Ink migration remains a persistent challenge in the printing industry, particularly within sensitive applications like food packaging and pharmaceuticals. This phenomenon, where ink components transfer from the printed surface to the packaged product, can compromise product safety and brand integrity. Fortunately, advancements in curing technology offer powerful solutions. High-intensity Light Emitting Diode (LED) curing technology has emerged as a transformative force, significantly reducing ink migration risks, especially in narrow web, flexographic, and offset printing processes.

Understanding the Ink Migration Challenge

Ink migration occurs when uncured or incompletely cured ink components migrate through the substrate or over the edges of the printed area. This can be influenced by several factors, including:

- Ink Formulation: The chemical composition of the ink, including the presence of plasticizers, photoinitiators, and other additives, plays a crucial role.

- Substrate Porosity: Highly porous substrates are more susceptible to migration as ink components can penetrate deeper.

- Curing Efficiency: Inadequate curing leaves uncured ink on the surface, increasing the likelihood of migration.

- Environmental Conditions: Temperature, humidity, and contact time with the product can all exacerbate migration.

The consequences of ink migration are severe. For food and pharmaceutical packaging, it can lead to contamination, posing health risks to consumers. This not only results in costly recalls but also severely damages brand reputation. For other applications, ink migration can affect the aesthetic appeal and functional performance of the printed material.

Traditional Curing Methods and Their Limitations

Historically, printing operations have relied on thermal curing and mercury vapor UV lamps. While these methods have served the industry for years, they present distinct limitations when it comes to controlling ink migration:

Thermal Curing: This process uses heat to evaporate solvents from the ink. While effective for certain ink types, it often requires significant energy input and can lead to substrate distortion, especially with heat-sensitive materials common in narrow web applications. Incomplete drying can still leave volatile components that may migrate.

Mercury Vapor UV Lamps: These lamps emit UV radiation across a broad spectrum, initiating polymerization in UV-curable inks. However, they have several drawbacks:

- Energy Inefficiency: Mercury lamps consume considerable power and generate substantial heat, which can affect the printing environment and substrate.

- Ozone Production: The UV output can generate ozone, requiring ventilation systems and posing potential health concerns.

- Component Degradation: The broad spectrum of UV light can sometimes degrade certain ink components or the substrate itself.

- Uneven Curing: Achieving uniform and complete cure across the printed area can be challenging, leaving pockets of uncured ink susceptible to migration.

- Waste and Disposal: Mercury bulbs have a limited lifespan and pose environmental challenges for disposal.

These limitations highlight the need for a more controlled, efficient, and effective curing solution, especially for printers prioritizing food safety and high-quality output.

The Advent of High-Intensity LED Curing Technology

High-intensity LED curing represents a paradigm shift in UV curing. Instead of broad-spectrum mercury lamps, LED systems utilize specific wavelengths of UV light emitted by semiconductor diodes. This targeted approach offers numerous advantages, directly addressing the limitations of traditional methods and providing superior control over ink migration.

Key Advantages of High-Intensity LED Curing:

- Targeted Wavelengths: LED systems can be precisely tuned to specific wavelengths (e.g., 365 nm, 395 nm) that efficiently activate the photoinitiators in UV-curable inks. This targeted energy delivery ensures a more complete and uniform cure.

- Instant On/Off Capability: LEDs can be switched on and off instantaneously. This eliminates the warm-up and cool-down periods associated with mercury lamps, improving press uptime and efficiency. It also means energy is only consumed when curing is actively required.

- Lower Operating Temperatures: LED curing generates significantly less heat compared to mercury lamps. This is critical for printing on heat-sensitive substrates, preventing warping, and maintaining dimensional stability. Reduced heat also contributes to a more stable printing environment.

- Energy Efficiency: LEDs are far more energy-efficient, consuming up to 70-80% less power than traditional mercury systems for equivalent curing output. This translates to substantial operational cost savings.

- Longer Lifespan and Consistency: LED arrays have a much longer operational lifespan (20,000 hours) and maintain their spectral output consistently over time. This reduces downtime for bulb replacements and ensures predictable curing performance batch after batch.

- Reduced Ozone Production: The specific wavelengths emitted by LEDs do not typically produce ozone, eliminating the need for extensive ventilation and improving workplace safety.

- Compact Design: LED lamps are often more compact than mercury lamps, allowing for easier integration into existing narrow web printing presses and finishing lines.

How High-Intensity LED Curing Reduces Ink Migration

The superior performance of high-intensity LED curing directly translates into a significant reduction in ink migration risks through several mechanisms:

- Enhanced Polymerization: The precise and intense UV output from LEDs drives a more complete and rapid polymerization of the ink. This means more of the ink’s components are locked into a solid polymer matrix, with fewer free, uncured molecules available to migrate. The targeted wavelengths ensure optimal activation of photoinitiators, leading to a deeper and more thorough cure.

- Surface and Through-Cure: High-intensity LED systems, when properly configured, deliver high irradiance levels. This high energy density promotes not only surface cure but also thorough through-cure, effectively solidifying the entire ink layer. This is crucial for preventing migration, as even a thin layer of uncured ink can be a source of migrating components.

- Reduced Thermal Stress: By generating less heat, LED curing minimizes thermal stress on the ink and substrate. This helps maintain the integrity of the ink layer and the substrate’s barrier properties, preventing pathways for migration. In some cases, excessive heat from traditional lamps can even plasticize the ink, making it more prone to migration.

- Consistent Curing Performance: The consistent and reliable output of LED systems ensures that each print run achieves the same level of cure. This predictability is vital for maintaining quality control and adhering to strict regulatory standards, especially in food contact applications. Variabilities in mercury lamp output can lead to inconsistent curing and, consequently, unpredictable migration levels.

- Suitability for Sensitive Applications: The ability of LED curing to operate at lower temperatures makes it ideal for printing on sensitive materials such as thin films, certain plastics, and recycled content, which are often used in packaging and are more prone to migration issues due to their inherent properties or processing requirements.

Implementing LED Curing in Flexographic and Offset Narrow Web Printing

The integration of high-intensity LED curing technology into narrow web printing, encompassing both flexographic and offset processes, is straightforward and offers immediate benefits:

For Flexographic Printing:

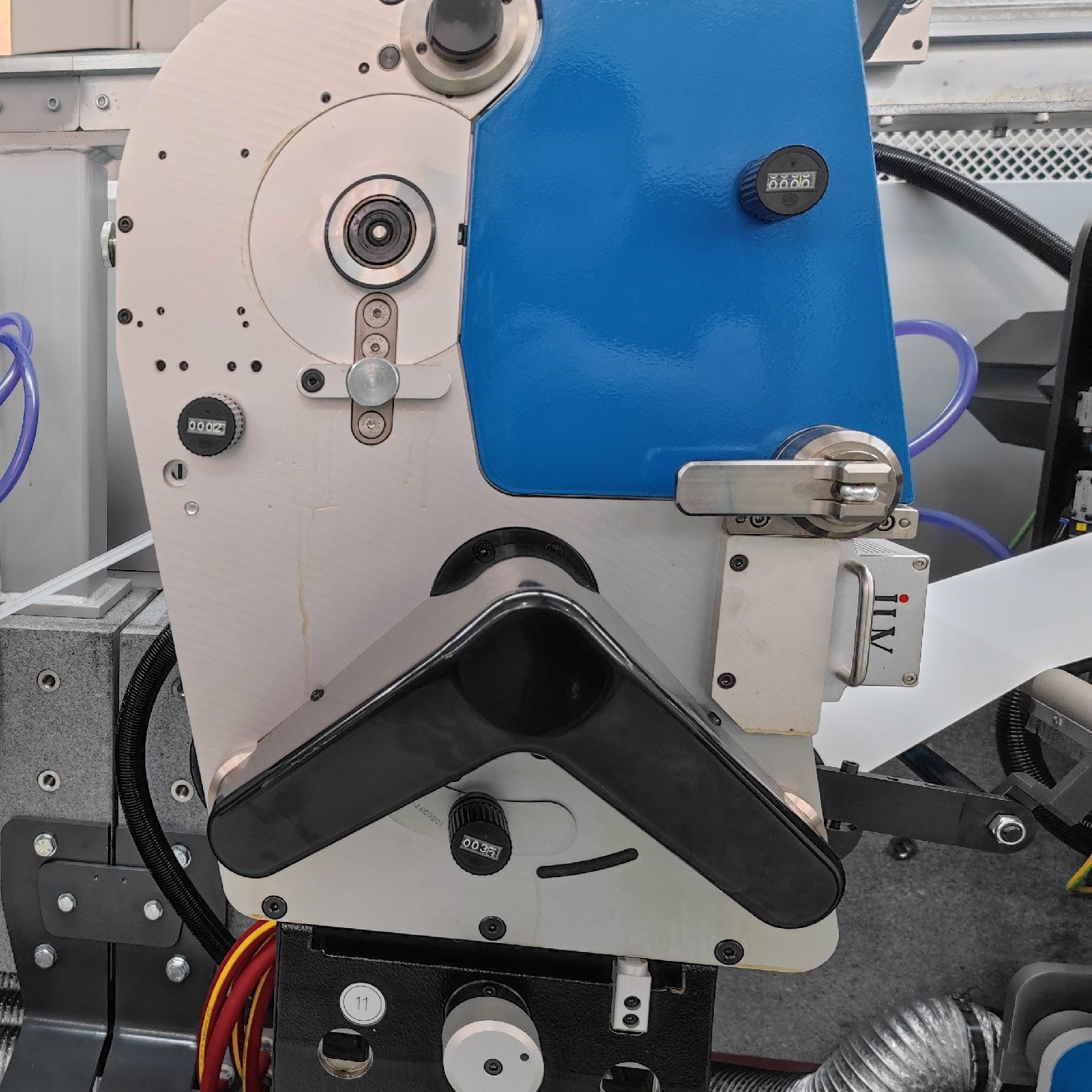

Flexography is a popular choice for narrow web labels and flexible packaging. Integrating LED curing systems involves replacing traditional mercury lamps with LED arrays at each print station or in a final curing unit.

- Process Considerations: Printers need to ensure their UV-curable inks are formulated with photoinitiators that respond efficiently to the specific wavelengths of the chosen LED system (e.g., 395 nm is common). Many ink manufacturers now offer LED-specific ink series.

- Benefits: Enhanced print quality, faster press speeds due to efficient curing, reduced downtime, and crucially, a significant reduction in the risk of ink migration for food and pharmaceutical labels. The ability to print on a wider range of substrates, including sensitive films, expands application possibilities.

For Offset Printing:

Narrow web offset printing is utilized for high-quality labels, flexible packaging, and specialty printing. Similar to flexography, LED curing systems replace existing UV lamp units.

- Process Considerations: Offset inks, especially those used for UV curing, need to be compatible with LED wavelengths. The high irradiance of LED systems can lead to very fast curing, requiring printers to manage ink tack and transfer effectively.

- Benefits: Achieving excellent dot definition and print fidelity is maintained, while the benefits of LED curing—reduced heat, energy savings, and improved migration control—are realized. This is particularly valuable for high-value, short-run label production where quality and safety are paramount.

Choosing the Right LED System

Selecting the appropriate high-intensity LED curing system involves several considerations:

- Wavelength: The primary wavelength output (e.g., 365nm, 395nm) must match the photoinitiators in your chosen inks.

- Irradiance: This is the intensity of the UV light output, measured in W/cm². Higher irradiance leads to faster and more thorough curing. The required irradiance depends on ink type, ink film thickness, substrate, and press speed.

- Dose: The total energy delivered, calculated as irradiance multiplied by exposure time. This is critical for complete cure.

- Cooling: While LEDs run cooler than mercury lamps, high-intensity systems still require effective cooling, usually air or water, to maintain optimal performance and longevity.

- Integration: The physical dimensions and power requirements of the LED system must be compatible with your existing printing press.

Consulting with ink suppliers and LED curing equipment manufacturers is essential to ensure optimal system selection and configuration for your specific application and press setup.

Conclusion

The imperative to reduce ink migration is non-negotiable in today’s print landscape, driven by regulatory demands and consumer safety concerns. High-intensity LED curing technology offers a robust, efficient, and reliable solution for narrow web flexographic and offset printers. By providing precise wavelength targeting, exceptional irradiance, and lower operating temperatures, LED systems ensure a more complete ink cure, dramatically minimizing the risk of ink migration. Embracing this advanced curing technology not only enhances product safety and brand trust but also unlocks significant operational efficiencies and cost savings, positioning printers for continued success in a competitive market.