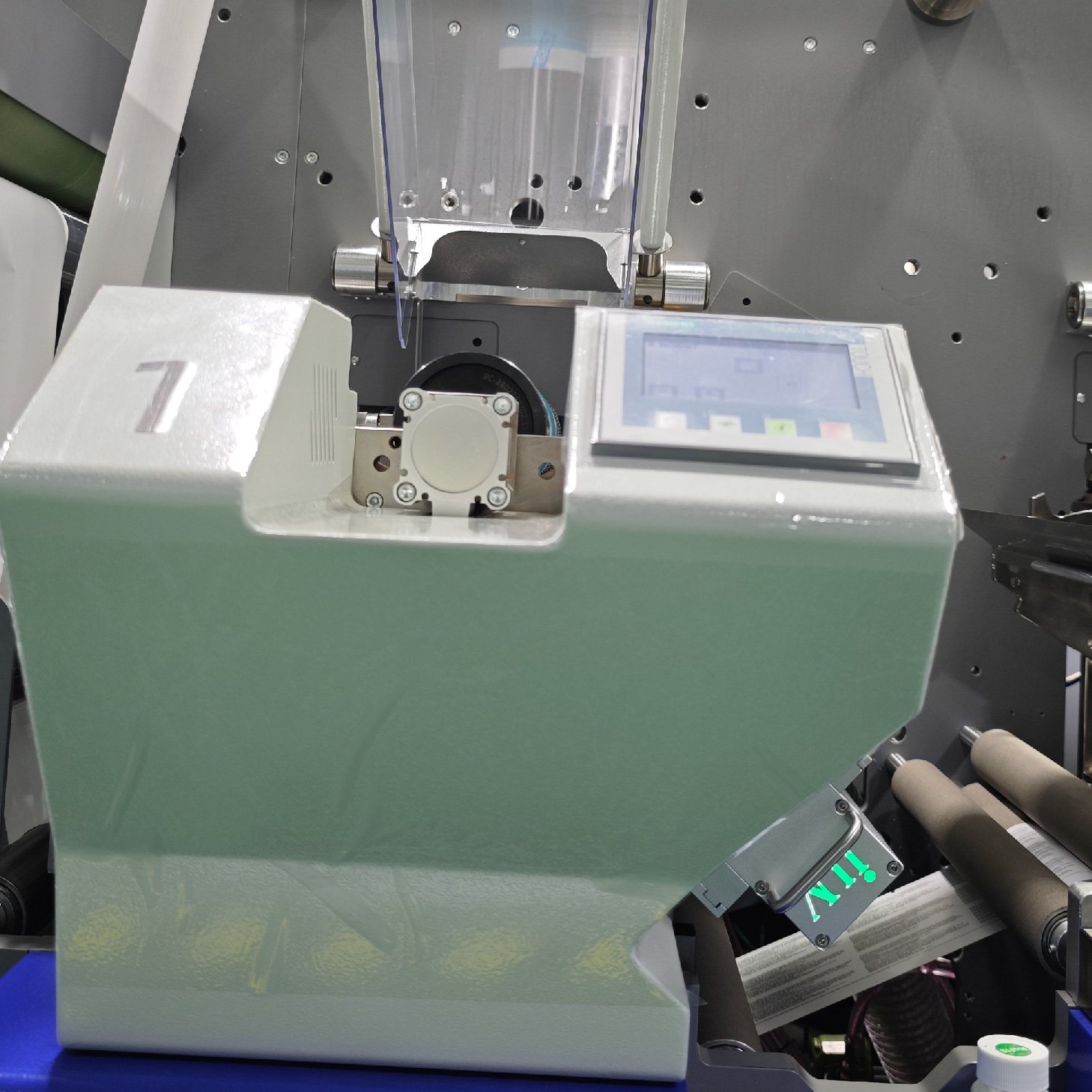

UV Curing in Flexographic Printing

Flexographic printing is a popular choice for packaging, especially for flexible films and labels. UV curing integrates seamlessly with flexo presses. It allows printers to achieve exceptional print quality on a wide range of substrates. This includes plastics, foils, and coated papers. The fast drying nature of UV inks prevents smudging and ink transfer issues. This is crucial when printing multiple colors in tight registration. The durability of UV-cured prints is another significant advantage. Packaging needs to withstand transport, storage, and consumer handling. UV coatings provide a protective barrier against abrasion and fading. This ensures the brand’s message remains intact from production to point of sale.

Offset Printing and UV Curing

While traditionally associated with different drying methods, offset printing also benefits immensely from UV technology. For packaging applications, UV offset printing offers high-quality graphics and consistent color reproduction. This is especially true for folding cartons and high-end labels. The ability of UV inks to cure on non-absorbent substrates like plastics and metalized papers is a key advantage for offset. This opens up new design possibilities for packaging. The instant curing eliminates the need for inter-station drying equipment. This saves valuable space on the press and simplifies the printing process. The enhanced durability and resistance properties of UV-cured offset prints further solidify its appeal in the packaging sector.

LED UV Curing: The Next Generation

A significant advancement in UV curing is the adoption of LED technology. Traditional UV curing uses mercury lamps. These lamps consume a lot of energy and generate considerable heat. They also have a limited lifespan and require frequent replacement. LED UV systems, on the other hand, are much more energy-efficient. They consume significantly less power and produce almost no heat. This is a major benefit when printing on heat-sensitive materials. LED lamps also have a much longer operational life, reducing maintenance costs and downtime. They are instant on/off, which is beneficial for job changes and reduces energy waste. The spectral output of LEDs can be precisely controlled. This allows for optimized curing of specific ink formulations. This precision can lead to even better print quality and ink performance.

Enhancing Efficiency and Productivity

The speed of UV curing directly boosts production efficiency. Faster drying means faster turnaround times for print jobs. This allows packaging converters to meet tighter deadlines and accept more orders. The reduced need for lengthy drying processes also leads to higher press uptime. Printers can move from one job to the next more quickly. The durability of UV-cured prints also contributes to efficiency. Fewer reprints due to defects or handling damage mean less waste and lower costs. The environmental benefits of UV curing, particularly low VOC emissions, also contribute to operational efficiency by helping companies meet regulatory requirements.

Improving Print Quality and Durability

UV curing systems are instrumental in achieving superior print quality. They enable sharper dots, finer details, and more vibrant colors compared to conventional methods. The instant solidification of the ink prevents it from spreading or bleeding into the substrate. This maintains the integrity of the design. The protective nature of UV-cured inks and coatings is also a significant quality enhancement. They provide excellent resistance to scuffing, scratching, chemicals, and fading. This ensures that the packaging looks good and performs well throughout its lifecycle. This enhanced durability protects the printed graphics and the product within.

Choosing the Right UV Curing System

Selecting the appropriate UV curing system depends on several factors. Consider the type of printing press being used (narrow web, flexo, offset). Also, evaluate the substrates you typically print on. The specific inks and coatings you intend to use are crucial. The desired production speed and any special finishing requirements should also guide your decision. For new installations or upgrades, LED UV systems are increasingly becoming the preferred choice due to their efficiency, longevity, and environmental advantages. Consulting with equipment manufacturers and ink suppliers is advisable to ensure optimal integration and performance.

The Future of Packaging with UV Curing

UV curing technology continues to evolve. Innovations in UV-LED systems and new ink formulations are constantly emerging. These advancements promise even greater efficiency, higher quality, and broader application possibilities. As the demand for visually appealing, durable, and sustainably produced packaging grows, UV curing systems will play an even more critical role. They are an essential tool for printers looking to stay competitive in the dynamic packaging market. Embracing UV curing is a strategic move towards a more productive, high-quality, and sustainable future in packaging printing.