In the dynamic world of modern printing, achieving efficient and consistent curing is paramount. LED UV curing systems have revolutionized this process, offering benefits like reduced energy consumption, faster speeds, and improved print quality. However, the effectiveness of these systems hinges critically on two interconnected design elements: cooling and optics. Neglecting either can lead to suboptimal performance, reduced equipment lifespan, and ultimately, compromised print jobs.

The high-intensity UV light emitted by LEDs generates significant heat. Without adequate cooling, this heat can quickly build up, leading to a cascade of problems. One of the most immediate concerns is the degradation of the LED chips themselves. Elevated temperatures shorten the operational life of LEDs, causing them to dim prematurely or fail entirely. This translates directly into increased maintenance costs and downtime for printing presses.

Beyond the LEDs, excessive heat can also impact other components within the curing system, including power supplies and associated electronics. This can lead to erratic performance and the potential for complete system failure. For printers operating on tight deadlines, such disruptions are simply not an option.

Thermal Management Strategies for Reliable Operation

Effective cooling strategies are therefore essential for maintaining stable operating temperatures. A common and highly effective method is the use of forced air cooling. This involves circulating air over heat sinks integrated with the LED modules. The heat sinks, typically made of aluminum or copper, have a large surface area with fins, allowing for efficient transfer of heat from the LEDs to the air. Fans then expel the heated air, drawing in cooler ambient air to continue the cycle.

Another robust cooling solution is liquid cooling. This method is often employed in high-power or space-constrained applications where air cooling might not be sufficient. A closed-loop system circulates a coolant, usually a mixture of water and an additive to prevent corrosion and freezing, through channels within the LED modules. The heated coolant then flows to a heat exchanger, where it is cooled by air or a separate cooling unit before being recirculated. Liquid cooling offers superior thermal conductivity and can manage higher heat loads more effectively than air cooling, ensuring consistent performance even under demanding conditions.

The design of the heat sink itself is a critical aspect of thermal management. Engineers meticulously calculate the required surface area, fin density, and material properties to dissipate the generated heat efficiently. Proper airflow pathways are also crucial to ensure that the cooling medium can effectively reach and remove heat from all parts of the LED array.

The Intricate World of Optics in UV Curing

While cooling manages the heat generated, the optics design dictates how the UV light is delivered to the substrate. This is where precision and understanding of light physics come into play. The goal of the optics is to concentrate and direct the UV energy onto the ink or coating, ensuring efficient polymerization.

The primary components of the optics system typically include lenses and reflectors. Lenses are used to focus the emitted UV light, shaping the beam to achieve the desired intensity and uniformity across the printed area. Different types of lenses, such as Fresnel lenses or aspheric lenses, are selected based on the specific application and the desired beam profile. The material of the lens is also important, requiring high transmissivity in the UV spectrum to minimize light loss.

Reflectors are often used in conjunction with LEDs to capture and redirect any light that is emitted away from the substrate. These are typically highly polished surfaces designed to bounce UV photons back towards the target area, increasing the overall energy efficiency of the curing system. The shape and placement of these reflectors are carefully engineered to achieve a uniform light distribution.

Optimizing Light Delivery for Various Printing Processes

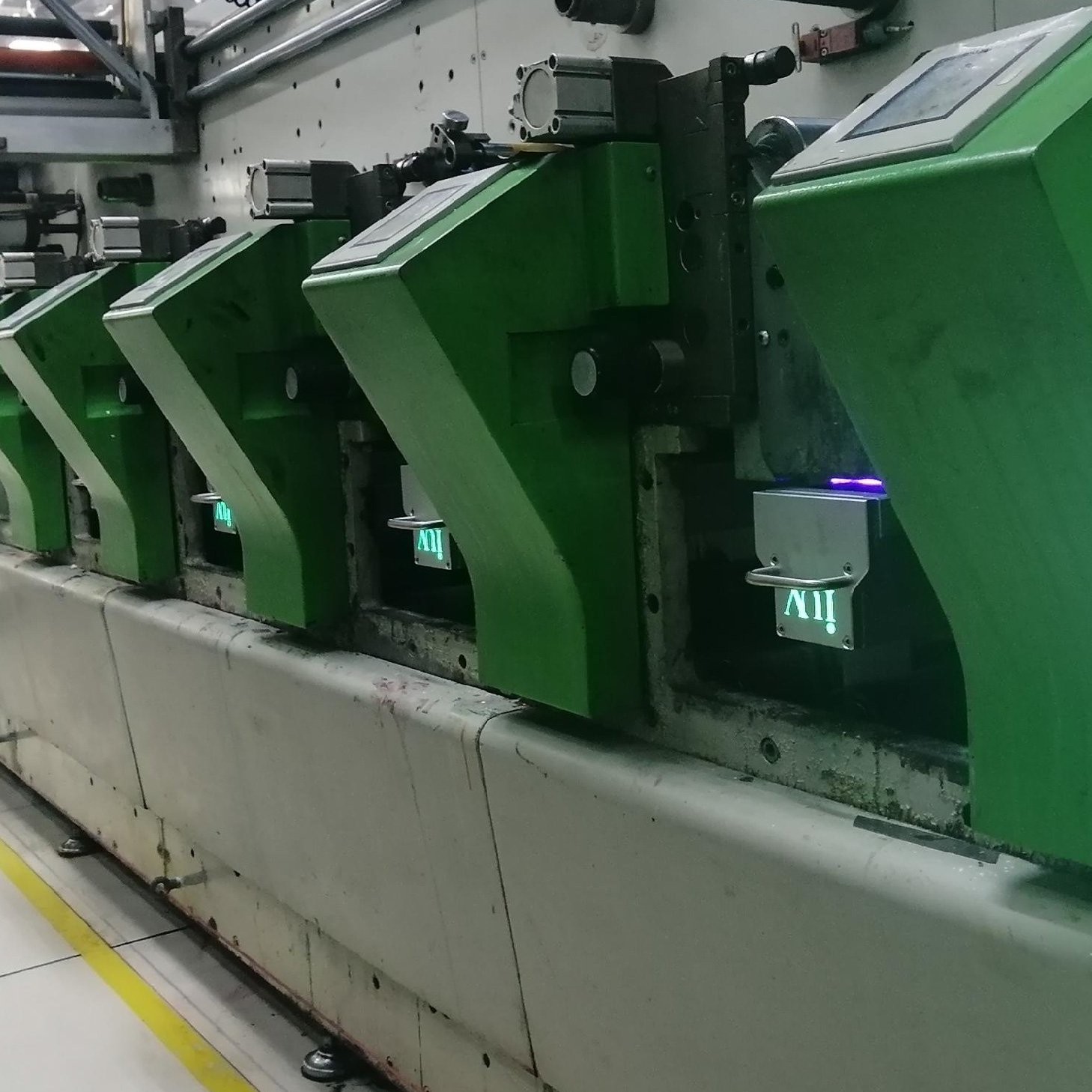

The specific demands of different printing processes necessitate tailored optics designs. In narrow web printing, for instance, where high speeds and precise registration are critical for labels and packaging, the optics must deliver a consistent and intense UV dose across the entire web width. This requires meticulous attention to uniformity, ensuring that no areas are under-cured or over-cured, which could lead to adhesion issues or ink brittleness.

For flexographic printing, often used for flexible packaging and labels, the optics need to accommodate the dynamic surface of the substrate as it moves through the press. The focused UV light must penetrate the ink layer effectively, polymerizing it rapidly without damaging the flexible material. The ability to fine-tune the optics to match the ink thickness and substrate type is a significant advantage.

In offset printing, particularly in sheetfed applications for high-quality commercial jobs, the optics design must ensure uniform illumination across the entire sheet. This is crucial for achieving consistent color reproduction and gloss levels. The system needs to deliver a powerful and even cure, even on challenging substrates like coated papers or plastics.

The Synergy: How Cooling and Optics Work Together

It’s vital to understand that cooling and optics are not independent entities; they are intrinsically linked. The performance of the optics is directly influenced by the temperature of the LEDs. As LEDs heat up, their spectral output can shift, and their intensity can decrease. This means that even a perfectly designed optics system will underperform if the LEDs are not kept at their optimal operating temperature by an effective cooling system.

Conversely, a highly efficient cooling system that doesn’t deliver the UV light effectively to the substrate is also a wasted effort. The energy generated by the LEDs, which the cooling system is working to manage, needs to be efficiently channeled by the optics for successful curing.

This synergy means that manufacturers of LED UV curing systems must take a holistic approach to design. They need to consider the thermal characteristics of the LEDs, the requirements of the printing process, and the physics of light delivery simultaneously. This involves sophisticated simulation tools and rigorous testing to ensure that both cooling and optics are perfectly balanced for optimal performance.

Achieving Uniformity and Intensity: Key Metrics

When evaluating LED UV curing systems, two key metrics related to optics and cooling are uniformity and intensity.

Uniformity refers to the evenness of the UV light distribution across the irradiated area. For curing systems, this is often measured as a percentage, with higher percentages indicating better uniformity. Poor uniformity can lead to uneven curing, resulting in adhesion problems, poor rub resistance, and inconsistent gloss.

Intensity, also known as irradiance, is the amount of UV power delivered per unit area, typically measured in Watts per square centimeter (W/cm²). Higher intensity generally translates to faster curing speeds. However, the required intensity varies depending on the ink or coating chemistry and the desired curing depth. An effective cooling system ensures that the LEDs can operate at the required intensity for extended periods without overheating.

Future Trends and Considerations

As the printing industry continues to embrace LED UV curing, advancements in both cooling and optics design will drive further improvements. We can expect to see more integrated cooling solutions, perhaps even utilizing novel materials or thermoelectric cooling for even greater efficiency. In optics, advancements in micro-optics and meta-materials may lead to even more precise control over light delivery, enabling finer adjustments and improved performance for specialized applications.

Ultimately, a deep understanding of how cooling and optics design interact is fundamental for any printer looking to leverage the full potential of LED UV curing technology. By prioritizing these critical elements, print businesses can ensure reliable operation, achieve superior print quality, and maintain a competitive edge in today’s demanding market.