The printing industry is constantly evolving, and a significant part of this transformation is happening in the realm of UV curing. As businesses seek faster, more efficient, and environmentally friendly printing solutions, UV curing systems are at the forefront of innovation. Let’s explore the exciting trends shaping the future of this technology.

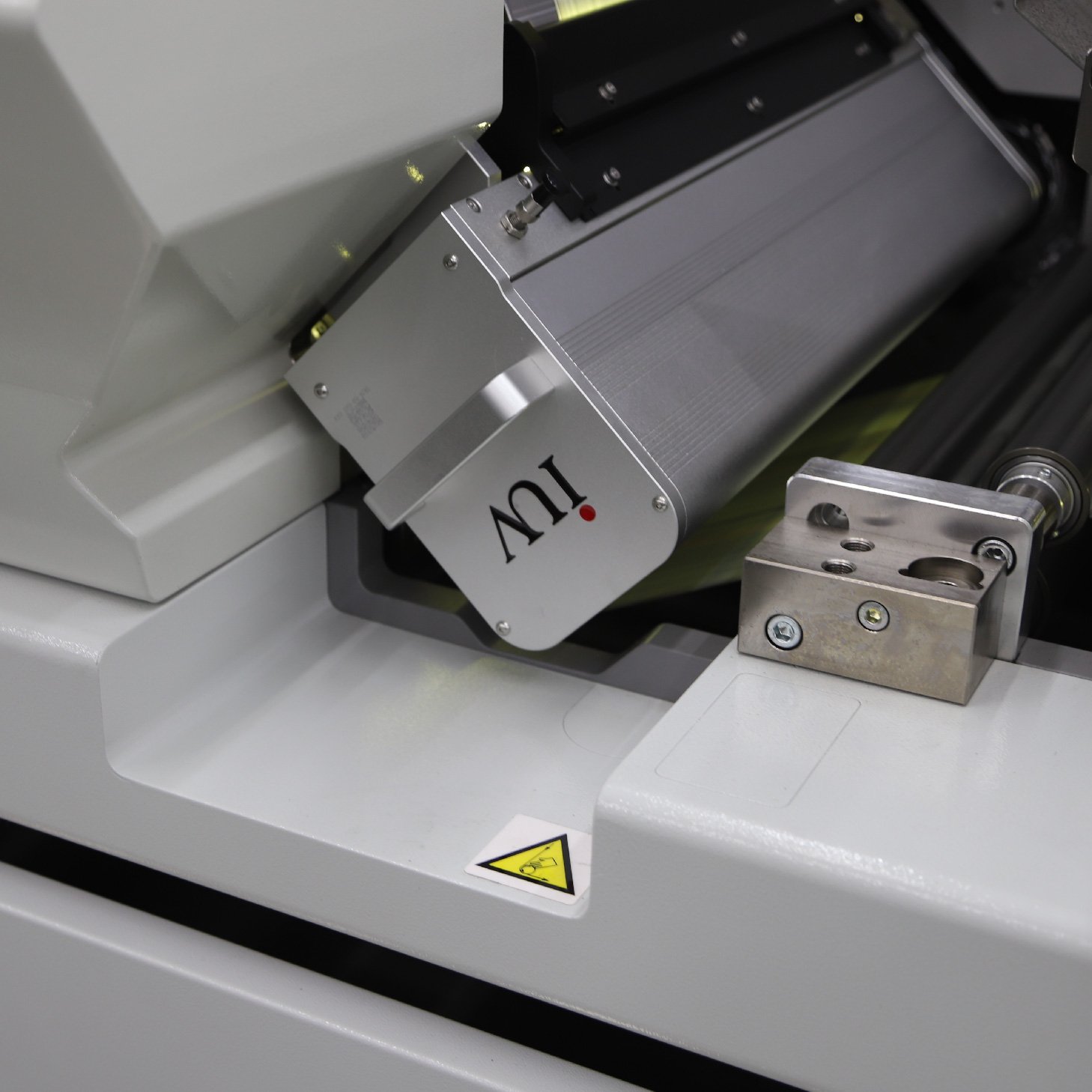

One of the most prominent shifts is the move towards LED UV curing. Traditional mercury lamp UV systems have long been the standard. However, LED technology offers a compelling alternative. LEDs consume significantly less energy, leading to substantial cost savings on electricity bills. They also generate less heat, which is a major advantage for heat-sensitive substrates commonly used in label printing. This reduced heat also means less wear and tear on printing equipment.

Furthermore, LED UV lamps have a much longer lifespan than mercury lamps. This translates to less downtime for replacements and maintenance. The precise control over wavelength offered by LEDs also allows for more tailored curing processes. This means printers can achieve optimal results with a wider range of inks and coatings, ensuring superior adhesion and durability.

In the world of narrow web printing, particularly for labels and packaging, the benefits of LED UV curing are particularly pronounced. Narrow web printers often deal with high-speed production runs and diverse materials. The instant on/off capability of LEDs is a game-changer for job changeovers. Printers can switch between different jobs without the long warm-up and cool-down periods associated with mercury lamps. This agility is crucial for meeting the demands of a fast-paced market.

The environmental aspect of LED UV curing is another major draw. Mercury lamps contain hazardous materials. LEDs, on the other hand, are mercury-free and generate less ozone. This aligns with the growing global emphasis on sustainability and eco-friendly manufacturing practices. As brand owners increasingly prioritize environmentally responsible supply chains, printers adopting LED UV technology gain a competitive edge.

Flexographic printing is another area where UV curing plays a pivotal role. Flexo printing is widely used for packaging, labels, and flexible films. The speed and efficiency of UV-cured inks in flexo processes are essential for high-volume production. With LED UV, flexo printers can achieve even faster speeds and maintain excellent print quality. The reduced heat also prevents substrate distortion, which is a common challenge with certain flexible materials.

Offset printing, or sheetfed and web offset, is also benefiting from advancements in UV curing. While traditionally more reliant on heatset or conventional drying, UV curing is gaining traction. This is especially true for applications requiring immediate post-press handling or high-gloss finishes. The precise control and efficiency of modern UV systems, including LEDs, are making them a more attractive option for offset printers looking to expand their capabilities and reduce turnaround times.

The development of new ink and coating formulations is also intrinsically linked to the evolution of UV curing. As curing technologies advance, so do the materials applied. We are seeing the development of low-migration UV inks, which are critical for food packaging applications. These inks ensure that no harmful substances transfer from the printed material to the food. The precise control offered by LED UV systems is instrumental in achieving the complete curing of these specialized inks, guaranteeing safety and compliance.

Beyond standard inks, UV-curable coatings are enabling printers to achieve unique tactile effects and enhanced durability. Think of soft-touch finishes, high-gloss varnishes, or textured patterns. These special effects can elevate the perceived value of printed products, from premium labels to sophisticated packaging. The ability of LED UV to cure these thicker, more complex coatings efficiently is a significant advantage.

The integration of UV curing systems with digital printing technologies is another exciting frontier. While digital printing offers immense flexibility and personalization, achieving fast and durable curing can be a challenge. LED UV systems are well-suited for integration into digital presses, providing the rapid curing needed for high-speed digital workflows. This synergy is paving the way for on-demand printing with exceptional quality and finish.

Looking ahead, expect to see even more sophisticated UV curing solutions. This includes advancements in spectral control, allowing for even finer tuning of the curing process for different ink chemistries. We’ll also likely see improved energy efficiency and greater integration with print workflow automation. The focus will remain on delivering faster, more sustainable, and higher-quality printing outcomes across all sectors of the industry.

The future of UV curing systems in printing is undeniably bright. The shift towards LED technology, coupled with ongoing innovations in inks, coatings, and integration with digital workflows, promises to redefine what’s possible in the printing world. Printers who embrace these trends will be well-positioned to thrive in the years to come.