The world of printing is constantly evolving. Innovations push the boundaries of what’s possible. One such game-changer is UV curing technology. It has transformed how we think about ink drying. This article delves into the science of UV curing. We will explore its profound impact on ink drying processes. This is especially relevant in label printing and narrow web applications.

Traditional drying methods often relied on heat and air. These methods could be slow and energy-intensive. They sometimes affected the substrate. Ink could also migrate. UV curing offers a fundamentally different approach. It uses ultraviolet light. This light initiates a rapid chemical reaction. This reaction solidifies (cures) the ink. It happens almost instantaneously.

The core of a UV curing system is the UV lamp. These lamps emit specific wavelengths of ultraviolet light. These wavelengths are carefully chosen. They must match the photoinitiators present in the UV-curable ink. Photoinitiators are special molecules. When struck by UV photons, they become highly reactive. They generate free radicals or cations. These entities then initiate polymerization. Polymerization is the process of forming long molecular chains. These chains link the ink’s components together. This transforms the liquid ink into a solid, durable film.

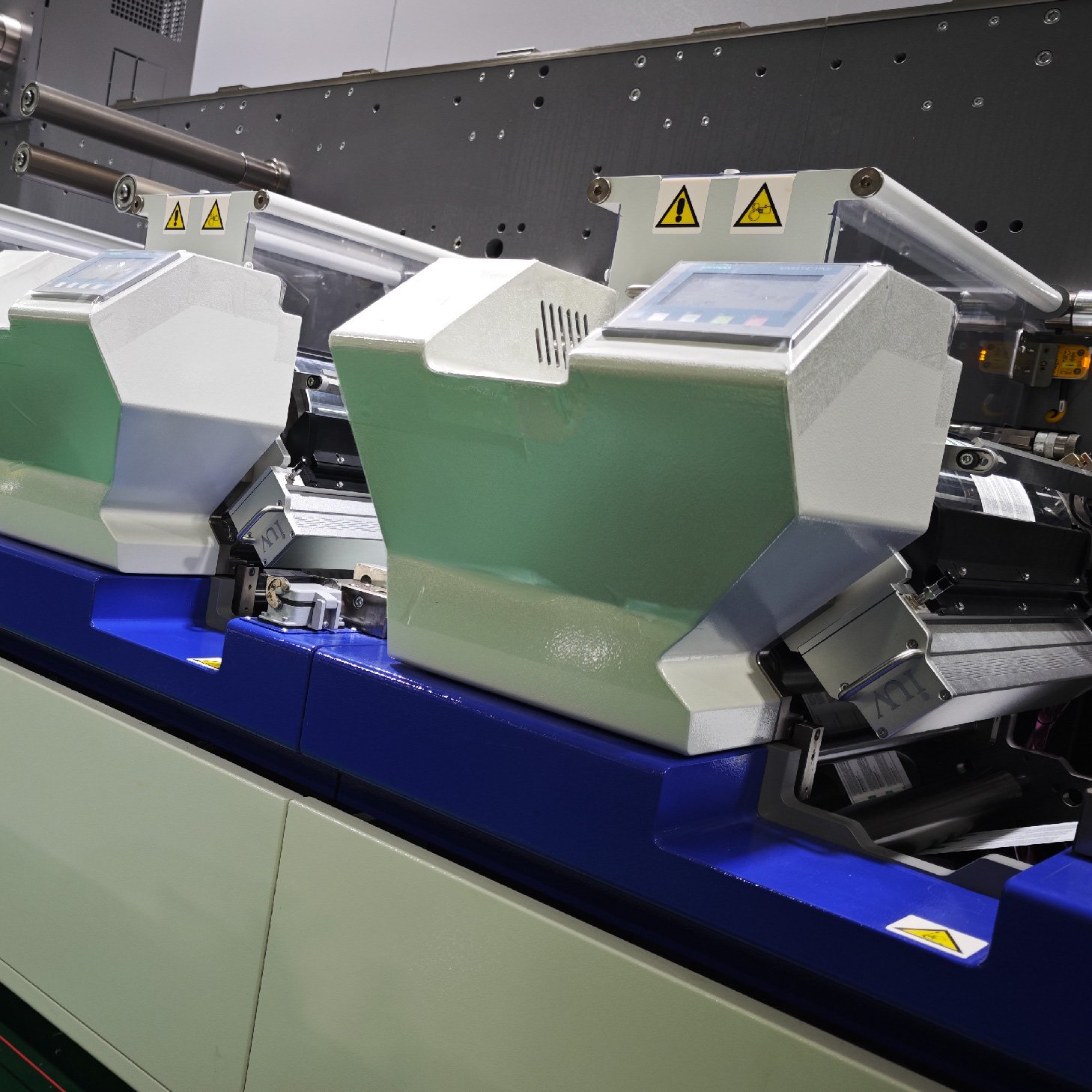

In flexographic printing, UV curing has become a standard. Narrow web presses for labels and packaging frequently employ UV units. The speed of flexo presses demands fast drying. UV curing excels here. It cures ink in fractions of a second. This prevents ink transfer issues. It also allows for immediate post-processing. Think about overprinting or cutting. This capability significantly boosts production efficiency. The inks used are specially formulated. They contain monomers, oligomers, and photoinitiators. When exposed to UV light, these components cross-link. This creates a robust ink layer.

Offset lithography, or sheetfed and web offset, also benefits greatly. For shorter runs and specialty applications, UV offset inks are common. They offer excellent print quality. They cure instantly under UV lamps. This means sheets can be stacked immediately. There’s no waiting for ink to dry. This is a huge advantage in busy print shops. It reduces turnaround times. It also minimizes the risk of smudging or scratching. The ability to print on non-absorbent substrates is another key benefit. Think of plastics and foils. Traditional inks struggle with these. UV inks adhere well. They cure to a hard, resistant finish.

The science behind the LED UV curing revolution is fascinating. Traditional UV lamps are mercury-based. They emit a broad spectrum of UV light. They also generate significant heat. This heat can be detrimental to sensitive substrates. It increases energy consumption. LED UV lamps are different. They use Light Emitting Diodes. These diodes emit UV light within a very narrow wavelength band. This band is precisely matched to the photoinitiators. This offers several advantages. Energy efficiency is much higher. LEDs consume less power than mercury lamps. They also produce very little heat. This allows for printing on heat-sensitive materials. Think of thin films or certain types of paper.

The focused wavelength of LED UV also means less wasted energy. The light is directed where it’s needed. This can lead to even faster cure speeds. It can also result in more thorough curing. This translates to better ink performance. We’re talking about improved rub resistance. We’re talking about enhanced chemical resistance. The lifespan of LED lamps is also considerably longer. They don’t contain mercury. This makes them more environmentally friendly. Disposal is also simpler.

The impact on ink drying is profound. UV curing systems, both traditional and LED, offer instant drying. This is not just about speed. It’s about the quality of the dry film. The rapid polymerization locks ink components in place. This prevents migration of plasticizers or other additives. This is critical for food packaging applications. Safety regulations are strict. UV cured inks can meet these stringent requirements. The resulting ink film is dense. It has excellent adhesion. It’s resistant to abrasion and chemicals.

Consider the environmental benefits. UV curing eliminates VOCs (Volatile Organic Compounds). Traditional solvent-based inks release VOCs into the atmosphere. This contributes to air pollution. UV inks are 100% solids. When they cure, there are no solvents to evaporate. This makes UV printing a much cleaner process. It’s better for the environment. It’s also better for the print shop workers. No need for extensive ventilation systems for solvent fumes.

In conclusion, UV curing systems represent a significant leap forward. They enhance speed, quality, and sustainability in printing. The science of UV light interacting with photoinitiators drives this transformation. From narrow web flexo to offset, the benefits are clear. Instant drying, superior durability, and environmental advantages make UV curing a compelling choice. The continued development of LED UV technology promises even greater efficiencies. It opens up new possibilities for printers worldwide. The future of ink drying is undeniably UV.