In the competitive landscape of modern printing, efficiency is paramount. For businesses focused on label printing, flexography, offset lithography, and narrow web applications, optimizing energy consumption directly impacts profitability and environmental responsibility. A significant area for improvement lies within the UV curing process, specifically through the performance optimization of UV inks. Leveraging advanced LED UV curing technology offers a powerful pathway to substantial energy savings.

The transition from traditional mercury vapor lamps to LED UV systems represents a fundamental shift in curing technology. Mercury lamps are notorious for their high energy draw and the considerable heat they generate, much of which is wasted energy. LED UV systems, conversely, are highly targeted, emitting light only at specific wavelengths that efficiently cure UV inks. This precision translation of electrical energy into curing energy is the cornerstone of their efficiency.

The Science of Efficient UV Ink Curing

UV inks cure through a photochemical process. When exposed to UV light of the correct wavelength and intensity, photoinitiators within the ink absorb this energy. This absorption triggers a chain reaction, rapidly polymerizing the ink’s components into a solid, durable film. The efficiency of this process hinges on several factors: the ink formulation itself, the spectrum of the UV light source, and the intensity of that light.

Optimizing UV ink performance means ensuring that the ink formulation is perfectly matched to the characteristics of the LED UV system. This involves considering the absorption spectrum of the photoinitiators and selecting inks designed to be cured by the specific wavelengths emitted by the chosen LED lamps. Not all UV inks are created equal, and their responsiveness to different UV spectra varies significantly.

LED UV: A Game Changer for Energy Reduction

LED UV curing technology offers inherent energy advantages. Unlike mercury lamps, which require a warm-up period and constantly consume power, LEDs can be switched on and off instantaneously. This means energy is only used when actively curing. Furthermore, LEDs operate at much lower temperatures than mercury lamps, significantly reducing the need for extensive and energy-intensive cooling systems. The heat generated by LEDs is largely directed into the curing process, rather than being dissipated into the surrounding environment.

Consider the power requirements. A typical mercury lamp system might consume several kilowatts of power, a large portion of which is lost as heat. A comparable LED UV system can achieve excellent cure levels using a fraction of that power. This reduction in energy consumption translates directly into lower electricity bills, a tangible benefit for any printing operation.

Optimizing Ink Performance for Narrow Web and Label Printing

For narrow web and label printers, the speed and quality of production are critical. Integrating LED UV curing requires a nuanced approach to ink selection and press setup. Modern ink manufacturers have developed specialized UV inks formulated to perform exceptionally well under LED UV light. These inks often feature advanced photoinitiator packages and resin systems that respond efficiently to the narrow bandwidths characteristic of LED emitters.

When selecting inks, it’s important to work with suppliers who understand LED UV technology. They can provide inks that:

- Match LED Wavelengths: Ensuring the photoinitiators absorb light effectively at the 365nm, 385nm, 395nm, or 405nm wavelengths commonly used in LED systems.

- Achieve Fast Cure Speeds: Allowing for higher press speeds without compromising print quality or ink adhesion.

- Minimize Energy Input: Requiring less UV energy (measured in Joules/cm²) to reach a full cure.

- Reduce Heat Generation: Minimizing heat transfer to the substrate, which is particularly important for heat-sensitive label materials.

Flexographic Printing and LED UV Optimization

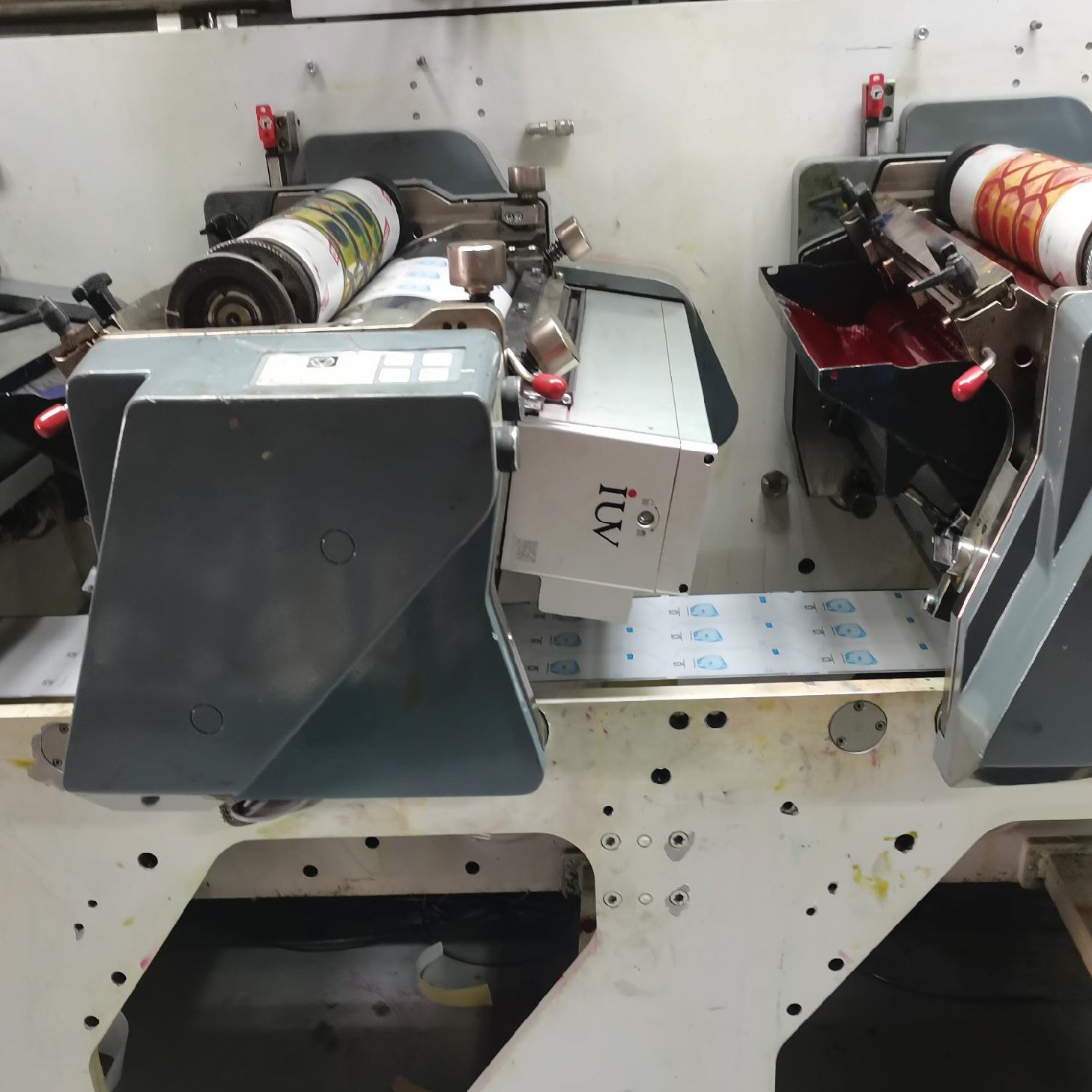

In flexographic printing, especially for packaging and labels, the ability to cure ink rapidly and efficiently is crucial. LED UV systems integrate seamlessly into flexo presses, offering distinct advantages. The precise control over UV output allows for consistent curing across long print runs. This consistency is vital for maintaining brand color fidelity and ensuring the structural integrity of the printed product.

Optimizing LED UV performance in flexo involves not just ink selection but also understanding the interaction between the UV lamps, anilox rolls, printing plates, and the substrate. The distance between the LED head and the ink film, the speed of the press, and the anilox cell volume all play a role in achieving optimal ink transfer and subsequent curing. By fine-tuning these parameters, printers can maximize the efficiency of the UV energy delivered to the ink.

Offset Lithography and the LED UV Advantage

While offset lithography is often associated with larger formats, narrow web offset presses are increasingly popular for label and specialty printing. Here too, LED UV curing offers significant benefits. Traditional offset UV inks can be energy-intensive to cure. LED UV inks formulated for offset can achieve full cure with lower energy input and less heat. This is particularly advantageous when printing on plastic films or thin paper stocks that can be sensitive to heat.

The ability of LED UV to deliver targeted energy means that printers can achieve excellent gloss, scuff resistance, and color vibrancy without the risk of substrate deformation or discoloration often associated with older UV technologies. The immediate curing also allows for faster handling and finishing processes, streamlining the entire production workflow.

Practical Steps for Performance Optimization

- Audit Existing Systems: Assess the energy consumption and efficiency of your current UV curing setup.

- Consult with Ink and Equipment Suppliers: Engage with experts in UV ink formulations and LED UV curing systems. Seek out partners who can provide solutions tailored to your specific press and application.

- Specify LED UV-Compatible Inks: Prioritize inks designed for LED UV curing, paying close attention to their photoinitiator packages and spectral response.

- Calibrate LED Systems: Ensure your LED UV lamps are properly calibrated for wavelength, intensity, and uniformity across the web width. Regular maintenance is key.

- Monitor Curing Parameters: Track critical curing parameters such as UV dose (mJ/cm²) and peak irradiance (W/cm²) to ensure consistent results.

- Test and Validate: Conduct thorough testing to confirm cure levels and adhesion on your specific substrates.

By strategically optimizing the performance of UV inks in conjunction with advanced LED UV curing technology, printing businesses can achieve significant reductions in energy consumption. This not only leads to substantial cost savings but also contributes to a more sustainable printing operation. Embracing these advancements is no longer just an option; it’s a strategic imperative for staying competitive and environmentally conscious in today’s demanding print market.