UV Curing Flexo Printing for Small Batch Production: Quality Meets Efficiency

Small batch production is a dynamic landscape. Businesses today need flexibility and speed. They also demand high-quality printed materials. Labels are a prime example. The demand for custom labels in short runs is surging. Think craft beverages, specialty foods, and promotional items. Traditional printing methods often struggle with these requirements. They can be slow and costly for limited runs. This is where UV curing flexo printing truly shines. It offers a powerful combination of quality and efficiency.

Flexographic printing, or flexo, is a versatile printing process. It uses a flexible relief plate. Ink is transferred from the plate to the substrate. This method is known for its speed and ability to print on a wide range of materials. These include plastics, films, and paper. For small batch runs, flexo’s adaptability is a significant advantage. It allows for quick setup and changeovers. This minimizes downtime between different jobs.

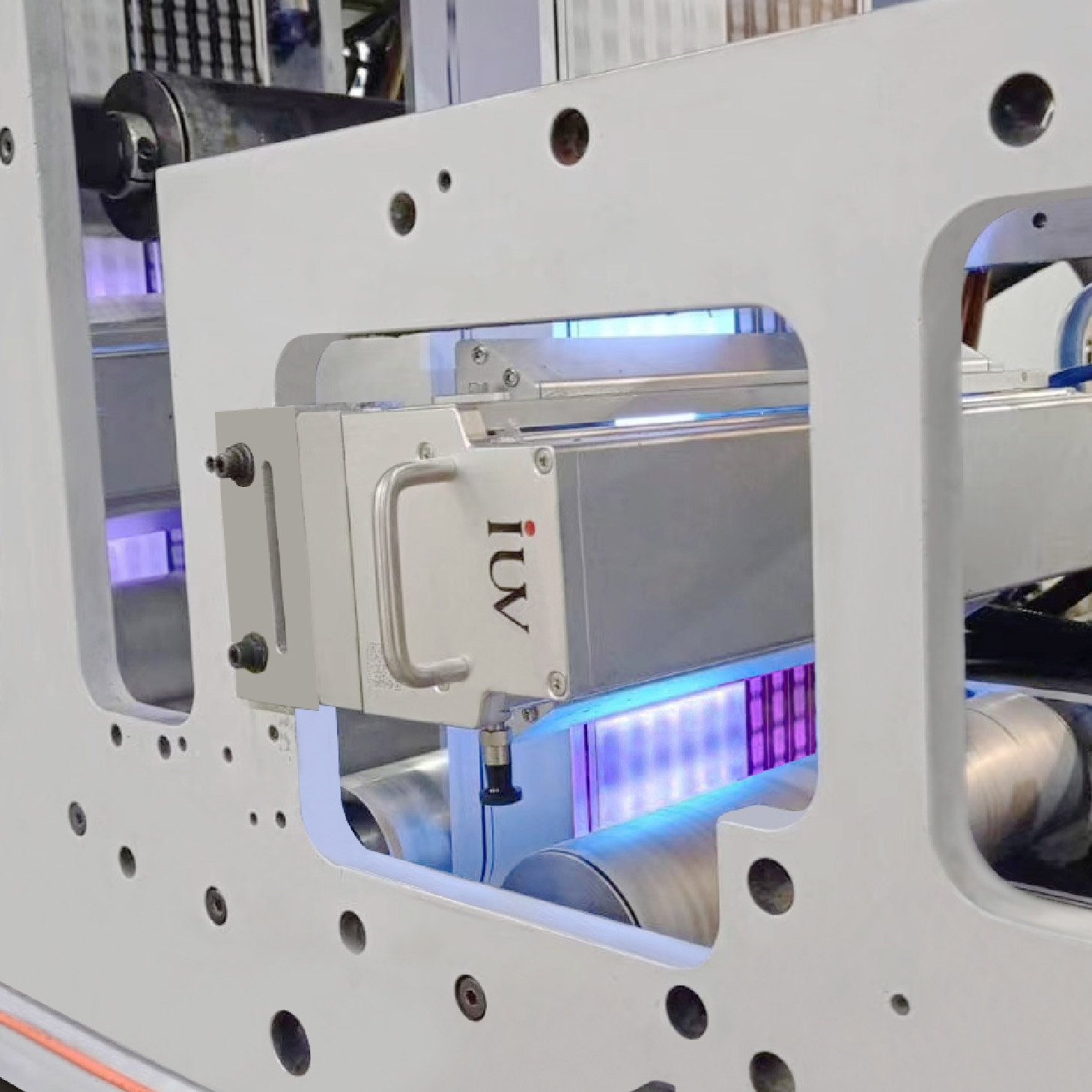

The real game-changer for small batch flexo printing is UV curing technology. Traditional inks require drying time. This can slow down the printing process. UV curable inks, however, dry instantly. They do this when exposed to ultraviolet light. This is where LED UV curing comes in. LED UV lamps offer a more energy-efficient and sustainable alternative. They provide precise control over the curing spectrum. This ensures optimal ink performance.

The integration of LED UV curing with flexo printing addresses several key challenges for small batch production. Firstly, there is the issue of speed. Instant curing means printed labels can be immediately handled, cut, or finished. There’s no waiting for inks to dry. This drastically reduces production cycles. For businesses needing rapid turnaround on small orders, this is invaluable. It translates directly into getting products to market faster.

Secondly, quality is paramount. UV curable inks offer exceptional print quality. They provide vibrant colors. They also deliver sharp details and excellent adhesion. This is true even on challenging substrates like films and foils. The precision of flexo printing, combined with the robustness of UV inks, results in labels that look professional and durable. Even for a small batch, the finished product must meet high standards. UV flexo ensures this.

Thirdly, efficiency extends to material usage and waste reduction. The quick setup times in flexo mean less material is wasted during makeready. This is especially beneficial for short runs where makeready waste can represent a significant percentage of the total print volume. Furthermore, the immediate curing of UV inks prevents smudging or offsetting. This reduces the likelihood of spoiled prints.

For label printers, offering small batch production capabilities is becoming essential. Customers are increasingly seeking customized solutions. They want labels that reflect their brand identity and product uniqueness. UV curing flexo printing allows printers to cater to this demand cost-effectively. They can produce short runs without compromising on quality or profitability. This opens up new market opportunities. It also helps retain existing customers who require flexibility.

When we talk about narrow web printing, flexo is often the go-to technology. Narrow web presses are designed for printing on narrow rolls of material. This is ideal for labels and flexible packaging. Incorporating LED UV curing into these presses further enhances their suitability for small batch work. The compact nature of LED UV lamps allows them to be easily integrated into existing narrow web lines. They require less power than traditional UV lamps. They also have a much longer lifespan.

The print quality from a well-configured UV flexo press is impressive. Expect high line screens for fine text and detailed graphics. Expect consistent color density across the entire run, no matter how short. The inks are resistant to abrasion, chemicals, and fading. This makes them suitable for demanding applications. Think product labels exposed to harsh environments or frequent handling.

Consider the transition from offset printing for certain applications. Offset printing is excellent for high-volume, high-quality commercial printing. However, for narrow web labels and short runs, it can be less economical. The plate costs and setup times for offset can be prohibitive for small batches. Flexo, with its inherent speed and lower plate costs, combined with the efficiency of UV curing, offers a compelling alternative. It bridges the gap between the quality of offset and the demands of flexible, short-run production.

The operational benefits of LED UV curing are also noteworthy. Unlike mercury vapor UV lamps, LED UV systems run cooler. This reduces the thermal stress on the substrate. This is particularly important when printing on heat-sensitive materials. It also contributes to a safer working environment. The instant on/off nature of LEDs means they only consume energy when the press is running. This leads to significant energy savings compared to continuously running mercury lamps.

Implementing UV curing flexo for small batches is not just about technology; it’s about a strategic advantage. It allows businesses to be more agile. They can respond quickly to market trends. They can offer personalized products. They can reduce lead times for customers. This can be a deciding factor in competitive markets. The ability to deliver high-quality, custom labels efficiently, even in small quantities, builds strong customer loyalty.

The future of label production is increasingly leaning towards shorter runs and greater customization. UV curing flexo printing, especially with advancements in LED technology, is perfectly positioned to meet these evolving needs. It offers a proven path to achieving both exceptional quality and operational efficiency in the challenging realm of small batch production. This makes it an indispensable tool for modern label printers looking to thrive.