The printing industry is in constant flux, adapting to new technologies that enhance efficiency, quality, and environmental performance. Among these advancements, LED UV curing systems have emerged as a pivotal technology, particularly within digital and hybrid printing applications. Their integration is reshaping how labels, flexible packaging, and various other printed materials are produced, offering compelling advantages over traditional curing methods.

Understanding UV Curing Technology

At its core, UV curing involves using ultraviolet light to instantly polymerize (harden) inks, coatings, and adhesives. This process is significantly faster than conventional methods, which rely on heat or solvent evaporation. Traditional UV curing lamps, often mercury-vapor lamps, emit a broad spectrum of UV light. While effective, they come with drawbacks: high energy consumption, significant heat generation, a shorter lifespan, and the presence of ozone as a byproduct.

The LED UV Revolution

Light Emitting Diodes (LEDs) have revolutionized UV curing. Unlike traditional lamps, LEDs emit UV light at specific wavelengths, typically in the UVA range (365 nm, 395 nm, 405 nm). This specificity offers several key benefits. Firstly, it allows for more targeted curing of specially formulated UV inks and coatings, leading to better performance. Secondly, LEDs generate minimal heat, drastically reducing the thermal load on the substrate. This is particularly beneficial for heat-sensitive materials like thin films and certain plastics used in label and packaging applications.

Advantages in Narrow Web Printing

Narrow web printing, the backbone of label and flexible packaging production, has been a primary beneficiary of LED UV technology. For narrow web presses, speed and efficiency are paramount. LED UV systems enable faster printing speeds because the curing is instantaneous and does not require a warm-up period or cool-down time. This translates to higher throughput and reduced production bottlenecks.

Moreover, the low heat output of LEDs is a game-changer for narrow web applications. Many label stocks and films are sensitive to heat, which can cause distortion, warping, or affect adhesive properties. LED UV curing minimizes this risk, allowing printers to work with a wider range of substrates without compromising quality or material integrity. This expands the creative and functional possibilities for label designers and manufacturers.

Impact on Flexographic Printing

Flexographic printing, widely used for labels and packaging, has also seen significant integration of LED UV technology. Traditional flexo presses often used mercury lamps or hot air drying. The transition to LED UV offers a more sustainable and efficient solution. The precise wavelength control of LEDs allows for excellent cure speeds and adhesion on various substrates, including films, foils, and papers.

The reduced energy consumption of LED systems is another major draw for flexo printers. Compared to mercury lamps, LEDs consume considerably less power, leading to substantial cost savings on electricity bills. Furthermore, their long operational life means less frequent lamp replacements, reducing maintenance costs and downtime. The absence of ozone production also contributes to a safer and more environmentally friendly working environment, often eliminating the need for costly exhaust systems.

Enhancing Digital Printing Capabilities

Digital printing, with its inherent flexibility and on-demand capabilities, benefits immensely from LED UV curing. Many digital printing technologies, such as inkjet, rely on UV-curable inks. LED UV curing ensures these inks solidify instantly as they are deposited, preventing ink spread and maintaining sharp image quality. This is crucial for high-resolution graphics and detailed text often required in label and packaging printing.

The low heat from LEDs is also critical for digital presses. Many digital printing components are sensitive to heat, and substrate temperature must be carefully controlled. LED curing’s minimal thermal impact allows digital presses to achieve higher speeds and print on a broader array of materials without concerns about heat-induced damage or deformation. This opens up new markets for digital printers, enabling them to produce high-quality, durable prints on plastics, synthetics, and even delicate papers.

The Rise of Hybrid Presses

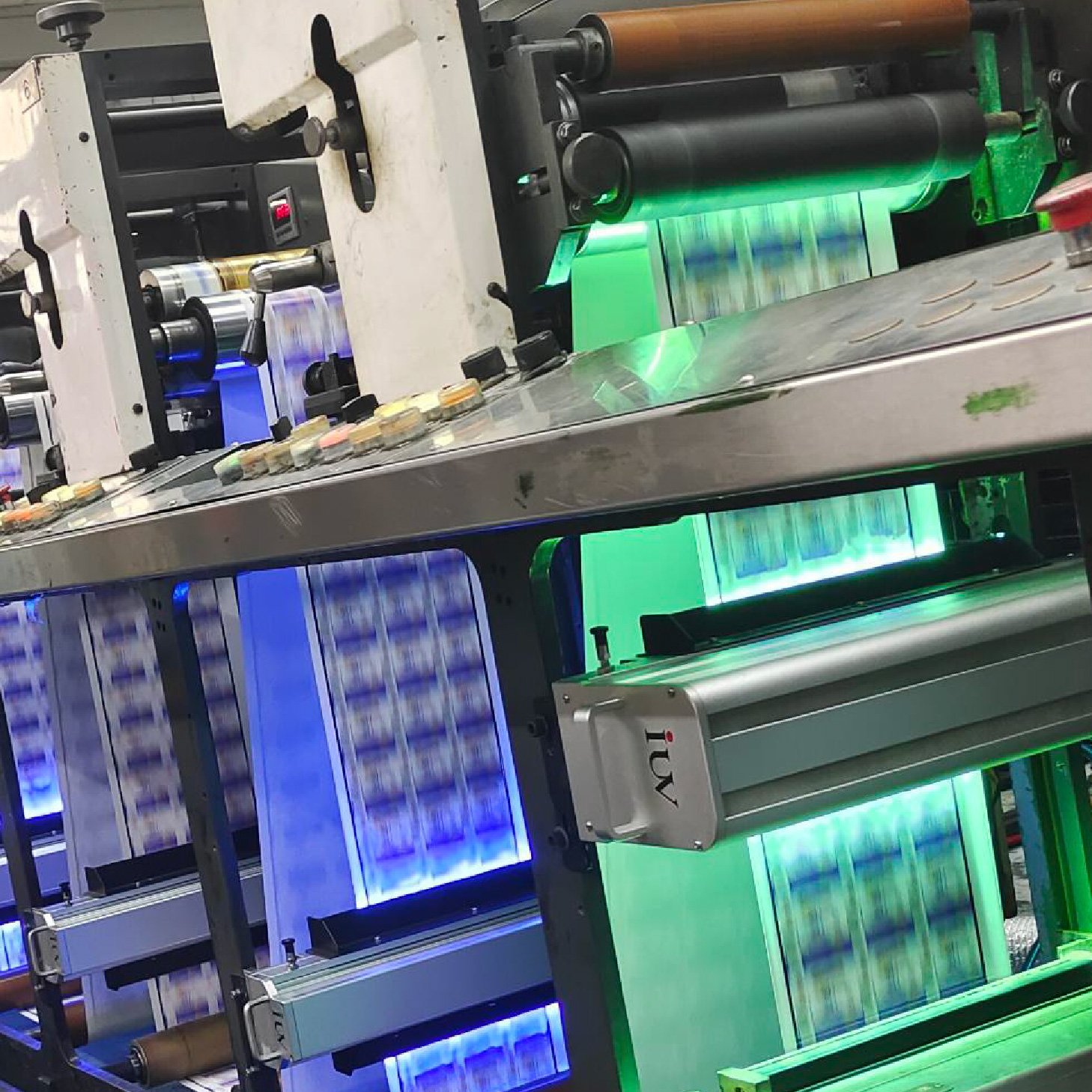

Hybrid presses, which combine different printing technologies (e.g., flexo, offset, digital, screen) on a single platform, are becoming increasingly popular. LED UV curing is an indispensable component of these sophisticated machines. Its ability to integrate seamlessly with various printing methods and its rapid curing capabilities make it ideal for multi-process workflows.

In a hybrid setup, a label or packaging converter might print with flexo, then add digital variable data, and finally apply a protective coating, all within the same press line. LED UV curing stations placed between these different units ensure that each layer is instantly cured, preventing ink transfer and maintaining the integrity of each printing step. This enables complex, high-value products to be produced efficiently in a single pass, significantly reducing waste and lead times.

Substrate Compatibility and Material Science

The compatibility of LED UV curing with a diverse range of substrates is a key factor in its widespread adoption. While traditional UV systems could sometimes cause issues with heat-sensitive materials, LED UV’s cool curing is far more forgiving. This allows printers to confidently use thinner films, recycled content, and materials with specific functional coatings.

The formulation of UV-curable inks and coatings is also evolving to optimize performance with LED UV systems. Manufacturers are developing inks that cure efficiently at the specific wavelengths emitted by LEDs, ensuring excellent adhesion, scratch resistance, and color vibrancy. This symbiotic relationship between LED technology and ink chemistry is driving innovation in print quality and durability.

Environmental and Economic Considerations

Beyond performance, the environmental and economic benefits of LED UV curing are substantial. Reduced energy consumption directly translates to lower operational costs. The elimination of ozone and volatile organic compounds (VOCs) associated with solvent-based inks creates a healthier working environment and reduces the need for expensive fume extraction systems.

The longevity of LED lamps also contributes to cost savings and reduced waste compared to the frequent replacement of mercury lamps. This lower maintenance burden and fewer consumable replacements enhance the overall economic viability of adopting LED UV technology.

Future Outlook

The trajectory of LED UV curing systems in digital and hybrid presses points towards continued growth and innovation. As the technology matures and costs decrease, we can expect even wider adoption across all segments of the printing industry, from narrow web labels to wider format commercial and packaging applications.

The development of new LED emitter technologies, offering wider wavelength options and even higher power output, will further expand the possibilities for curing challenging inks and coatings. Continued advancements in ink and coating formulations specifically designed for LED UV will ensure that printers can meet the ever-increasing demands for quality, speed, and sustainability. The integration of LED UV curing is not just a trend; it is a fundamental shift in how high-quality, efficient, and environmentally responsible printing is achieved.