Thinking about upgrading your printing press? LED curing systems offer a compelling path forward. This isn’t just about new technology; it’s about smarter, more efficient, and more sustainable printing. We’ll explore how retrofitting your existing press with LED UV curing can transform your operations.

The Power of LED UV Curing for Labels

Label printing is a prime area where LED curing shines. Narrow web printers, especially, benefit immensely. Traditional methods often involve long drying tunnels or mercury UV lamps. These consume significant energy and generate heat. LED UV curing, however, is different. It uses specific wavelengths of UV light to instantly cure inks, coatings, and adhesives.

For label printers, this means faster production speeds. You can run your presses at their maximum mechanical limits. No more bottlenecks caused by slow drying. This increased throughput directly translates to higher output and more completed jobs. Think about the competitive edge this gives you in the demanding label market.

Flexographic Printing and LED Compatibility

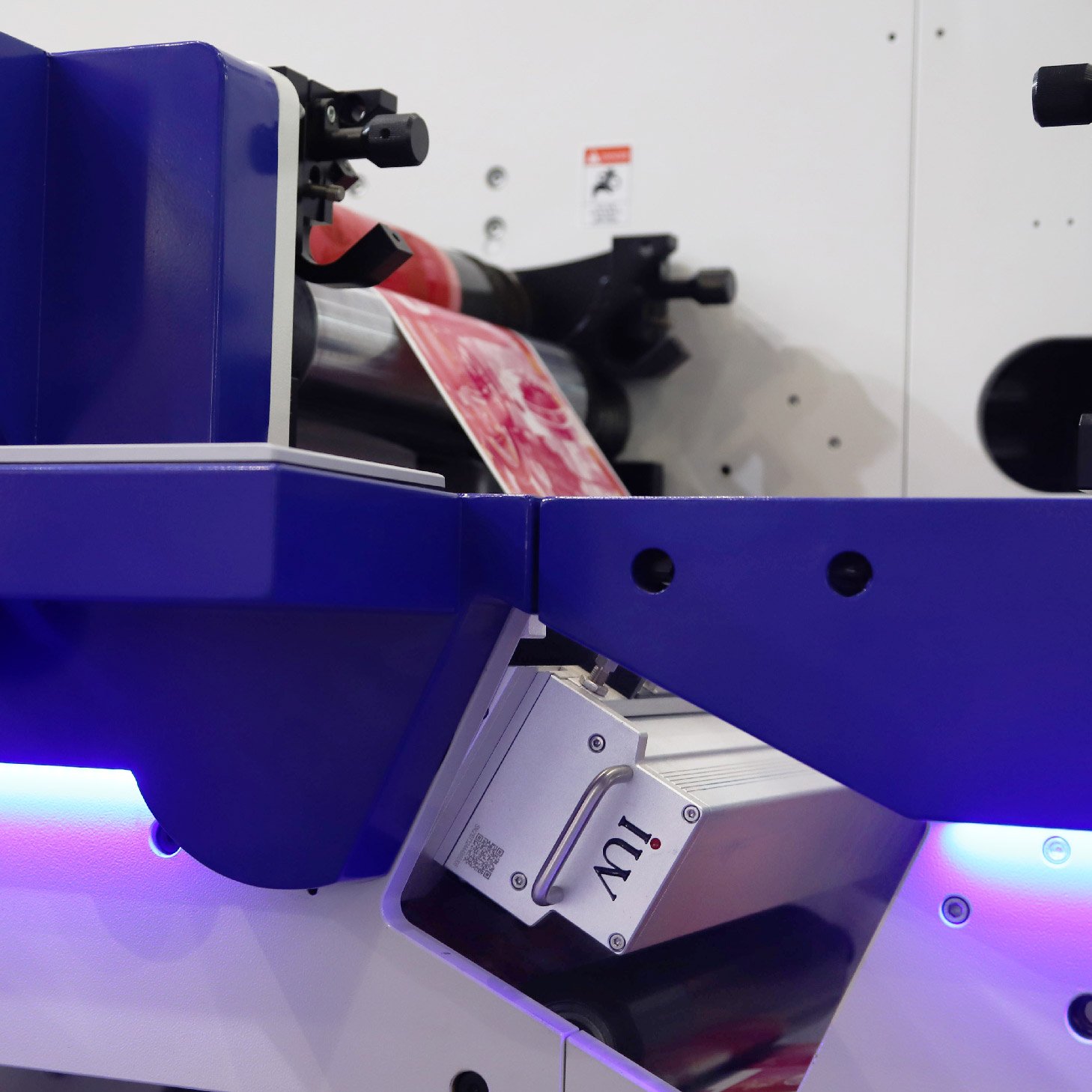

Flexographic printing, or flexo, is widely used for labels and packaging. When you retrofit a flexo press with LED UV curing, you unlock new possibilities. LED systems are more compact than traditional UV units. This makes installation easier, even on older presses. You save valuable press space.

The instant curing capability of LED UV is a game-changer for flexo. It allows for cleaner printing with sharper dot definition. Because the ink cures immediately, there’s less chance of ink spread or smudging. This is critical for high-quality graphics and small text often found on labels.

Furthermore, LED UV inks are formulated to cure effectively under specific LED wavelengths. This means you can achieve excellent adhesion and rub resistance. Your printed labels will look great and hold up to the rigors of product handling and shipping.

Offset Printing’s LED Transformation

Offset printing, especially sheetfed and web offset, also sees major gains with LED curing. Many offset presses are already set up for UV inks. Retrofitting with LED UV systems provides a more energy-efficient and cooler curing solution.

For sheetfed offset, instant curing means faster make-ready times. Sheets can be handled, stacked, and finished immediately after printing. This speeds up the entire post-press process. For web offset, similar to flexo, faster speeds and better print quality are the primary benefits.

The reduced heat output from LED curing is another significant advantage. This is particularly important for heat-sensitive substrates that might warp or degrade under the intense heat of traditional UV lamps. LED curing allows you to print on a wider range of materials, expanding your substrate options.

Narrow Web Printing: The Perfect Match for LED

Narrow web printing, the domain of label and flexible packaging production, is arguably where LED UV curing has made its most profound impact. These presses are designed for high-speed, high-volume production of smaller format jobs.

Retrofitting a narrow web press with LED UV systems is a natural fit. The precise and localized curing of LED light is ideal for the tight tolerances and fast speeds of these machines. You can achieve vibrant colors and durable finishes consistently.

The ability to cure multiple ink layers or special effects like spot coatings instantly is also a major plus. This opens doors for intricate label designs and premium finishes. Think about tactile effects or high-gloss coatings applied in-line. LED makes it possible.

Understanding UV Curing Technology

At its core, UV curing involves using ultraviolet light to initiate a photochemical reaction. This reaction transforms liquid ink, coating, or adhesive into a solid, dry film. Traditional UV curing typically uses mercury vapor lamps. These lamps emit a broad spectrum of UV light.

LED UV curing, on the other hand, uses light-emitting diodes. These diodes are engineered to emit UV light at very specific, narrow wavelengths. The most common wavelengths for UV curing are around 365 nm, 385 nm, 395 nm, and 405 nm. This precision is a key difference.

Because LED systems emit only the necessary wavelengths, they are more energy-efficient. They convert a higher percentage of electrical energy into UV light. They also generate much less heat compared to mercury lamps. This leads to lower operating costs and a more comfortable working environment.

The Benefits of Retrofitting: A Deeper Dive

When you decide to retrofit your printing press with LED UV curing systems, you’re investing in several key areas:

- Energy Efficiency: LED systems consume significantly less power than traditional mercury lamps. This reduces your electricity bills and your carbon footprint.

- Reduced Heat Output: Lower heat means less stress on your press and substrates. You can print on a wider variety of materials, including heat-sensitive plastics and thin papers.

- Instant Curing: Experience immediate ink and coating solidification. This allows for faster production speeds and eliminates the need for cooling systems or long drying lines.

- Increased Durability: LED-cured inks and coatings often offer superior scratch, abrasion, and chemical resistance. This ensures your printed products are long-lasting and maintain their appearance.

- Environmental Advantages: LED systems are mercury-free, making them more environmentally friendly. Their energy efficiency also contributes to a greener operation.

- Longer Lifespan: LED lamps have a much longer operational life than mercury lamps, reducing replacement costs and downtime.

- Improved Print Quality: Achieve sharper dots, better color consistency, and cleaner print definition due to the precise and rapid curing process.

Key Considerations for Retrofitting

Before you make the switch, there are a few things to consider. First, identify the specific needs of your printing operation. What types of jobs do you run most often? What substrates do you use? What are your speed requirements?

Next, consult with manufacturers specializing in LED UV curing systems. They can assess your current press and recommend the best LED solutions. This might involve integrated systems or retrofittable modules.

Ensure your press mechanics can handle the increased speeds that LED curing enables. You may need to consider upgrades to other press components to fully leverage the benefits of LED.

Finally, choose inks, coatings, and adhesives specifically formulated for LED UV curing at your chosen wavelengths. Using the correct consumables is crucial for achieving optimal results.

Retrofitting your printing press with LED UV curing systems is a strategic decision. It’s about modernizing your capabilities, enhancing efficiency, and improving the quality and durability of your printed output. The advantages in speed, energy savings, and material versatility make it a powerful upgrade for any label, flexo, offset, or narrow web printer looking to stay ahead.