Broadening Horizons: How UV Curing Systems Revolutionize Substrate Options in Narrow Web Printing

In the dynamic world of narrow web printing, staying competitive means adapting to evolving customer demands and exploring new material possibilities. For a long time, the choice of printing substrates was a significant limitation. Traditional inks often required heat or air drying, which restricted the types of materials that could be effectively printed upon. This is where the transformative power of UV curing systems truly shines, dramatically expanding the compatibility of printing presses with a wider array of substrates.

For label printers, this shift has been nothing short of a game-changer. Previously, printing on challenging surfaces like certain plastics, metallic foils, or heat-sensitive materials often meant compromising on ink adhesion, durability, or even the integrity of the substrate itself. UV curing technology, particularly the advancements seen in LED UV systems, has fundamentally altered this landscape.

The Science Behind UV Curing

At its core, UV curing is a photochemical process. It utilizes ultraviolet light to instantly cure (harden) specially formulated inks, coatings, and adhesives. When these UV-reactive materials are exposed to UV light, photoinitiators within their composition absorb the light energy. This triggers a rapid chain reaction, transforming the liquid ink into a solid, durable film in a matter of seconds, or even fractions of a second.

This instant curing process offers several key advantages. Firstly, it eliminates the need for extended drying times, which in turn increases printing speeds and overall throughput. Secondly, the cured ink film is remarkably robust, exhibiting excellent resistance to abrasion, chemicals, and fading. This durability is paramount for labels and packaging that endure harsh environments or extensive handling.

The LED UV Advantage

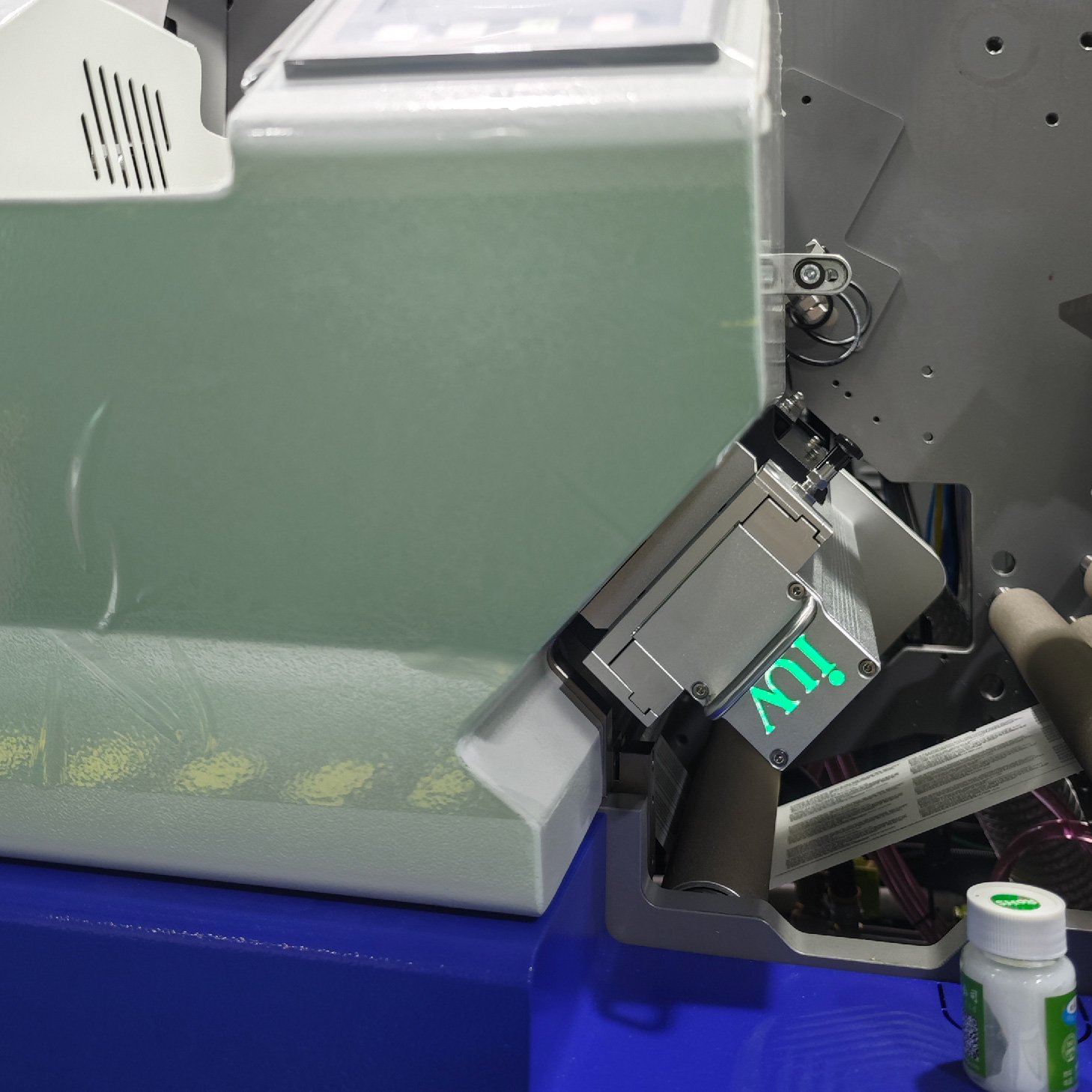

While traditional mercury vapor UV lamps have been the workhorse of UV curing for years, the advent of LED UV technology has brought about further significant improvements, especially concerning substrate compatibility. LED UV systems offer a more focused and controllable wavelength of UV light. This precision allows for more efficient curing of specialized UV inks and coatings designed for specific substrates.

One of the most significant benefits of LED UV is its lower heat output compared to mercury lamps. This is crucial when printing on heat-sensitive materials that could warp, melt, or degrade under the intense heat generated by traditional UV systems. Think about delicate films, certain synthetic papers, or even pre-finished packaging materials. With LED UV, printers can confidently apply high-quality graphics without damaging the underlying substrate.

Expanding the Substrate Palette

This improved heat management, coupled with the precise control offered by LED UV, unlocks a vast new world of printing possibilities.

- Plastics and Films: Polypropylene (PP), polyethylene (PE), polyester (PET), and other plastic films are now readily printable. UV-curable inks adhere exceptionally well to these non-porous surfaces, providing vibrant colors and durable finishes for product labels, shrink sleeves, and flexible packaging.

- Metallic and Holographic Foils: Achieving sharp, vibrant prints on metallic and holographic substrates used to be a challenge due to potential ink adhesion issues. UV curing ensures that inks bond effectively to these reflective surfaces, preserving their visual impact without dulling their shine.

- Specialty Papers: Papers with unique textures, coatings, or those designed for specific applications can now be handled with greater ease. UV curing prevents excessive ink penetration into textured papers, maintaining crisp dot definition.

- Direct Printing on Packaging: Beyond labels, UV curing enables direct printing on a variety of packaging materials that were once considered difficult. This includes certain types of cardboard, rigid plastics, and even some textured surfaces, opening doors for unique brand packaging solutions.

Impact on Different Printing Processes

The benefits of UV curing extend across various printing methods commonly used in narrow web applications:

- Flexographic Printing: UV flexo inks are widely used for label and packaging printing. The rapid curing allows for high-speed production runs with excellent print quality on a diverse range of films and papers. The ability to print multiple colors inline without drying delays is a significant productivity booster.

- Offset/Lithographic Printing: While traditionally associated with heatset or coldset inks, UV offset inks are increasingly adopted in narrow web for their fast drying and superior durability. This is particularly beneficial for high-volume label runs where quick turnaround is essential.

- Screen Printing: UV screen printing inks offer exceptional opacity and build, making them ideal for high-impact graphics and special effects. Their compatibility with various substrates, from plastics to metal, is a key advantage in niche label applications.

Choosing the Right UV System

When selecting a UV curing system, especially for expanded substrate compatibility, several factors come into play. The type of UV lamp (mercury vapor vs. LED), the wavelength output, the power intensity, and the cooling mechanism are all critical considerations. For printers looking to maximize their substrate options, particularly with heat-sensitive materials, LED UV systems often present the most versatile and energy-efficient solution.

Furthermore, the formulation of the UV ink or coating is equally important. Manufacturers offer specialized UV inks designed to adhere to specific substrates, offering enhanced flexibility, adhesion, and resistance properties. Collaborating with ink suppliers and equipment manufacturers is key to identifying the optimal combination for your printing needs.

The Future is Flexible

The ongoing advancements in UV curing technology, especially with LED UV, continue to push the boundaries of what’s possible in narrow web printing. As printers embrace these innovations, they gain the flexibility to take on a wider range of projects, cater to more diverse client needs, and ultimately, enhance their competitive edge in the marketplace. The ability to print vibrant, durable graphics on virtually any substrate imaginable is no longer a distant dream, but a present-day reality thanks to the power of UV curing.