UV curing systems are revolutionizing industrial printing. They offer incredible benefits for durability and print quality. This technology is a game-changer for various printing methods. Let’s explore how UV curing enhances labels, flexo, offset, and narrow web printing.

The Power of UV Curing in Printing

UV curing utilizes ultraviolet light. This light initiates a photochemical process. It rapidly cures or hardens inks, coatings, and adhesives. The process is almost instantaneous. This speed is a major advantage in modern printing. It dramatically increases production efficiency.

UV curable inks contain monomers and oligomers. They also have photoinitiators. When exposed to UV light, photoinitiators absorb energy. This energy starts a chain reaction. The monomers and oligomers link together. This forms a solid, cross-linked polymer. The result is a highly durable, scratch-resistant print.

Benefits for Label Printing

Label printing demands high quality and robustness. Labels are often exposed to harsh environments. They can face abrasion, chemicals, and moisture. UV curing provides the perfect solution.

UV inks create a tough, resilient ink layer. This enhances scratch and scuff resistance significantly. For food and beverage labels, this is critical. They need to withstand handling and potential spills. UV coatings can also add a high-gloss finish. This makes labels visually appealing. It also protects the printed graphics underneath.

Narrow web printing, commonly used for labels, benefits greatly. The fast curing speed allows for high-speed presses. This translates to higher output and lower per-unit costs. Printing on a variety of substrates is also easier with UV. Plastics, films, and foils can all be successfully printed. UV inks adhere well to these non-porous surfaces.

Enhancing Flexographic Printing

Flexographic printing is widely used for packaging and labels. It uses flexible relief plates. UV curing integrates seamlessly with flexo processes.

In flexography, precise ink transfer is key. UV inks, when cured quickly, maintain sharp dot definition. This leads to crisper images and text. The rapid cure prevents ink spread. This is especially important for fine details and fine screens.

UV technology in flexo also allows for thicker ink laydowns. This can result in richer colors and better opacity. Many flexo presses now come equipped with UV curing units. This upgrade boosts their performance and versatility. Printers can achieve better color gamut and consistency. They can also improve the tactile feel of the print.

Advantages in Offset Lithography

Offset printing is known for its high print quality. It’s often used for commercial printing and high-end packaging. UV curing offers substantial improvements here too.

Traditional offset inks can take time to dry. This can slow down post-press processes. UV offset inks cure instantly under UV light. This eliminates the need for drying racks. Printed sheets can be moved immediately to finishing. This significantly reduces turnaround times.

UV curing in offset also enhances durability. The cured ink is highly resistant to smudging and scratching. This is valuable for printed materials that undergo frequent handling. Think of book covers, brochures, or high-quality packaging. UV coatings can also add special effects. These include matte finishes, soft-touch textures, or spot varnishes.

Narrow Web Printing and the UV Advantage

Narrow web printing focuses on producing narrow-width rolls. This is ideal for labels, flexible packaging, and specialty printing. UV curing is almost standard in this sector.

The high speeds of narrow web presses demand fast drying. UV curing is the perfect match. It enables presses to run at their maximum speed. This maximizes productivity.

UV inks and coatings offer excellent adhesion on various narrow web substrates. These include films, foils, and laminates. The cured print is robust. It can withstand the stresses of die-cutting and rewinding. This reduces waste and improves product quality.

Furthermore, LED UV curing is gaining prominence. LED UV lamps offer several advantages over traditional mercury lamps. They consume less energy. They produce less heat. They have a much longer lifespan. This reduces operational costs and environmental impact. LED UV curing also provides a more consistent UV output. This ensures reliable curing across the entire print run.

Achieving Superior Durability and Quality

The primary goal of UV curing is enhanced durability and quality. Let’s summarize how it achieves this across different printing types.

- Scratch and Abrasion Resistance: UV inks form a hard, cross-linked surface. This protects the print from physical damage. This is crucial for labels and packaging.

- Chemical Resistance: The cured polymer is less susceptible to solvents and chemicals. This is important for industrial labels and packaging exposed to cleaning agents or products.

- Color Vibrancy and Sharpness: Instant curing locks in fine details. This results in vibrant colors and sharp text. Dot gain is minimized.

- Substrate Versatility: UV inks adhere well to a wide range of materials. This includes plastics, films, foils, and coated papers. This opens up possibilities for unique packaging and labels.

- Reduced VOC Emissions: UV curable inks typically have very low or no volatile organic compounds (VOCs). This makes them an environmentally friendlier option.

- Faster Production Speeds: The instantaneous curing allows for faster press speeds and immediate post-press handling. This cuts down production cycles and increases throughput.

Choosing the Right UV Curing System

When selecting a UV curing system, several factors are important. The type of printing press is a key consideration. The speed of the press will dictate the required UV power. The type of inks and coatings being used also matters. Different formulations require specific UV wavelengths and intensities.

Substrate properties are another factor. Some materials may be sensitive to heat. In such cases, LED UV curing is preferable due to its lower heat output. The desired level of durability and finish will also influence the choice of system.

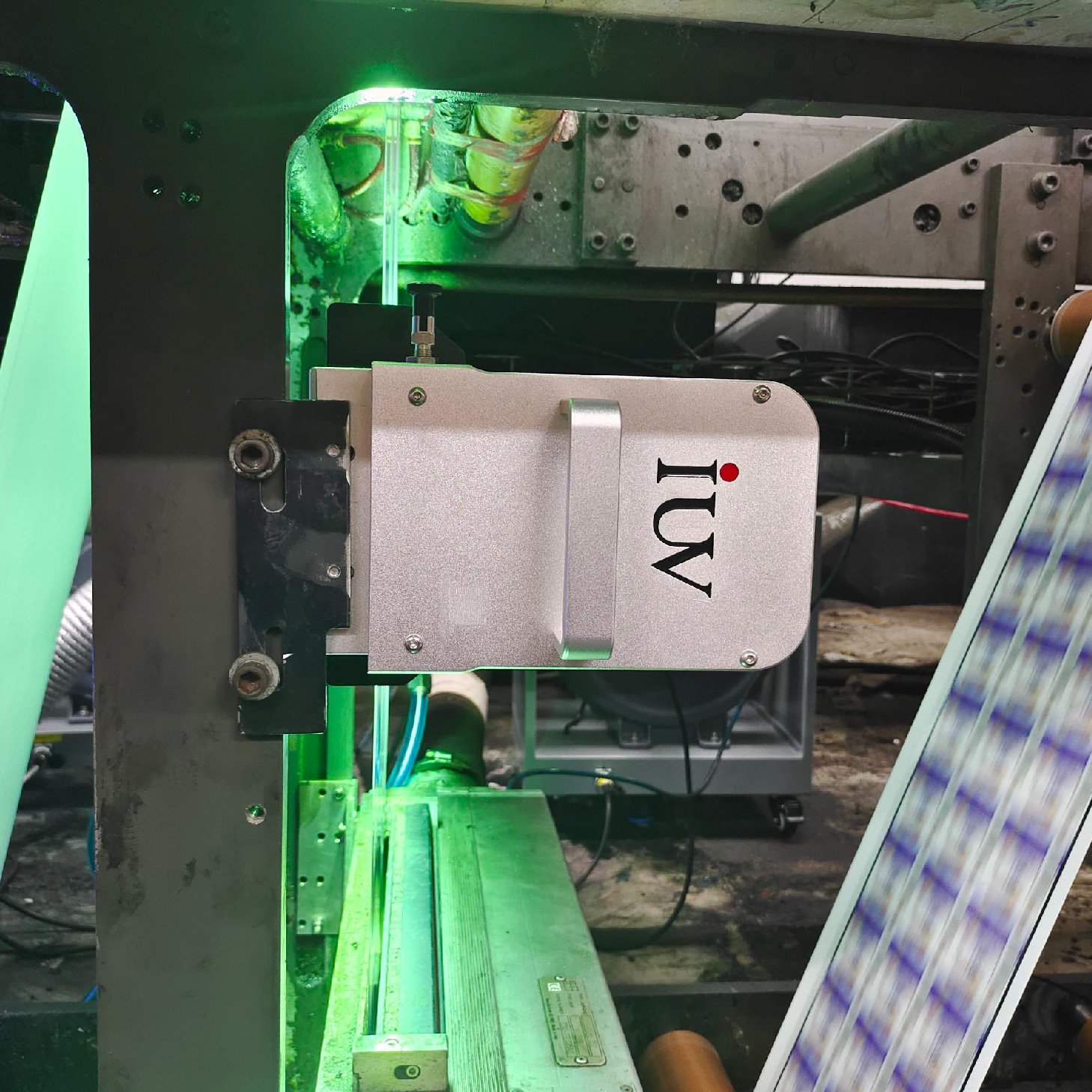

Modern UV curing systems are highly adaptable. They can be integrated into new presses or retrofitted onto existing equipment. Understanding the specific application needs is paramount. This ensures optimal performance and maximum return on investment.

In conclusion, UV curing systems offer undeniable advantages. They enhance durability, improve print quality, and boost efficiency. For label, flexographic, offset, and narrow web printing, they represent a significant technological leap. Embracing this technology allows printers to meet the demanding requirements of today’s market. They can deliver superior products consistently and competitively.