UV curing flexo printing offers incredible benefits for today’s print shops. It’s a technology that’s transforming the narrow web printing landscape. Understanding its nuances is key to unlocking superior print quality and efficiency.

Flexographic printing, or flexo, is a versatile method. It uses a raised image carrier, typically a flexible relief plate. Ink is transferred from the plate to the substrate. This process is ideal for a wide range of materials, including films, foils, and paper. For label printing, flexo has long been a dominant force. Its speed and cost-effectiveness make it a go-to solution.

Traditional flexo printing often uses heat-set or solvent-based inks. These require drying tunnels or extensive ventilation. They can also lead to VOC emissions. This is where UV curing technology changes the game.

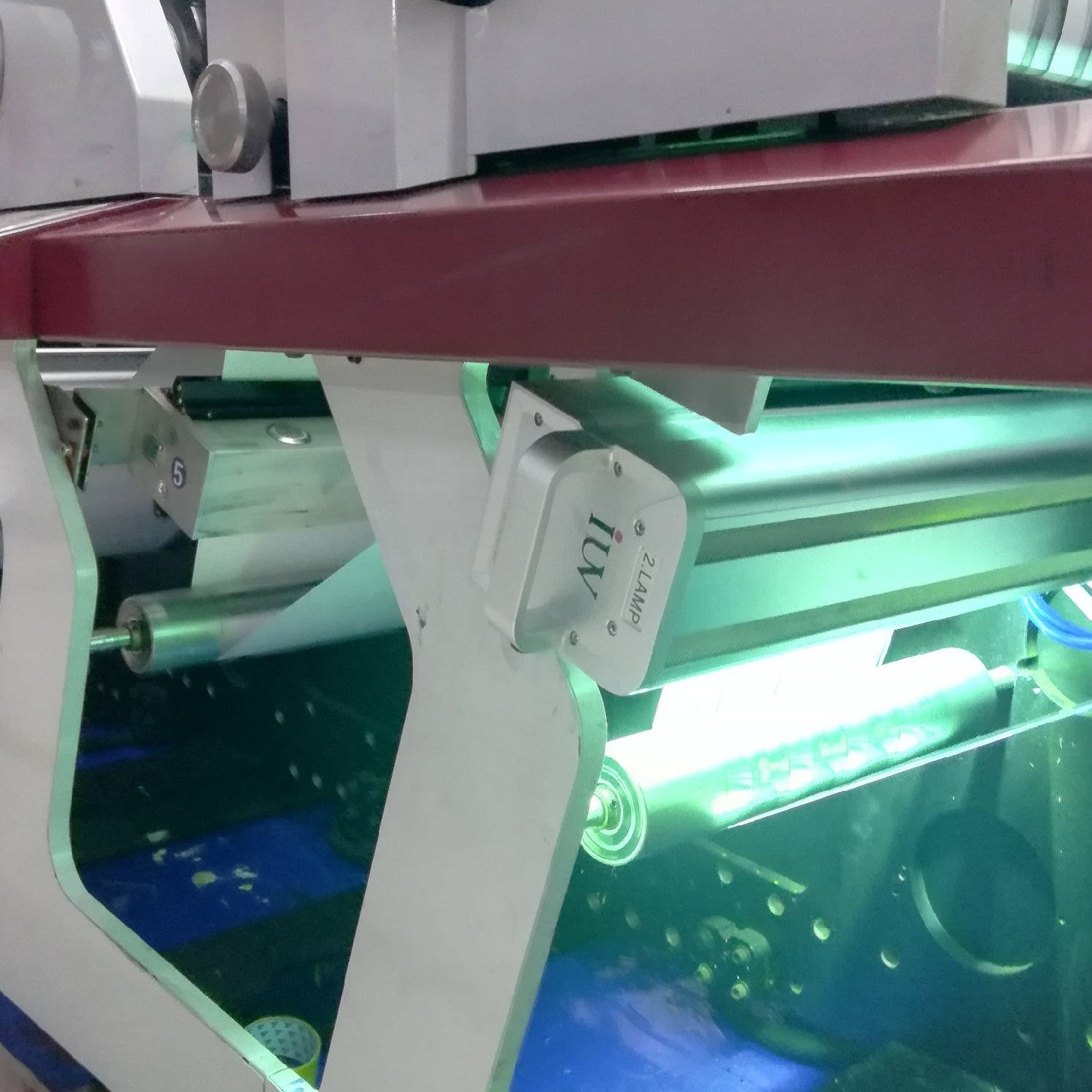

UV curing uses ultraviolet light to instantly dry inks and coatings. The inks contain photoinitiators. When exposed to UV light, these initiators trigger a rapid polymerization process. The ink transforms from a liquid to a solid state almost instantaneously. This is a photopolymerization reaction.

LED UV curing is the latest advancement in this field. Unlike traditional mercury vapor lamps, LED UV systems use light-emitting diodes. These diodes emit UV light within a specific wavelength range. This offers several advantages over older UV lamp technology.

One major benefit is energy efficiency. LEDs consume significantly less power than mercury lamps. They also generate less heat. This is crucial when printing on heat-sensitive substrates. Think of thin films or delicate papers used in label printing. Reducing heat buildup prevents substrate distortion and maintains print integrity.

Another advantage is lamp longevity. LED UV lamps have a much longer operational lifespan. They can last tens of thousands of hours. This means less downtime for lamp replacements and maintenance. It translates to lower operating costs over time.

Fast curing speeds are a hallmark of UV flexo printing. The instant drying means faster press speeds are possible. This boosts productivity. You can achieve higher throughput without compromising on print quality. This is a significant advantage for narrow web printers handling high-volume orders.

The quality of prints produced with UV curing is often exceptional. UV inks are known for their vibrant colors and sharp dot reproduction. They adhere well to a variety of substrates. This is important for demanding applications in label printing. The inks are also highly durable. They resist scuffing, scratching, and chemical exposure. This durability is vital for product labels that endure harsh environments.

Compared to offset printing, flexo printing offers distinct advantages for certain applications. Flexo excels on flexible packaging and labels. It can print on a wider range of substrates, including uneven surfaces. Offset printing, or lithography, is generally known for its fine detail and smooth solids. It’s often used for high-quality commercial printing. However, for narrow web applications like labels and flexible packaging, flexo with UV curing is often the preferred choice.

The environmental benefits of UV curing are also noteworthy. UV inks are typically 100% solid. They contain very few or no volatile organic compounds (VOCs). This reduces air pollution. It also creates a safer working environment for press operators. There’s no need for extensive ventilation systems associated with solvent inks. This simplifies pressroom design and reduces operational complexity.

When considering UV curing for your flexo press, there are a few things to keep in mind. The initial investment in an LED UV curing system can be higher. However, the long-term savings in energy, consumables, and maintenance often offset this cost. It’s an investment in efficiency and quality.

Proper ink formulation is also key. UV inks are specialized. They are designed to cure under specific UV wavelengths. Matching the ink to the LED UV lamp’s output is essential for optimal curing. Printers need to work with ink suppliers who understand LED UV technology.

Substrate compatibility is another factor. While UV inks adhere well to many materials, testing is always recommended. Different substrates absorb UV light differently. This can affect curing performance.

Maintenance of the UV curing system is relatively straightforward. Keeping the LED heads clean and ensuring proper alignment is important. Unlike traditional lamps, LEDs do not degrade in output over time in the same way. Their consistent performance is a major plus.

The versatility of UV flexo printing extends to special effects. High-gloss varnishes, matte finishes, and textured effects can all be achieved with UV coatings. This allows for creative design possibilities. It helps brands stand out on the shelf.

In narrow web printing, where precision and speed are paramount, UV curing flexo is a powerful combination. It addresses many of the challenges faced by printers today. From enhancing print quality to improving operational efficiency and reducing environmental impact, the benefits are substantial.

For label printers looking to stay competitive, embracing UV curing technology is a strategic move. It allows for faster turnaround times. It enables the production of high-quality, durable labels. It also aligns with growing demands for more sustainable printing practices.

The transition to LED UV curing involves understanding the technology. It requires careful selection of equipment and consumables. But the rewards are significant. Faster speeds, better print results, and a more environmentally friendly process make it an attractive option for modern printing operations. It’s a technology that’s not just improving printing, but redefining it for the future.