The printing industry is in constant evolution. Staying competitive requires embracing new technologies. Among these, LED UV curing stands out. It offers significant benefits over traditional methods. For printers, especially those in narrow web, flexographic, and offset sectors, modular and scalable LED UV systems are a game-changer. These systems provide flexibility. They also offer cost-effectiveness and enhanced performance.

Understanding LED UV Curing Technology

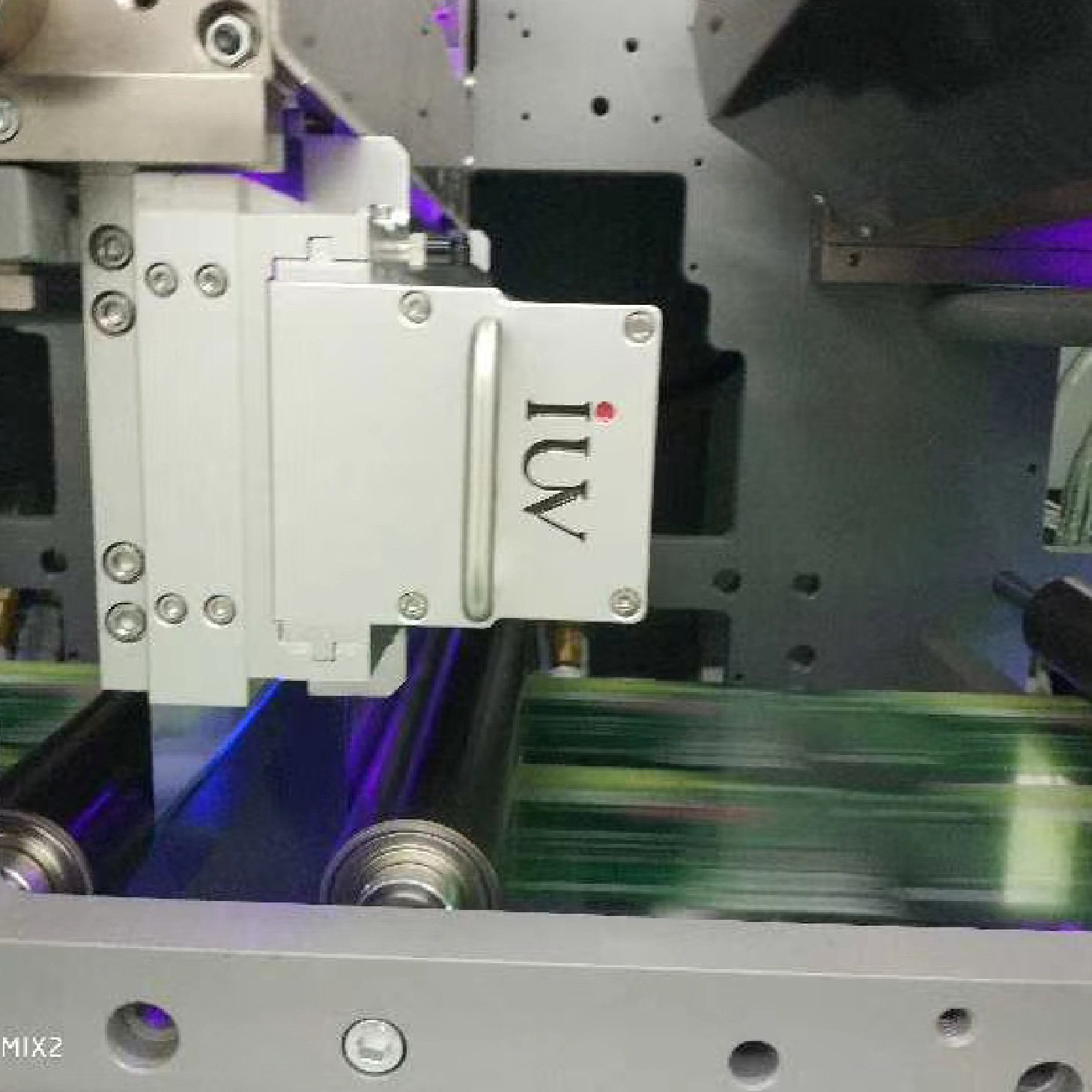

Traditional UV curing often uses mercury vapor lamps. These lamps generate heat and ozone. They also have a shorter lifespan. LED UV curing, on the other hand, uses light-emitting diodes. LEDs emit light at specific wavelengths. This is highly efficient for curing UV inks and coatings. The process is faster. It requires less energy. It also produces less waste. This leads to a more sustainable and productive printing operation.

The Rise of Modular and Scalable Systems

The beauty of modular LED UV curing systems lies in their adaptability. Printers can start with a basic setup. They can then expand it as their needs grow. This “pay-as-you-grow” model is incredibly attractive. It reduces initial investment costs. It also allows businesses to scale their operations without major disruptions. Scalability means the system can grow with your business. You are not limited by a fixed configuration.

Key Advantages for Narrow Web Printers

Narrow web printing, common for labels and flexible packaging, benefits immensely.

- Faster Curing Speeds: LED UV allows for rapid curing. This is vital for high-speed printing presses. It means faster throughput. Less time is spent waiting for ink to dry.

- Reduced Heat on Substrate: Many narrow web substrates are sensitive to heat. Traditional UV lamps can cause warping or damage. LED UV systems emit very little heat. This protects delicate materials like thin films and plastics.

- Instant On/Off: LEDs turn on and off instantly. This saves energy. It also reduces wear and tear on the lamps. There is no warm-up time needed.

- Consistent Performance: LEDs provide a stable UV output. This ensures consistent ink curing. It leads to repeatable high-quality results across print runs.

Enhancements for Flexographic Printing

Flexographic printing, widely used for packaging, also sees significant advantages.

- Improved Ink Adhesion: The precise wavelength output of LEDs promotes better cross-linking of UV inks. This results in superior ink adhesion. It is crucial for durable and high-performance prints.

- Wider Ink Compatibility: Modern LED UV systems work with a broad spectrum of LED-curable inks. This gives flexo printers more creative freedom. They can choose inks tailored to specific applications.

- Lower VOC Emissions: LED UV curing is a low-VOC process. This aligns with increasing environmental regulations. It creates a safer working environment. It also appeals to environmentally conscious brands.

- Extended Press Uptime: The longevity of LED lamps means fewer replacements. This reduces maintenance downtime. Presses stay running longer. Productivity increases.

Benefits for Offset and Sheet-Fed Printers

While often associated with web printing, LED UV curing is increasingly adopted in offset and sheet-fed operations.

- Immediate Handling: Once cured by LED UV, printed sheets can be handled immediately. This eliminates drying delays. It speeds up post-press processes like cutting and folding.

- Varnishing and Coating Excellence: LED UV is perfect for high-gloss or matte varnishes. It provides a durable, protective layer. This enhances the visual appeal of printed materials.

- Print on Diverse Substrates: The low-heat nature of LED UV allows printing on a wider range of materials. This includes plastics, metals, and other non-absorbent surfaces. This opens up new market opportunities.

- Reduced Energy Consumption: Compared to mercury lamps, LED UV systems consume significantly less power. This translates into lower electricity bills. It also contributes to a smaller carbon footprint.

The Power of Modularity and Scalability

Let’s delve deeper into why modularity and scalability are so critical.

- Cost Efficiency: A modular system allows printers to purchase only what they need initially. As their business expands or they take on more demanding jobs, they can add more modules. This avoids over-capitalization. It also ensures the technology investment is always aligned with current needs.

- Future-Proofing: The printing market is dynamic. New inks, substrates, and finishing techniques emerge constantly. A scalable system can be adapted to accommodate these changes. Upgrading or adding modules is often simpler than replacing an entire system.

- Flexibility in Application: Modular designs can often be configured for different printing widths or press speeds. This allows printers to serve a diverse client base. They can handle small runs or large production volumes with the same core technology.

- Integration Ease: Modern modular LED UV systems are designed for easy integration. They can often be retrofitted onto existing printing presses. This minimizes disruption to ongoing operations.

Addressing Common Concerns

Some printers might have reservations about adopting new technology.

- Initial Investment: While the upfront cost can seem higher than traditional UV, the long-term savings are substantial. Lower energy bills, reduced waste, and increased productivity quickly offset the initial expense.

- Technical Expertise: Reputable manufacturers provide comprehensive training and support. Modern systems are also designed to be user-friendly, reducing the learning curve.

- Ink Availability: The market for LED-curable inks is mature and growing. A wide variety of high-quality inks are readily available for different printing processes and applications.

The Future is LED UV

The advantages of modular and scalable LED UV curing systems are undeniable. For printers focusing on narrow web, flexographic, offset, and other applications, this technology offers a clear path to improved efficiency, reduced costs, and enhanced print quality. The ability to adapt and grow with a modular system ensures that printers can remain competitive in an ever-changing industry. Embracing LED UV is not just about adopting new equipment; it’s about investing in a more sustainable, productive, and profitable future for your printing business.