Enhancing Print Durability and Ink Adhesion with UV Curing Systems

In the dynamic world of printing, achieving exceptional durability and robust ink adhesion is paramount. This is especially true for applications like label printing, flexographic printing, offset printing, and narrow web printing, where the final product often faces demanding conditions. Modern printing businesses are increasingly turning to UV curing systems to meet these challenges head-on. These advanced technologies offer a significant leap forward in print quality and performance.

Understanding UV Curing Technology

UV curing, or ultraviolet curing, is a photochemical process. It uses intense ultraviolet light to initiate a rapid curing, or hardening, of inks, coatings, and adhesives. When UV light strikes a specially formulated liquid ink or coating, it triggers photoinitiators within the formulation. These initiators absorb the UV energy and start a chain reaction, cross-linking the monomers and oligomers. This polymerization process transforms the liquid into a solid, durable film almost instantaneously.

Traditional drying methods, like heat or solvent evaporation, can be slow and may not offer the same level of performance. Heat drying can sometimes distort thinner substrates, and solvent evaporation releases volatile organic compounds (VOCs) into the environment, which is a growing concern for sustainability. UV curing, in contrast, is a fast, efficient, and often more environmentally friendly process.

The Impact on Print Durability

One of the most significant benefits of UV curing is its dramatic effect on print durability. UV-cured inks and coatings form a tough, resilient surface. This makes printed materials highly resistant to scratching, scuffing, and abrasion. For labels that will be handled frequently, or for packaging that needs to withstand transit and handling, this enhanced durability is invaluable. Think of product labels on bottles that might be wiped down, or shipping labels that are subjected to the rigors of logistics. UV curing ensures the print remains legible and intact.

Furthermore, UV-cured finishes offer excellent resistance to chemicals and moisture. This is crucial for many industrial labels, food and beverage packaging, and outdoor signage. The cross-linked polymer structure created by UV curing acts as a barrier, preventing liquids and common solvents from penetrating and damaging the printed image. This means colors stay vibrant and sharp, even when exposed to challenging environments.

Boosting Ink Adhesion

Ink adhesion is the critical factor that determines how well the ink bonds to the substrate. Poor adhesion leads to ink flaking, peeling, and a compromised final product. UV curing systems, when used with appropriate inks and substrates, excel at promoting strong ink adhesion. The rapid polymerization process creates a tight bond between the ink and the surface of the material.

This is particularly important in flexographic and offset printing, where high speeds and precise ink laydown are essential. UV-cured inks adhere exceptionally well to a wide range of substrates, including plastics, foils, and coated papers, which can sometimes be challenging for conventional inks. This versatility allows printers to expand their capabilities and offer high-quality prints on diverse materials.

For narrow web printing, often used for producing labels and packaging, the ability of UV inks to adhere firmly is a major advantage. The compact nature of narrow web presses means efficient curing is essential to maintain speed and throughput. UV curing systems integrate seamlessly into these presses, providing instant drying and excellent adhesion without slowing down production.

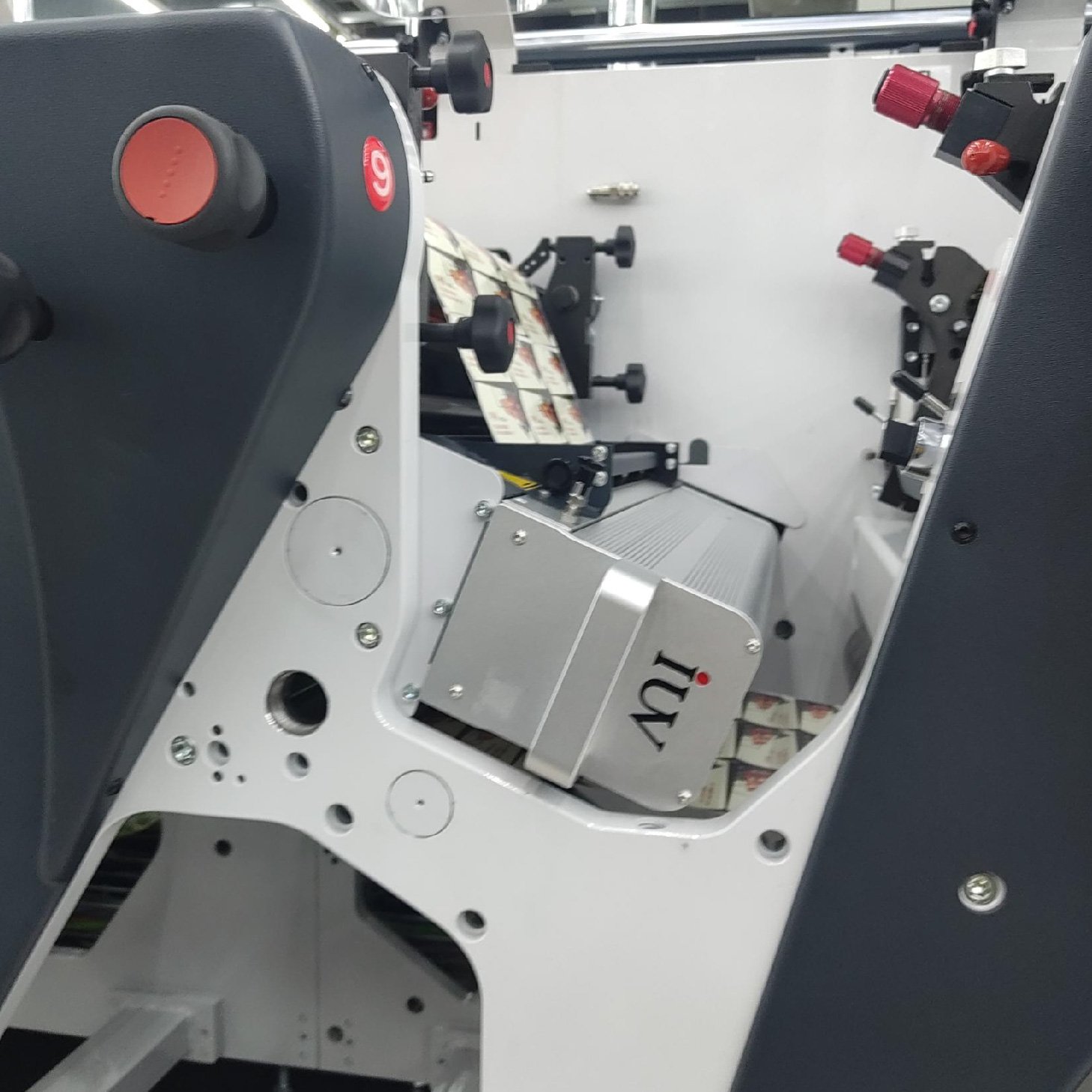

LED UV Curing: The Next Frontier

While traditional mercury-vapor UV lamps have been the standard for years, LED UV curing technology represents a significant advancement. Light Emitting Diode (LED) UV systems offer several compelling advantages. They consume less energy than mercury lamps, leading to substantial cost savings. They also have a much longer lifespan, reducing maintenance and replacement costs.

Moreover, LED UV systems generate less heat. This is a critical benefit when printing on heat-sensitive substrates, such as thin films or certain types of plastics, common in label and narrow web applications. The focused spectrum of UV light from LEDs also allows for more efficient curing, often at higher press speeds. This means printers can achieve faster production times and greater efficiency.

The precise wavelength control offered by LED UV systems can also lead to more consistent curing results, further enhancing both durability and adhesion. This precision is vital for brand owners who demand consistent color and finish across all their printed materials.

Applications in Key Printing Sectors

- Label Printing: UV curing is a cornerstone of modern label printing. It enables the production of durable, scratch-resistant labels for everything from beverages and food products to industrial chemicals and automotive parts. Enhanced adhesion ensures labels stay put, even on curved or irregularly shaped containers.

- Flexographic Printing: In flexo, UV inks provide vibrant colors and sharp detail. The rapid curing allows for high-speed printing on a variety of flexible packaging materials and labels. The excellent adhesion is crucial for multi-layer packaging and applications requiring resistance to flexing and creasing.

- Offset Printing: For commercial printing and packaging, UV offset inks offer superior print quality and immediate finishing. Projects can be stacked, cut, or folded right off the press without smudging or offsetting, significantly improving workflow efficiency. The durability of UV coatings protects high-value print jobs.

- Narrow Web Printing: This sector, focused on labels and short-run packaging, heavily relies on UV curing. The compact nature of the presses and the need for quick turnarounds make UV curing an ideal fit. It allows for inline finishing operations, such as lamination and die-cutting, to occur immediately after printing.

Conclusion

UV curing systems have transformed the printing industry, offering unparalleled benefits in print durability and ink adhesion. From enhancing the longevity of labels to ensuring vibrant, robust graphics on packaging, the technology provides a competitive edge. With the ongoing development of LED UV systems, printers can expect even greater efficiency, sustainability, and performance. Embracing UV curing is a strategic move for any print business aiming to deliver high-quality, long-lasting printed products.