LED UV Curing Systems are rapidly transforming the printing industry, offering significant environmental benefits alongside improved print quality and operational efficiency. As the demand for eco-friendly solutions in manufacturing grows, the printing sector is increasingly adopting LED UV curing technologies to reduce environmental impact. This article will explore the environmental advantages of LED UV curing systems in the context of flexographic printing, narrow-web printing, and plate printing.

What Is LED UV Curing?

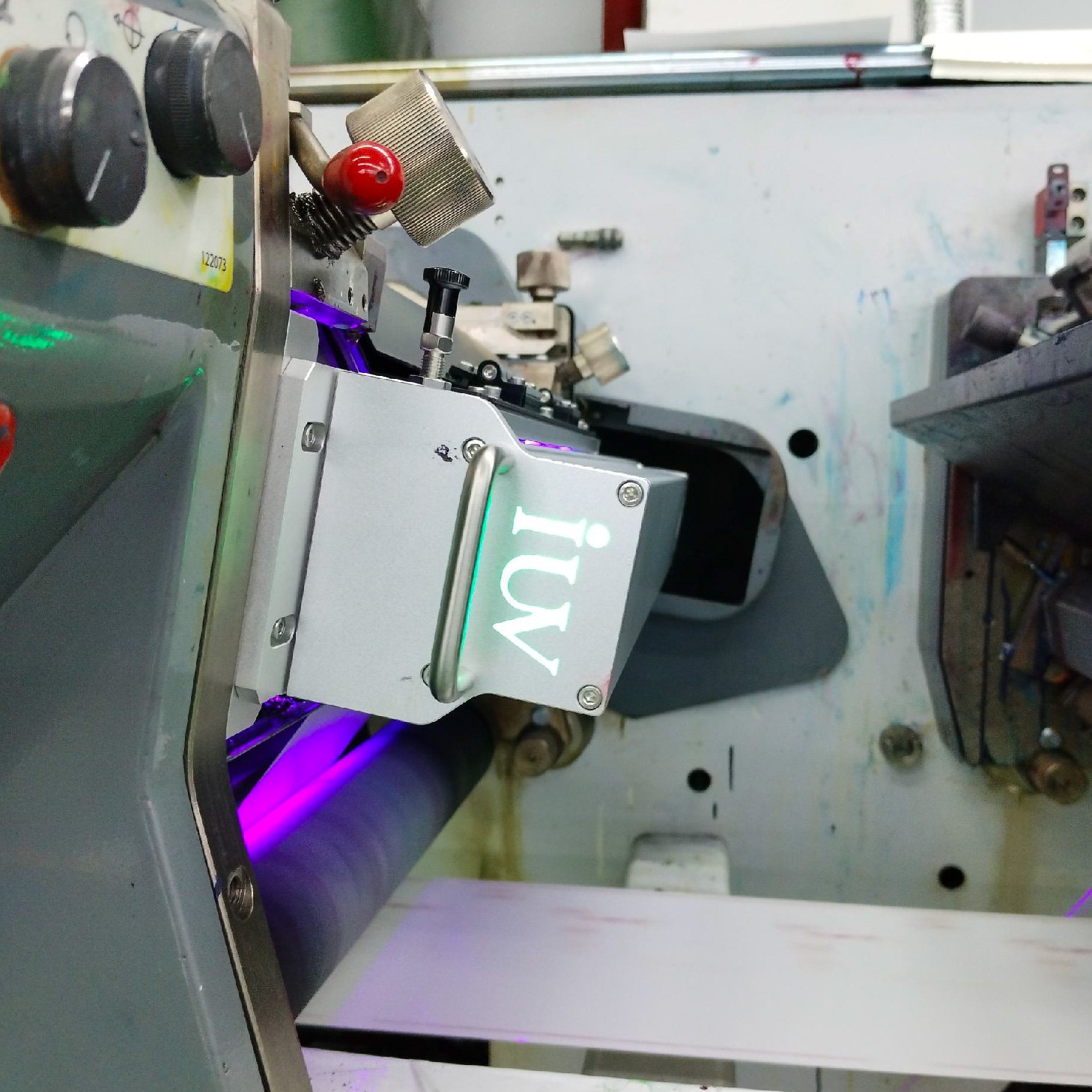

LED UV curing refers to the process where ultraviolet (UV) light is used to quickly cure or dry inks and coatings in printing applications. Unlike traditional UV curing, which uses mercury vapor lamps, LED UV curing utilizes light-emitting diodes (LEDs) to produce UV light. This process offers several environmental benefits that traditional curing methods cannot match, including lower energy consumption, reduced heat generation, and fewer harmful emissions.

Environmental Benefits of LED UV Curing in Printing

1. Energy Efficiency

One of the most significant advantages of LED UV curing systems is their energy efficiency. LED lamps consume considerably less energy than their mercury-based counterparts. While traditional UV lamps can require large amounts of energy to produce sufficient UV light, LED lamps use only a fraction of this energy. This reduced energy consumption directly lowers the carbon footprint of printing operations, contributing to more sustainable manufacturing processes.

In addition, LED UV lamps are instant-on, meaning they do not need to warm up before they start emitting light. This efficiency leads to further energy savings as printers can operate more effectively and with less downtime.

2. Reduced Heat Emissions

LED UV systems generate much less heat compared to conventional UV lamps. Traditional UV curing systems often require complex cooling systems to prevent overheating, which leads to increased energy consumption. In contrast, the low heat output of LED UV lamps reduces the need for additional cooling, making them more energy-efficient and environmentally friendly. This feature is particularly beneficial for printing operations that deal with heat-sensitive substrates, as it prevents warping or damage to materials.

3. Longer Lamp Life

LED UV lamps have a significantly longer lifespan than traditional mercury vapor lamps. Typically, an LED UV lamp can last up to 20,000 hours, while mercury lamps typically last around 1,000 hours. The extended lifespan of LED UV lamps reduces the need for frequent replacements, lowering both material waste and the environmental impact associated with the disposal of used lamps.

Furthermore, LED UV lamps do not contain hazardous materials like mercury, which is present in traditional UV lamps. The absence of mercury reduces the environmental hazards associated with lamp disposal and lowers the potential for toxic exposure in case of breakage.

4. Lower Emissions of Volatile Organic Compounds (VOCs)

In conventional printing processes, the curing of inks and coatings can lead to the release of volatile organic compounds (VOCs) into the air. These compounds are harmful to both the environment and human health. LED UV curing systems, however, produce significantly fewer VOCs because they cure inks faster and at lower temperatures, which minimizes the evaporation of harmful solvents during the process.

This reduction in VOC emissions is particularly important for industries that are under increasing regulatory pressure to minimize air pollution and adhere to environmental standards. By adopting LED UV curing technology, printing companies can ensure that they meet stringent environmental regulations while also reducing their overall environmental footprint.

5. Sustainability of Inks and Coatings

LED UV curing enables the use of eco-friendly inks and coatings. The fast curing process prevents the degradation of these materials and helps maintain their high quality. Many LED UV inks are formulated to be low in volatile solvents, further enhancing the sustainability of the printing process. As a result, businesses can reduce their reliance on harmful chemicals, contributing to the protection of both the environment and the health of workers.

Moreover, LED UV curing promotes the use of energy-efficient, solvent-free, and low-migration inks. These inks do not release harmful substances into the air or water, making them safer for the environment. The use of such inks is particularly beneficial for food packaging, where the safety of the printed materials is paramount.

Applications in Printing

LED UV curing systems are used in various printing applications, including flexographic printing, narrow-web printing, and plate printing. Each of these processes can benefit from the environmental advantages offered by LED UV curing technology.

1. Flexographic Printing

Flexographic printing is widely used for packaging and labels. The environmental benefits of LED UV curing in flexo printing include lower energy consumption, fewer emissions, and faster production times. Flexographic printers can print with eco-friendly inks that cure quickly under LED UV light, helping manufacturers reduce waste and improve overall efficiency.

2. Narrow-Web Printing

Narrow-web printing, commonly used for labels, flexible packaging, and other small-scale print jobs, is particularly well-suited to LED UV curing. The ability to cure inks instantly helps printers achieve high-quality, durable prints while minimizing energy consumption and waste. With the growing demand for sustainable packaging solutions, narrow-web printers are increasingly adopting LED UV technology to meet customer expectations for eco-friendly products.

3. Plate Printing

Plate printing, used in both offset and flexographic processes, also benefits from LED UV curing. The reduced heat output of LED lamps helps protect the integrity of plates, which can be sensitive to high temperatures. This allows for faster print runs and better color consistency, all while reducing the environmental impact of the printing process.

Conclusion

LED UV curing systems offer significant environmental advantages over traditional UV curing methods. From energy savings to reduced emissions and the use of eco-friendly inks, the shift toward LED UV curing technology is helping the printing industry reduce its carbon footprint while improving print quality and operational efficiency.

As sustainability becomes increasingly important to consumers and regulatory bodies, printing companies are adopting LED UV curing to meet growing environmental demands. Whether used in flexographic, narrow-web, or plate printing, LED UV curing is proving to be a game-changer for reducing energy consumption, lowering emissions, and minimizing waste.

By embracing LED UV curing technology, the printing industry is making great strides toward a more sustainable and eco-friendly future, benefiting both businesses and the planet.