Understanding Thermal Management in LED Curing Systems for Printing Applications

In modern printing, especially in narrow-web, label, and flexographic printing, UV curing technology plays a crucial role. The shift toward LED-based UV curing systems has revolutionized the industry, offering better energy efficiency, faster drying times, and more precise control over the curing process. However, with these advancements comes the need to understand the thermal management within these LED curing systems to ensure optimal performance. Effective thermal management is key to the longevity of the equipment, the quality of the final product, and overall system efficiency.

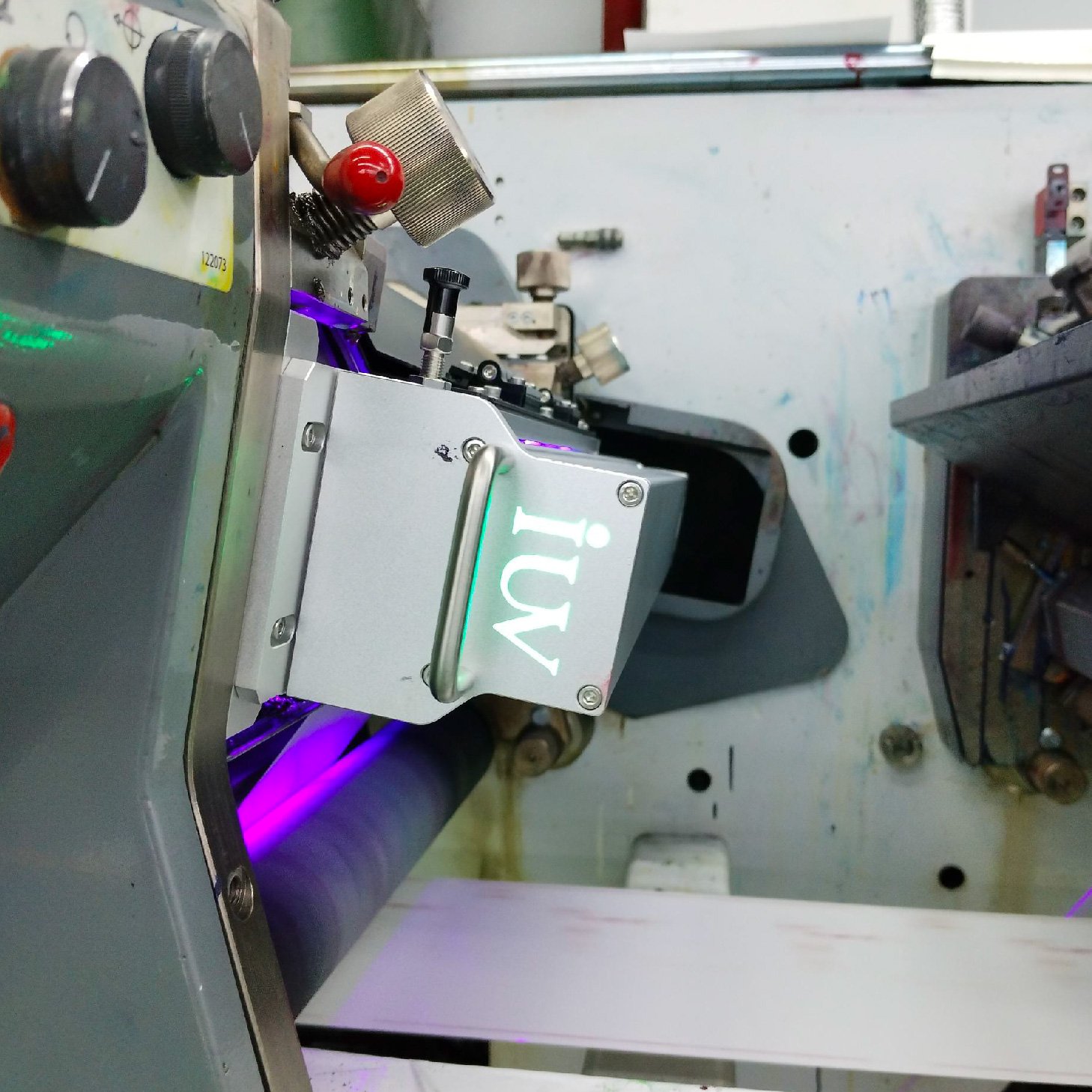

The Role of LED Curing Systems in Printing

LED UV curing systems utilize light-emitting diodes to emit UV light, which cures UV-sensitive inks or coatings instantly. Unlike traditional mercury vapor lamps, LED systems offer several advantages, such as lower energy consumption, reduced heat generation, and longer lifespans. These benefits make them a preferred choice in various printing applications, including narrow-web printing, label printing, and flexographic printing.

However, LED systems, despite their energy efficiency, generate heat, which needs to be managed effectively to prevent damage to sensitive components and ensure consistent performance. This is where thermal management becomes essential.

Why Thermal Management Matters

Thermal management refers to the process of controlling and dissipating heat produced by the LED curing system during operation. Poor heat management can lead to several issues, including:

- Reduced LED lifespan: Excessive heat can shorten the life of LEDs, leading to more frequent replacements and increased operational costs.

- Inconsistent curing: If the temperature of the curing system fluctuates too much, it can cause uneven curing of inks, which impacts the quality of the print.

- Component failure: Components such as power supplies, drivers, and optics are all sensitive to heat. Overheating can cause them to fail, resulting in costly repairs or replacements.

- Safety risks: Overheated systems can pose safety risks, such as electrical failures or even fires.

Therefore, managing the heat produced by the LED units is critical to maintaining consistent quality and ensuring the longevity of both the curing system and the printed materials.

Key Thermal Management Strategies

Several strategies are employed in the design and operation of LED UV curing systems to effectively manage thermal energy. These include:

1. Heat Sink and Cooling Technology

Heat sinks are essential in dissipating heat away from the LED modules. They are typically made of materials with high thermal conductivity, such as aluminum, to absorb and distribute heat. In some systems, active cooling mechanisms like fans or liquid cooling systems may also be integrated to ensure the temperature remains within optimal ranges. Cooling efficiency is crucial to preventing thermal buildup and maintaining a steady output from the LEDs.

2. Thermal Interface Materials (TIMs)

Thermal interface materials are used between the LED modules and heat sinks to improve heat transfer. TIMs help reduce the thermal resistance between surfaces, ensuring that the heat generated by the LED units is quickly conducted away. Common materials used for this purpose include thermal pastes, pads, and tapes. Selecting the right TIM is crucial for optimizing the thermal performance of the system.

3. Active Temperature Monitoring

Modern LED UV curing systems often include sensors to monitor the temperature of the LED array and surrounding components. These sensors allow operators to track temperature changes in real-time and adjust the cooling system accordingly. In some systems, automatic adjustments are made to prevent overheating, such as reducing the intensity of the LEDs or activating additional cooling.

4. Ambient Temperature Control

In some environments, ambient temperature can significantly affect the performance of an LED curing system. Maintaining a controlled room temperature helps ensure that the system operates within its designed thermal limits. Proper ventilation and air conditioning in the printing area can help keep the temperature within an ideal range, thus reducing the strain on the internal cooling mechanisms of the LED unit.

Managing Heat in Flexographic, Narrow-Web, and Label Printing

In flexographic printing, which is commonly used for packaging and labels, heat management is particularly critical. The high-speed operation of flexographic presses combined with the need for quick drying of inks makes it vital to maintain consistent curing. LED curing systems, due to their low heat output compared to traditional mercury vapor lamps, help prevent distortion or warping of substrates, which is a common issue with excessive heat.

For narrow-web printing and label printing, where high-quality, precise curing is required, effective thermal management ensures that the ink layers are cured evenly without under or over curing. This results in vibrant colors and sharp details, which are essential for high-quality prints.

In all of these applications, the use of LED curing systems is paired with sophisticated thermal management techniques to ensure that heat is effectively dissipated, allowing for smooth and efficient production runs.

Challenges in Thermal Management

Although LED UV curing systems have advanced thermal management capabilities, several challenges remain. One of the primary challenges is the heat buildup in high-output systems, which are used for faster print speeds or higher power output. As the intensity of the LED light increases, so does the heat produced. Overcoming this challenge requires more advanced cooling systems and careful design of the curing system components to handle the increased thermal load.

Another challenge is the potential for uneven heat distribution. If the heat is not distributed evenly across the LED array, certain areas may overheat while others remain undercooled. This can lead to uneven curing and poor print quality. Manufacturers of LED curing systems are continually working to improve the design of these systems to ensure better thermal uniformity.

Conclusion

Effective thermal management is critical for the successful operation of LED UV curing systems in modern printing processes. By employing advanced cooling technologies, using high-quality thermal interface materials, and closely monitoring the system’s temperature, manufacturers can ensure the longevity and efficiency of their equipment while delivering high-quality prints. Whether in flexographic, narrow-web, or label printing, managing the heat generated by LED curing systems is essential to achieving consistent curing results and maintaining operational efficiency. As the printing industry continues to evolve, understanding and implementing effective thermal management strategies will remain a key factor in achieving optimal performance and reliability.