The Evolution of LED UV Curing Systems in the Printing Industry

The printing industry is constantly evolving. New technologies emerge to improve quality and efficiency. LED UV curing systems represent a significant leap forward. These systems have revolutionized how inks and coatings are dried. This technology offers substantial benefits across various printing applications.

What is UV Curing?

UV curing uses ultraviolet light. This light initiates a photochemical process. It instantly hardens inks and coatings. Traditional drying methods often involve heat. Heat can damage sensitive substrates. It also consumes more energy. UV curing offers a faster, more efficient alternative.

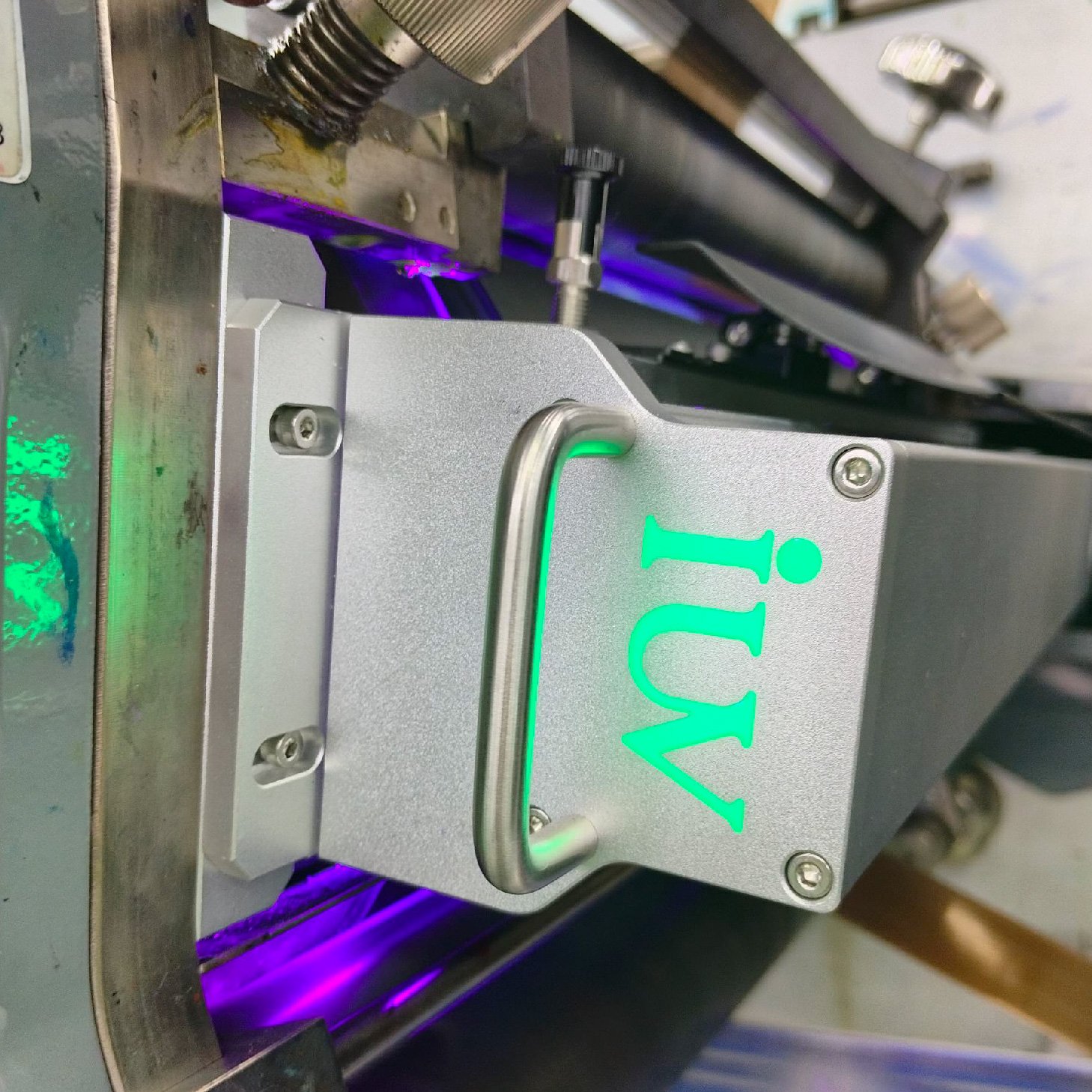

The Rise of LED UV Technology

For years, mercury vapor lamps dominated UV curing. These lamps have drawbacks. They generate a lot of heat. Their lifespan is limited. They also contain hazardous materials. Light Emitting Diodes (LEDs) offer a superior solution. LED UV systems use specific wavelengths of light. This precise control is a major advantage.

Benefits of LED UV Curing

LED UV systems provide numerous advantages. They are highly energy-efficient. They consume significantly less power than mercury lamps. This translates to lower operating costs. Their lifespan is much longer, often tens of thousands of hours. This reduces maintenance and replacement expenses.

Another key benefit is instant on/off capability. This saves energy. It also prevents heat buildup on the substrate. This is crucial for heat-sensitive materials. Think about delicate films or thin papers. LED UV avoids warping or damage.

LED UV systems also offer better wavelength control. This allows for optimized curing of specific inks. This improves print quality and durability. Environmental impact is also reduced. There are no hazardous mercury vapors. This makes for a safer working environment.

Impact on Narrow Web Printing

Narrow web printing is ideal for labels and packaging. LED UV curing is a perfect fit here. Many narrow web presses are now equipped with LED UV units. This allows printers to achieve faster production speeds. They can also run a wider variety of substrates.

The precise control of LED UV is beneficial for complex label designs. It ensures vibrant colors and sharp details. It also enables immediate handling of printed labels. This speeds up the finishing process. Think about die-cutting or slitting. These can happen right after printing.

Flexographic Printing and LED UV

Flexographic printing is widely used for packaging and labels. Integrating LED UV curing into flexo presses has transformed the sector. Flexo printers can now use faster drying inks. This means higher press speeds are achievable. The ability to cure on diverse substrates is a boon. Plastic films, foils, and textured papers are now easily printed.

The reduced heat from LED UV is critical for thin film applications. It prevents film distortion. This ensures dimensional stability of the final product. It also allows for printing on recycled or compostable materials. These often have lower heat tolerances.

Offset Printing Applications

Offset printing also benefits from LED UV. Sheetfed and web offset presses can be retrofitted. This allows for faster turnaround times. It also opens up new substrate possibilities. Previously, heat-set web offset was required for many jobs. LED UV offers an alternative.

Printers can now achieve high-quality finishes. They can use special effect inks. These inks require precise curing. LED UV provides this precision. The instant drying means no waiting. This is a significant advantage for short-run jobs. It also reduces the need for inter-deck drying units. This saves space and energy.

Label Printing with LED UV

Label printing is a prime area for LED UV adoption. Labels often require durability and vibrant aesthetics. LED UV inks offer excellent scratch and chemical resistance. This is vital for product labels exposed to harsh conditions.

The ability to print on a wide range of label materials is key. This includes clear films, paper, and specialty substrates. LED UV ensures perfect adhesion and consistent print quality. For high-volume label production, the speed and efficiency of LED UV are unmatched.

The Future is Bright with LED UV

The evolution of LED UV curing systems is ongoing. Manufacturers are continually improving the technology. We can expect even greater efficiency and versatility. Further advancements in LED chip technology will deliver more power. New ink formulations will also emerge. These will be specifically designed for LED UV curing.

The environmental benefits are increasingly important. Regulations are becoming stricter. LED UV offers a sustainable printing solution. Its energy efficiency and lack of hazardous materials align with green initiatives.

As the printing industry embraces digital transformation, LED UV remains a cornerstone technology. It enables faster, higher-quality, and more sustainable printing practices. Its widespread adoption across narrow web, flexo, and offset printing demonstrates its undeniable value. The future of printing is undeniably brighter with LED UV.