In the dynamic world of printing, achieving peak performance from UV inks is a constant pursuit. This optimization hinges on a deep understanding of the interplay between ink chemistry and the light source used for curing. Among the most crucial factors is wavelength matching. This principle dictates how effectively UV energy is absorbed by the photoinitiators within the ink, leading to rapid and complete polymerization. For label printing, flexographic printing, offset printing, and narrow web applications, getting this match right is paramount.

Understanding UV Curing and Photoinitiators

UV curing technology relies on a chemical reaction initiated by ultraviolet light. This reaction transforms liquid ink into a solid, durable film. The key players in this process are photoinitiators. These molecules are specifically designed to absorb UV photons and generate reactive species, typically free radicals or cations. These reactive species then initiate a chain reaction, causing the ink’s monomers and oligomers to cross-link and harden.

The efficiency of this initiation process is directly tied to the absorption spectrum of the photoinitiator. Each photoinitiator molecule has a specific range of wavelengths it can absorb most effectively. This is where wavelength matching becomes indispensable.

The Science Behind Wavelength Matching

LED UV curing systems offer precise control over the emitted light spectrum. Unlike traditional mercury vapor lamps, LEDs emit light within very narrow wavelength bands. This precision allows printers to select LEDs whose output spectrum aligns closely with the absorption peak of the photoinitiators used in their UV inks.

When the emitted UV wavelength from the LED source precisely matches the photoinitiator’s absorption maximum, the ink absorbs energy much more efficiently. This leads to several tangible benefits:

- Faster Cure Speeds: With efficient energy absorption, the photoinitiator can generate reactive species more rapidly. This accelerates the polymerization process, allowing for faster line speeds in printing.

- Improved Through-Cure: A precise wavelength match ensures that UV energy penetrates the ink film effectively, leading to complete curing throughout its depth. This is vital for achieving desired ink properties like adhesion, scratch resistance, and chemical resistance.

- Reduced Energy Consumption: By using a more efficient curing process, less UV energy is needed to achieve a full cure. This translates to lower energy bills and a reduced carbon footprint for the printing operation.

- Minimized Ink Migration: Incomplete curing can leave uncured ink components or photoinitiator residues. This can lead to ink migration issues, particularly problematic in food packaging and sensitive applications. Optimal wavelength matching helps ensure a thorough cure, minimizing these risks.

- Broader Ink Formulation Possibilities: Understanding wavelength matching opens doors for formulators. They can develop inks with specific performance characteristics by selecting photoinitiators tailored to particular LED wavelengths.

Wavelengths in Focus: Common LED UV Systems

The printing industry predominantly uses LED UV systems emitting at specific wavelengths. The most common are:

- 365 nm: This wavelength is widely used and is effective for many general-purpose UV inks. Photoinitiators with absorption peaks around 365 nm are abundant and offer good performance.

- 395 nm: This longer wavelength is increasingly popular. It offers better penetration through colored inks and is less prone to surface cure issues. Many modern UV ink formulations are optimized for 395 nm LEDs.

- 405 nm: While sometimes grouped with 395 nm, this distinct wavelength is also employed. It’s particularly useful for certain ink types and substrates where even greater penetration is needed.

The choice of LED wavelength directly influences the selection of photoinitiators. A formulator designing a UV ink for a 365 nm LED system will select photoinitiators that exhibit strong absorption at this specific wavelength. Conversely, an ink designed for a 395 nm system will incorporate photoinitiators optimized for that spectral output.

Implications for Different Printing Processes

The importance of wavelength matching is felt across various printing sectors, each with its unique demands.

Narrow Web and Label Printing

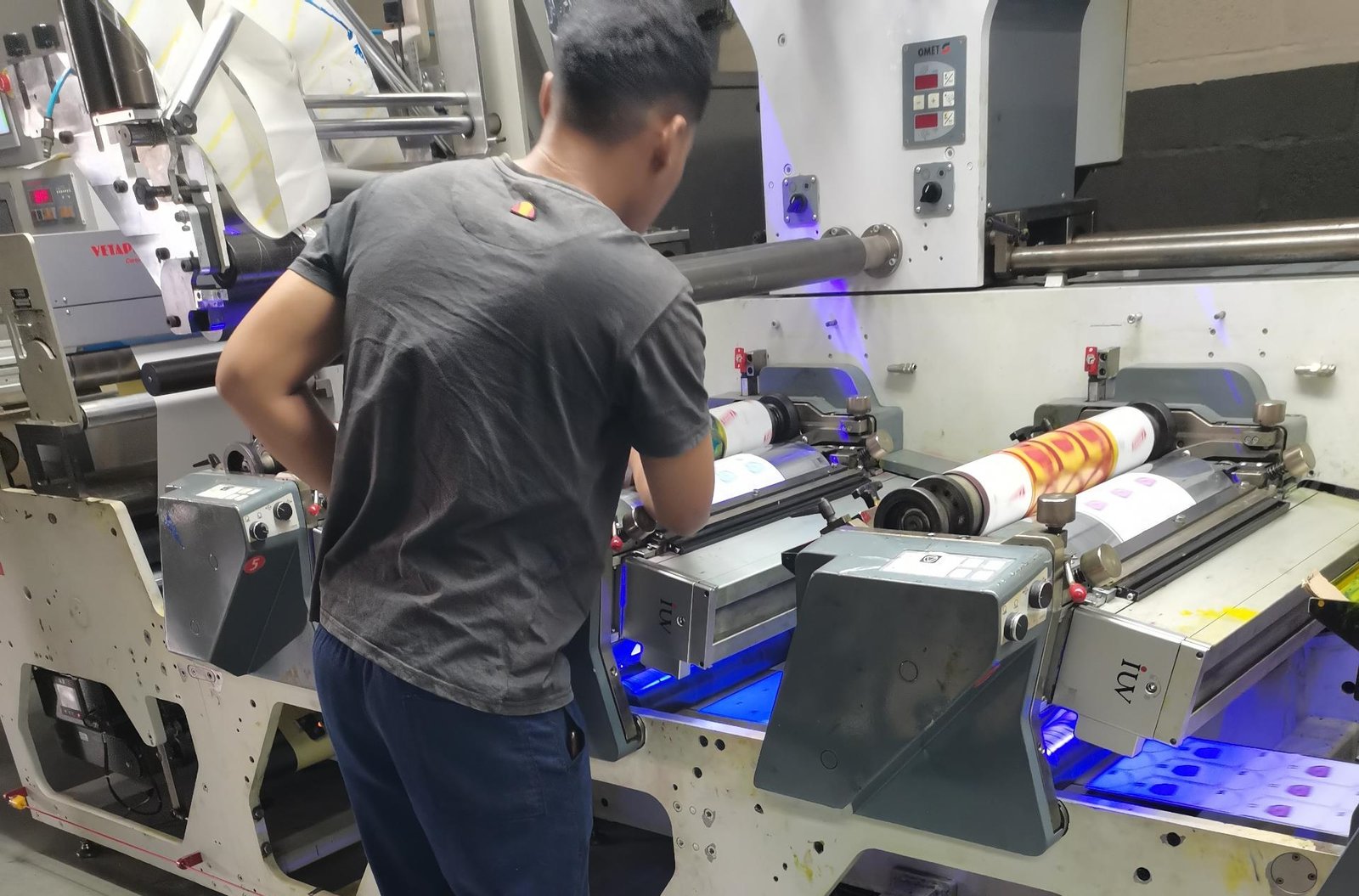

Narrow web presses, commonly used for labels and flexible packaging, often operate at very high speeds. In this environment, rapid and consistent curing is non-negotiable. Wavelength matching ensures that the UV energy delivered by LED systems is efficiently converted into curing energy, keeping pace with high production rates. It also plays a crucial role in achieving the demanding aesthetic and functional requirements of labels, such as vibrant colors, sharp details, and robust durability.

Flexographic Printing

Flexography is a versatile printing process used for a wide range of substrates, from thin films to thick cardboard. UV-curable inks are extensively used in flexo, especially for packaging. The efficiency gains from wavelength-matched LEDs mean faster throughput and reduced downtime. Furthermore, flexo often deals with thicker ink layers, making deep through-cure essential. Proper wavelength selection ensures that the UV energy reaches the entire ink film, preventing issues like surface tackiness or poor adhesion.

Offset Printing (Sheet-fed and Web)

In offset lithography, UV inks offer excellent print quality and instant drying. Sheet-fed offset is often used for high-end commercial printing and packaging, where pristine print quality is key. Web offset, particularly heatset with UV, is used for publications and direct mail. Wavelength matching in offset printing ensures that the rapid curing process doesn’t negatively impact the delicate ink transfer and dot gain. It allows for immediate handling of printed sheets, enhancing productivity.

Challenges and Considerations

While the benefits are clear, achieving optimal wavelength matching isn’t without its considerations:

- Substrate Effects: Different substrates absorb or reflect UV light differently. White or opaque substrates may reflect UV light, potentially requiring adjustments in LED power or wavelength. Transparent or colored substrates can absorb UV light, necessitating wavelengths that penetrate effectively.

- Ink Film Thickness: Thicker ink films require more UV energy to achieve a full cure. Wavelengths that offer better penetration, like 395 nm or 405 nm, are often preferred for thicker layers.

- Pigment Absorption: Pigments within the ink can also absorb UV light, competing with the photoinitiators. This means that ink formulations must be carefully balanced to ensure sufficient UV energy reaches the photoinitiators for curing. Darker or highly pigmented inks may require specific photoinitiator packages and optimized LED wavelengths.

- Photoinitiator Compatibility: Not all photoinitiators are equally effective at all wavelengths. Formulators must select photoinitiator systems that are well-suited to the specific LED output they intend to use.

- Investment in Equipment: Transitioning to LED UV curing systems involves an upfront investment. However, the long-term savings in energy, consumables, and increased productivity often justify the cost. Ensuring the chosen LED system’s wavelength aligns with available ink technologies is crucial for maximizing this investment.

The Future of UV Ink Optimization

The trend towards UV LED curing is undeniable, driven by its energy efficiency, environmental benefits, and precise control. As LED technology advances, we can expect to see even more specialized LED systems and ink formulations emerging. The ongoing research into novel photoinitiators and UV-curable resins will continue to push the boundaries of performance.

For printers, staying abreast of these developments is key. Understanding the fundamental principle of wavelength matching empowers them to make informed decisions about their ink and curing equipment. It’s not just about applying ink; it’s about intelligently delivering the right energy at the right time to achieve superior results, from the first print to the last. By mastering this synergy, printers can unlock the full potential of their UV ink systems, ensuring vibrant, durable, and cost-effective printed products.