The world of narrow-web printing is undergoing a significant transformation, driven by demands for greater efficiency, sustainability, and enhanced print quality. At the forefront of this evolution is UV LED curing technology, a powerful innovation that is reshaping how labels and packaging are produced. This article delves into the capabilities and advantages of UV LED curing within the context of narrow-web printing, exploring its impact on flexographic and offset printing processes.

Understanding Narrow-Web Printing

Narrow-web printing typically refers to printing on substrates that are less than 20 inches wide. This category encompasses a vast range of applications, primarily labels and flexible packaging. The narrow format is ideal for producing high volumes of specialized products efficiently. Traditional methods in this sector have relied on heat or UV lamp curing, each with its own set of limitations.

The Rise of UV LED Curing Technology

UV LED curing utilizes light-emitting diodes (LEDs) to generate ultraviolet (UV) light. This UV light initiates a photochemical process that instantly cures or dries ink, coatings, and adhesives. Unlike conventional UV lamp systems that emit a broad spectrum of light and generate significant heat, UV LEDs emit a narrow band of UV light at specific wavelengths. This targeted approach offers a multitude of benefits for narrow-web printing operations.

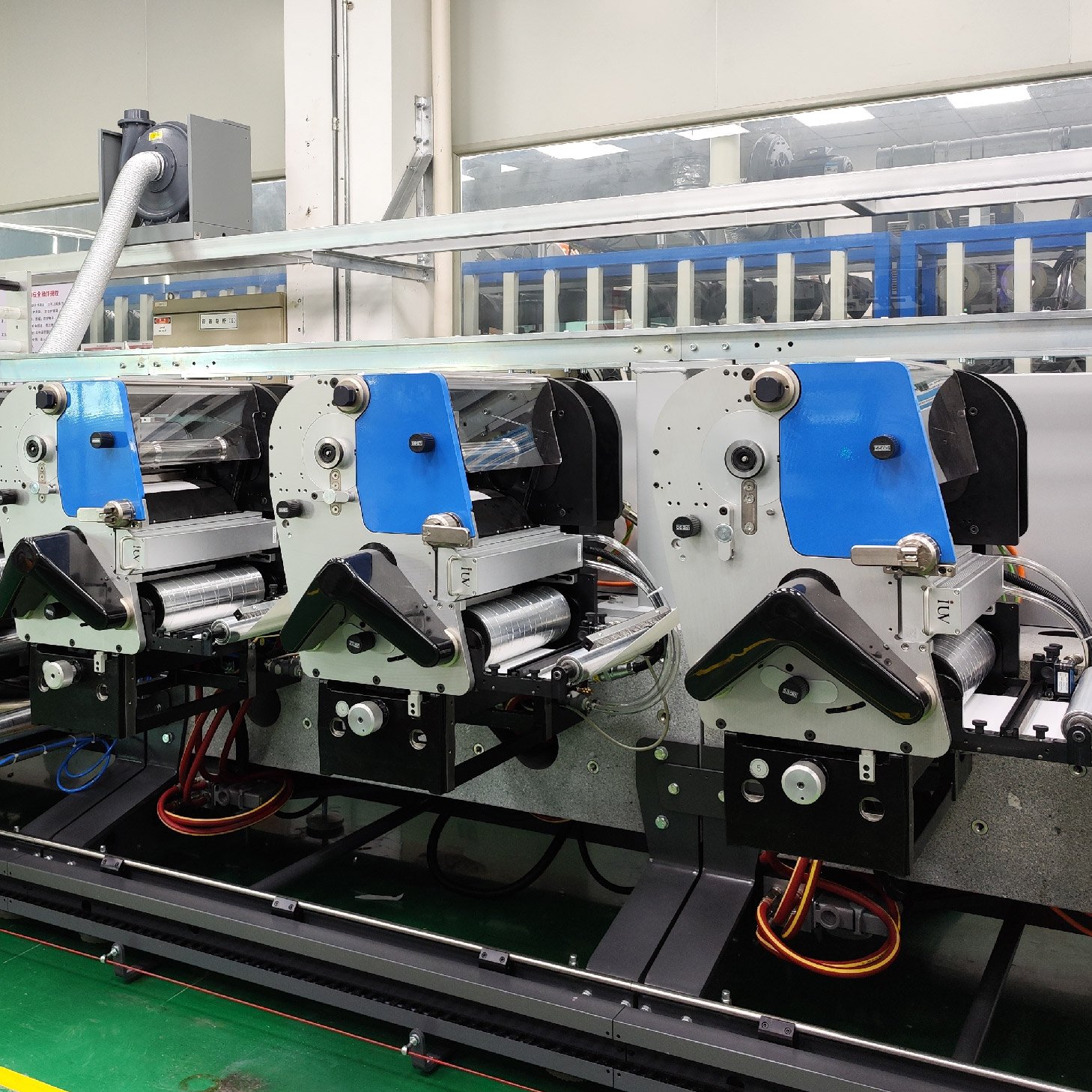

UV LED Curing in Flexographic Printing

Flexographic printing remains a dominant force in narrow-web label and packaging production. The flexibility of flexo, combined with the advancements in UV LED curing, creates a compelling synergy.

- Instant Curing for Higher Speeds: UV LED curing provides immediate drying of inks and coatings. This allows flexographic presses to run at significantly higher speeds without the risk of ink smudging or offsetting. Printers can achieve greater throughput and meet demanding production schedules.

- Enhanced Ink Adhesion and Durability: The precise wavelengths emitted by UV LEDs promote excellent adhesion of specialized UV-curable inks to a wide variety of substrates. This results in prints that are highly resistant to scratching, abrasion, and chemical exposure, crucial for durable labels and packaging.

- Reduced Waste and Setup Time: The instant nature of UV LED curing means less waiting time between print stations and for finished rolls. This translates to quicker job setups and reduced waste during the printing process, contributing to overall cost savings.

- Improved Color Brilliance: UV LED curing enables the use of high-opacity white inks and vibrant color formulations that cure effectively without excessive heat. This allows for superior color saturation and visual impact on the final printed product.

UV LED Curing in Offset Printing

While flexography is prevalent, offset printing also plays a role in certain narrow-web applications, particularly for high-volume, high-definition labels. UV LED curing is equally transformative in this domain.

- Substrate Versatility: Offset printing traditionally requires more absorbent substrates. However, UV LED curing allows for the use of non-absorbent materials like plastic films, which are common in packaging. The instant curing prevents ink from migrating or smudging on these challenging surfaces.

- Consistent Quality: The controlled output of UV LEDs ensures consistent curing from the first print to the last. This eliminates variations in gloss and finish that can sometimes occur with older curing technologies, leading to a more uniform and professional appearance.

- Reduced Heat Load: Offset printing presses can generate considerable heat. UV LED curing systems produce minimal heat, which is a significant advantage. This protects heat-sensitive substrates and allows for more comfortable working conditions within the print shop.

- Environmental Benefits: UV LED curing systems are more energy-efficient than traditional UV lamps. They consume less power, leading to lower electricity bills and a reduced carbon footprint, aligning with growing sustainability initiatives in the packaging industry.

Key Advantages of UV LED Curing in Narrow-Web Applications

The benefits of integrating UV LED curing into narrow-web printing extend across multiple operational and environmental fronts.

- Energy Efficiency: UV LEDs consume substantially less energy compared to conventional mercury vapor lamps. They also have a longer lifespan, reducing the need for frequent replacements and associated disposal.

- Reduced Heat Emission: The minimal heat output from UV LEDs prevents substrate distortion and allows for the printing on a wider range of materials, including thin films and heat-sensitive plastics. This opens up new creative possibilities for designers and brand owners.

- Instant Curing: Immediate curing means no waiting for inks to dry. This enables faster press speeds, reduced waste from smudging, and quicker turnaround times from job start to finish.

- Environmental Friendliness: UV LED systems do not contain mercury, making them a more environmentally responsible choice. Their lower energy consumption also contributes to a reduced carbon footprint.

- Compact Footprint: UV LED curing units are typically more compact than traditional UV lamp systems, making them easier to integrate into existing narrow-web presses without requiring significant modifications.

- Consistent Performance: LEDs offer stable and consistent UV output throughout their lifespan, ensuring reliable curing performance job after job. This leads to predictable print quality and fewer production issues.

- Odorless Prints: UV LED-cured inks and coatings generally produce odorless prints, which is particularly important for food packaging and other sensitive applications.

Overcoming Challenges and Future Trends

While UV LED curing offers significant advantages, there are considerations for adoption. Initial investment costs can be higher than traditional systems. However, the long-term savings in energy, reduced waste, and increased throughput often justify the upfront expenditure.

The technology is continually evolving. Newer UV LED systems offer wider wavelength options and higher power densities, allowing for even faster curing speeds and the use of a broader spectrum of inks and coatings. The development of low-migration UV inks is also crucial for food packaging applications, ensuring that printed materials are safe for direct or indirect contact with food.

The trend towards shorter print runs and greater customization in labels and packaging further amplifies the benefits of UV LED curing. Its speed, efficiency, and ability to handle a diverse range of substrates make it an ideal solution for this dynamic market. As sustainability becomes an even greater imperative, the energy efficiency and mercury-free nature of UV LED technology will continue to drive its adoption.

Conclusion

UV LED curing represents a pivotal advancement in narrow-web printing for labels and packaging. Its ability to enhance speed, improve print quality, expand substrate capabilities, and offer significant environmental and energy efficiencies positions it as the technology of choice for forward-thinking printers. By embracing UV LED curing, businesses can gain a competitive edge, meet evolving market demands, and contribute to a more sustainable printing future.