Automated printing processes are constantly evolving, demanding precision and consistency. In this landscape, achieving predictable results is paramount. One of the most impactful technologies driving this predictability is LED UV curing. However, simply deploying UV lamps isn’t enough. The real game-changer lies in Real-Time UV Energy Management for Predictable Results in Automated Printing. This article dives into why mastering UV energy in real-time is no longer optional, but a core requirement for modern printing operations, especially within label, flexographic, and offset printing sectors.

The Foundation: Understanding UV Curing in Print

UV curing utilizes ultraviolet light to instantly polymerize inks, coatings, and adhesives. This process offers significant advantages over traditional drying methods, including faster speeds, improved durability, enhanced gloss, and reduced VOC emissions. For narrow-web label printers, flexographic operations, and offset presses, UV curing has become a standard for high-quality output. The transition from mercury vapor lamps to energy-efficient LED UV systems has further revolutionized the field, offering more controlled light output and longer operational life.

Why Real-Time Energy Management Matters

Think of UV curing as a chemical reaction triggered by light. For this reaction to be complete and consistent, the precise amount of energy must be delivered to the substrate. Fluctuations in UV energy can lead to a cascade of problems:

- Incomplete Curing: This is perhaps the most critical issue. If the ink or coating doesn’t receive enough UV energy, it remains under-cured. This can result in poor adhesion, scratch resistance, and chemical resistance. In the label printing world, this means labels that peel off, scratch easily, or lose their print quality when exposed to product contents or handling.

- Over-Curing: While less common, excessive UV energy can sometimes lead to substrate degradation, yellowing of inks, or brittle coatings. This is particularly concerning for sensitive substrates used in specialized label applications or delicate paper stocks in offset printing.

- Inconsistent Color and Gloss: The appearance of printed materials heavily relies on uniform curing. Variations in UV energy across the web can cause patchiness in color saturation and inconsistent gloss levels, directly impacting brand aesthetics and customer satisfaction. For flexographic and offset printing, where vibrant colors and a smooth finish are often selling points, this is a significant drawback.

- Increased Waste and Downtime: When prints fail quality checks due to curing issues, entire jobs can be rejected. This leads to material waste, lost production time, and the cost of reprinting. For narrow-web printers operating on tight margins, this is a substantial financial hit.

The Role of LED UV Technology

LED UV systems have significantly improved the controllability of UV energy. Unlike mercury lamps, which emit a broad spectrum of light and require warm-up/cool-down periods, LEDs offer instant on/off capabilities and a more focused wavelength output. This precision is foundational for real-time energy management. However, the LED system itself needs to be monitored and adjusted dynamically.

Components of a Real-Time UV Energy Management System

A robust system for managing UV energy in real-time typically involves several key components working in concert:

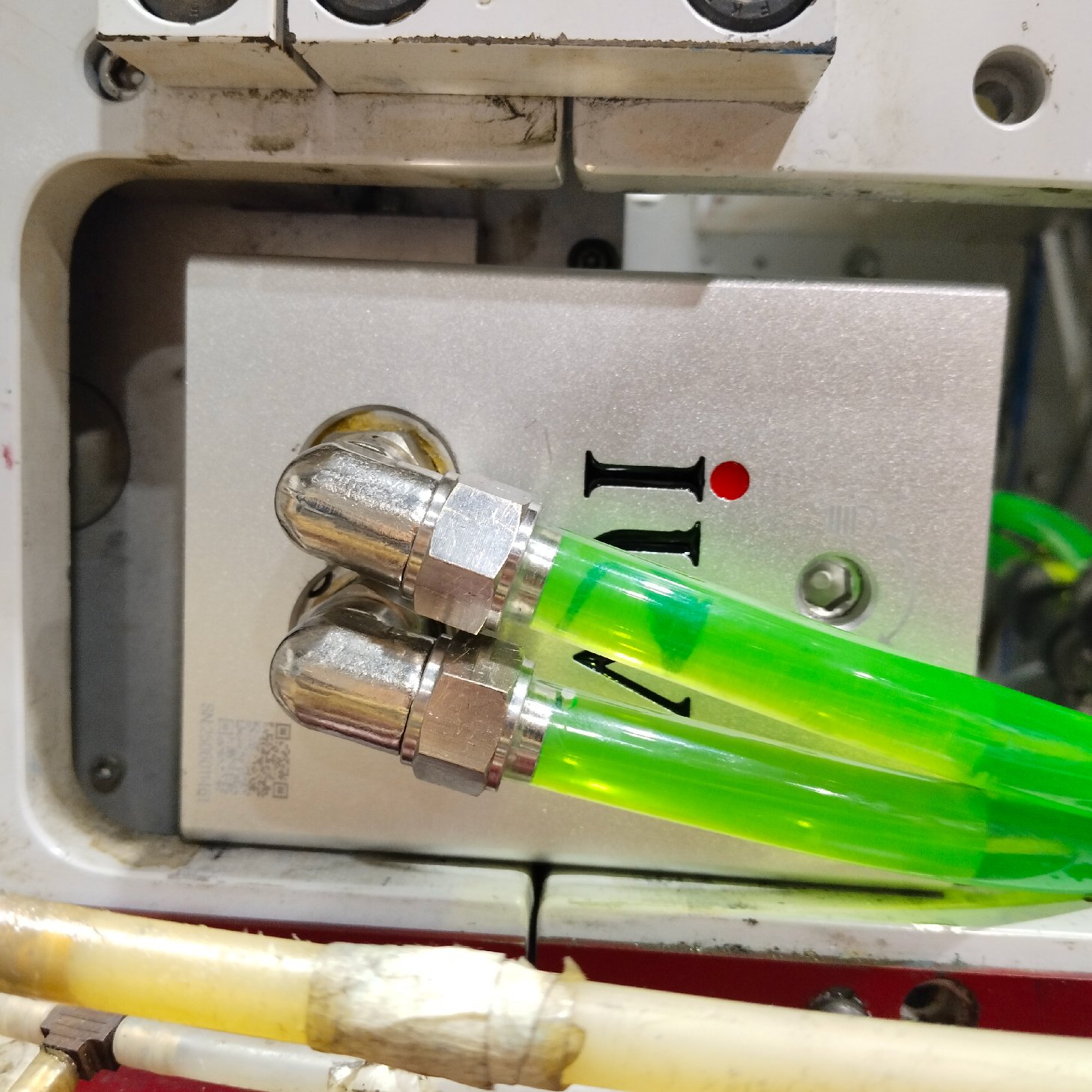

- UV-A Radiometers/Sensors: These devices are crucial for measuring the actual UV irradiance (power density) and dose (total energy per area) delivered to the substrate. They are strategically placed within the printing press, often after each UV curing unit.

- Process Control Software: This is the brain of the operation. The software receives data from the radiometers and compares it against pre-set target values. It then communicates with the UV lamp controllers.

- UV Lamp Controllers: These integrated systems allow for precise adjustment of the power output of the LED UV lamps. They can ramp up or down the intensity of the lamps based on instructions from the process control software.

- Integration with Press Controls: For truly seamless operation, the UV energy management system should be integrated with the main printing press control system. This allows for automated adjustments based on press speed, substrate type, and ink formulation changes.

Achieving Predictable Results Across Print Processes

The principles of real-time UV energy management are universally applicable, but their implementation and benefits are particularly pronounced in specific printing applications:

Narrow-Web Label Printing

In the competitive label market, speed and consistency are everything. Narrow-web presses often run at high speeds, and even minor variations in UV curing can lead to significant quality defects.

- UV Energy and Adhesion: For labels requiring durable adhesion, particularly those exposed to demanding environments (e.g., automotive, industrial, or cosmetic packaging), precise UV energy ensures the adhesive fully cures, preventing delamination. Real-time monitoring guarantees consistent adhesion across the entire roll.

- Color Accuracy and Brand Integrity: Brands demand exact color reproduction. Inconsistent UV energy can cause color shifts. A real-time management system ensures that the color remains true from the first label printed to the last, vital for brand recognition and compliance.

- Specialty Finishes: Applications involving tactile varnishes, foiling, or pearlescent effects rely heavily on precise UV curing to achieve their desired aesthetic and functional properties. Real-time energy management ensures these finishes are applied and cured uniformly, without compromising the underlying ink or substrate.

Flexographic Printing

Flexography, especially in packaging, is a high-volume, high-speed process where any disruption can be costly.

- Ink and Coating Durability: Flexo inks and coatings are often designed for robust performance in harsh conditions. Insufficient UV energy leads to premature wear, scratching, or chemical bleed. Real-time control ensures these protective layers are fully cured and effective throughout the product’s lifecycle.

- Managing Different Wavelengths: Modern flexo presses may use UV or UV-LED systems with different wavelength outputs for various inks. Real-time management allows for precise control over the specific wavelengths needed for optimal curing of each ink type, ensuring consistent performance even when switching between different ink sets.

- Substrate Versatility: Flexo printers handle a vast array of substrates, from films and foils to paper. Each material absorbs and transmits UV light differently. Real-time energy adjustments compensate for these variations, ensuring predictable curing regardless of the substrate, maintaining quality across diverse packaging needs.

Offset Printing

While offset printing has traditionally relied on heatset or conventional drying, UV curing is increasingly adopted for its speed and finish.

- High-Gloss and Matte Finishes: Achieving a consistent gloss or matte effect with UV coatings requires uniform energy application. Real-time management prevents hot spots or under-cured areas, leading to a flawless, consistent finish across large print runs.

- Paper Stock Variations: Different paper stocks can have varying porosity and surface characteristics, affecting ink absorption and UV light penetration. Real-time UV energy control helps compensate for these differences, ensuring predictable ink and coating performance even on challenging paper types.

- Book Covers and Commercial Print: For high-end commercial printing, like book covers or brochures, visual appeal is paramount. Precise UV curing ensures vibrant colors, sharp details, and durable finishes that withstand handling, contributing to a premium product perception.

Implementing Real-Time UV Energy Management

Adopting real-time UV energy management involves a strategic approach:

- Assess Your Current System: Understand the capabilities of your existing UV curing units. Are they LED or mercury-based? Can their power output be controlled digitally?

- Invest in Measurement Tools: Procure reliable, calibrated UV radiometers. Regular calibration is key to maintaining accuracy.

- Select Appropriate Software: Choose process control software that integrates seamlessly with your UV equipment and press controls. Look for user-friendly interfaces that provide clear data visualization.

- Develop Standard Operating Procedures (SOPs): Establish clear protocols for setting target UV energy levels for different jobs, substrates, and inks. Train your operators on how to monitor the system and respond to alerts.

- Continuous Monitoring and Calibration: Regularly monitor system performance, review historical data, and ensure all measurement equipment remains calibrated.

The Future of Printing: Intelligent UV Curing

As automation continues to permeate the printing industry, intelligent UV curing systems will become standard. These systems will not only manage energy in real-time but will also learn and adapt. Machine learning algorithms could predict optimal UV settings based on job parameters, ink chemistry, and even environmental conditions. This level of foresight moves beyond merely reacting to issues to proactively ensuring perfect results every time.

For any automated printing operation striving for peak performance, consistency, and minimal waste, implementing real-time UV energy management is a critical investment. It empowers printers to deliver predictable, high-quality results, job after job, solidifying their competitive edge in today’s demanding market.