Flexographic printing, commonly known as flexo, is a widely used technique in the packaging and label industry. As demand for more sustainable and efficient production methods increases, printers are exploring new technologies to enhance their operations. One such innovation that has gained significant attention is LED UV curing. The transition to LED UV curing in flexo printing offers various benefits, ranging from cost savings to environmental impact reductions. This article explores the economic implications of switching to LED UV curing and examines how it is revolutionizing the flexographic printing industry.

Understanding LED UV Curing in Flexo Printing

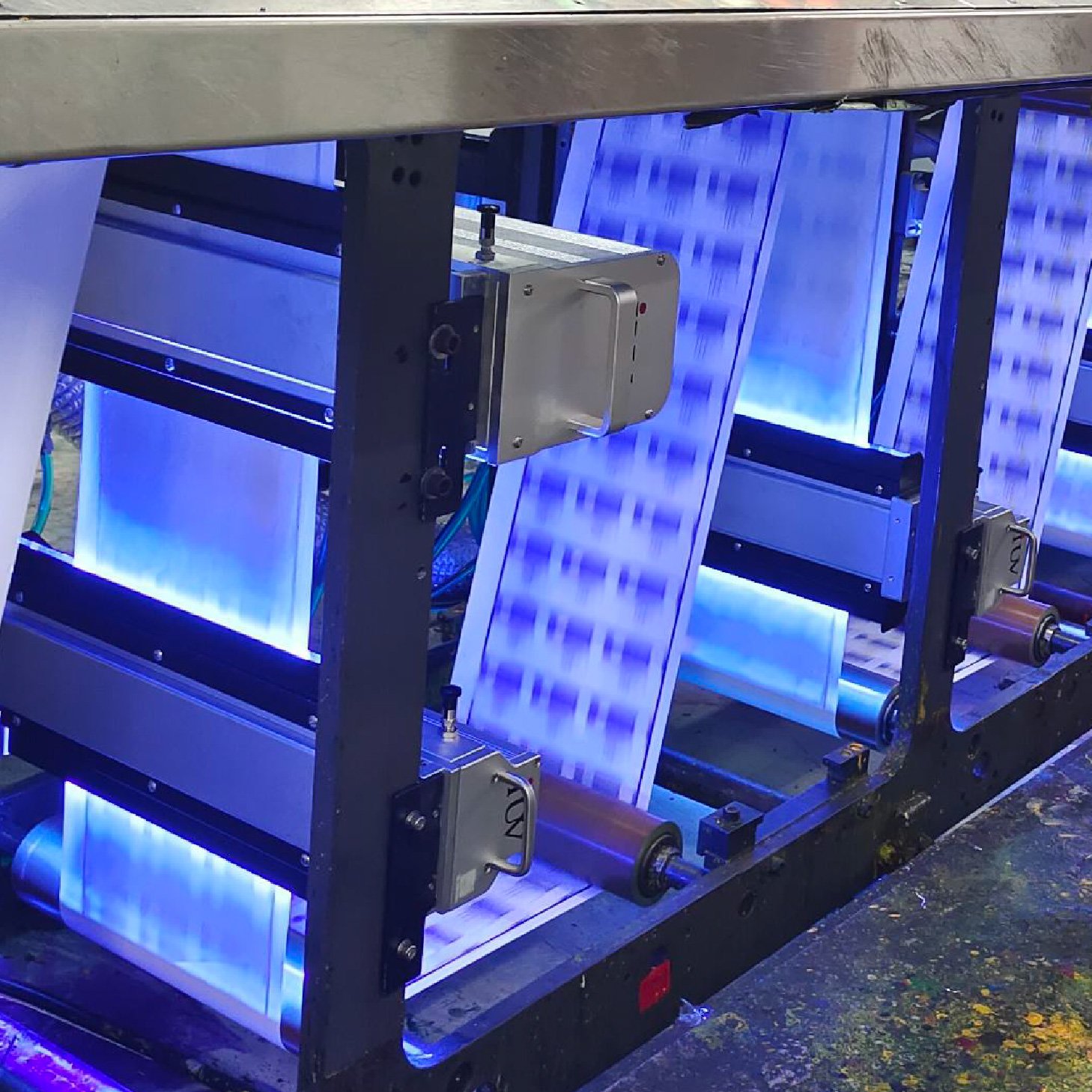

Before diving into the economic advantages, it’s important to understand what LED UV curing is and how it works within the context of flexo printing. Flexo printing uses flexible photopolymer plates (often referred to as “flexo plates”) that are inked and then pressed onto a substrate. The ink is typically cured using UV light to quickly dry it, allowing for faster print speeds.

Traditional UV curing relies on mercury vapor lamps, which consume a lot of energy and require frequent replacement. In contrast, LED UV curing uses light-emitting diodes (LEDs) to cure the ink. LEDs are energy-efficient, long-lasting, and produce less heat, which offers several operational and economic advantages over traditional UV curing systems.

Key Benefits of LED UV Curing in Flexo Printing

1. Lower Energy Consumption

One of the most significant benefits of switching to LED UV curing is the drastic reduction in energy consumption. LED lamps consume much less power than mercury vapor lamps, often by as much as 50% to 70%. This energy efficiency leads to lower electricity bills and a more sustainable operation. Over time, these savings can add up, especially for high-volume printing businesses that run equipment continuously throughout the day.

Additionally, LED UV systems produce little heat compared to traditional UV lamps, reducing the need for costly air conditioning systems to cool the printing environment. This further contributes to energy savings and lowers operational costs.

2. Longer Lamp Lifespan

LED UV lamps have a significantly longer lifespan compared to mercury vapor lamps. While traditional UV lamps may need to be replaced every 1,000 to 2,000 hours of operation, LED lamps can last up to 20,000 hours or more. This longer lifespan results in fewer replacements and lower maintenance costs, which is a major economic advantage for printers who rely on their equipment for high-volume production.

Moreover, LED UV systems typically require less frequent servicing, leading to reduced downtime and better overall equipment utilization. This can have a direct impact on productivity and profitability.

3. Improved Print Quality and Faster Curing Times

LED UV curing provides faster curing times compared to traditional UV methods. The immediate curing of the ink allows for faster production speeds, reducing the time needed for each print job. As a result, printers can achieve higher throughput, completing more jobs in a given period.

Faster curing times also improve the overall quality of the print. With LED UV curing, ink is cured instantly, preventing the risk of smudging or other quality issues associated with slower drying processes. This ensures that printed materials are of high quality, which can translate into increased customer satisfaction and repeat business.

4. Reduced Waste and Improved Sustainability

The sustainability aspect of LED UV curing cannot be overstated. LED systems produce less heat, which reduces the likelihood of substrate warping or distortion, a common issue in traditional UV curing. This leads to fewer defective prints and less material waste.

Additionally, LED UV systems do not contain hazardous materials like mercury, which is a significant environmental concern with mercury vapor lamps. The reduced environmental footprint of LED curing aligns with the growing demand for more eco-friendly production practices in the printing industry. For businesses seeking to improve their sustainability efforts and reduce their carbon footprint, switching to LED UV curing offers a clear advantage.

5. Cost Savings on Ink and Substrates

LED UV curing also has a positive impact on ink usage. The rapid curing process means that ink does not have time to evaporate or spread beyond the desired area, leading to more efficient use of ink. This translates into lower ink costs per print job, which can be especially important for high-volume flexo printers.

Furthermore, the reduced heat generated by LED UV curing means that sensitive substrates, such as thin films or plastic materials, are less likely to be damaged during the curing process. This opens up new possibilities for printing on a wider range of materials, without the added cost of using specialized substrates or dealing with print defects due to heat distortion.

Economic Considerations in Making the Switch

Switching to LED UV curing is a major investment, and printers must weigh the upfront costs against the long-term savings. The initial cost of purchasing LED UV systems can be higher than traditional UV curing systems, but these costs can be recouped over time through savings on energy, lamp replacements, and maintenance.

To determine whether the switch makes economic sense, printers should consider their production volumes and the frequency of lamp replacements. For high-volume operations, the savings in energy costs and the reduction in maintenance expenses can quickly offset the higher initial investment. Additionally, printers who frequently work with heat-sensitive materials or require high-quality print results may find that the benefits of LED UV curing justify the upfront cost.

Moreover, LED UV systems are becoming increasingly affordable as the technology matures and becomes more widely adopted. As demand for LED UV systems grows, competition among manufacturers is driving prices down, making it more accessible for small and medium-sized printers to make the transition.

Conclusion: Is LED UV Curing Worth the Investment?

In conclusion, the economics of switching to LED UV curing in flexo printing are compelling. The energy savings, longer lamp lifespan, faster curing times, and improved sustainability all contribute to significant cost reductions over time. While the initial investment may be higher than traditional UV curing systems, the long-term benefits far outweigh the costs for many printers.

By adopting LED UV curing, flexo printers can improve their operational efficiency, enhance print quality, reduce waste, and lower their environmental impact—all while enjoying a stronger bottom line. For businesses looking to stay competitive in a rapidly evolving industry, transitioning to LED UV curing offers a smart economic strategy that aligns with both economic and environmental goals.

As LED UV technology continues to evolve, it is likely that more printers will adopt this solution as a standard for their operations. The future of flexo printing is undeniably heading in the direction of LED UV curing, and those who make the switch will reap the rewards for years to come.