The demand for visually stunning and highly tactile labels is constantly growing, especially within the premium beverage and cosmetic sectors. These labels are not just identifiers; they are crucial brand ambassadors, conveying quality, luxury, and exclusivity. Achieving this level of presentation on narrow-web presses, particularly for flexible packaging and self-adhesive labels, presents a unique set of challenges and opportunities. This is where narrow-web LED flexo technology emerges as a game-changer, offering unparalleled advantages in performance, efficiency, and sustainability.

The Evolution of Narrow-Web Printing

Narrow-web printing, typically defined as printing on substrates less than 13 inches wide, has long been the backbone of label production. Historically, flexographic (flexo) printing has dominated this space due to its versatility, cost-effectiveness, and suitability for a wide range of substrates, from paper and film to foil. Flexo printing, with its raised image carriers, excels at applying inks consistently across various surfaces, making it ideal for intricate designs and vibrant color reproduction.

However, traditional UV curing methods, while effective, came with their own set of drawbacks. Conventional UV lamps, such as mercury vapor lamps, generated significant heat, which could damage heat-sensitive substrates common in cosmetic packaging. This heat also increased energy consumption and required substantial ventilation systems. Furthermore, the warm-up and cool-down times of these lamps reduced press efficiency and led to greater waste during job changes.

Introducing LED UV Curing: A Paradigm Shift

Light Emitting Diode (LED) UV curing technology represents a significant leap forward. Instead of relying on broad-spectrum mercury lamps, LED curing uses an array of semiconductor diodes that emit UV light at specific wavelengths. This targeted emission is not only more efficient but also drastically reduces the heat output onto the substrate.

For narrow-web flexo printing, this translates into several critical benefits.

Superior Substrate Compatibility

Many premium cosmetic and beverage labels are printed on delicate films, foils, or specialized papers. The minimal heat generated by LED UV systems means that these sensitive materials can be printed without distortion, bubbling, or delamination. This expands the range of possible substrates, allowing for greater creative freedom in label design and material selection. Think of the soft-touch finishes or metallic effects that can now be achieved without compromise.

Enhanced Print Quality and Definition

LED curing provides a more uniform and controllable UV output. This consistency leads to sharper dot definition, better ink adhesion, and brighter, more vibrant colors. For brands targeting a premium market, the ability to reproduce fine details, intricate patterns, and subtle color gradients is paramount. LED flexo technology ensures that every element of the design, from delicate typography to complex imagery, is rendered with exceptional clarity and fidelity. This is particularly important for brand recognition and conveying a sense of high quality.

Increased Press Speeds and Throughput

The immediate on/off capability of LED lamps means there are no lengthy warm-up or cool-down periods. Presses can reach operating speed much faster, and job changes are significantly streamlined. This translates directly into higher productivity and reduced downtime. For label converters operating in competitive markets, this boost in throughput can be a major differentiator, allowing for quicker turnaround times and greater order fulfillment capacity.

Energy Efficiency and Environmental Benefits

Compared to traditional UV lamps, LED UV systems consume significantly less energy. Their longer lifespan also reduces waste associated with lamp replacement. The lower heat output means less demand on cooling systems and ventilation. This not only contributes to a more sustainable printing operation but also lowers operational costs. In an era where environmental responsibility is increasingly important to consumers, especially in the beverage and cosmetic industries, adopting energy-efficient technologies like LED curing can enhance a brand’s green credentials.

Reduced VOC Emissions

LED UV inks are typically formulated with 100% solids, meaning they contain no volatile organic compounds (VOCs) that evaporate during the curing process. This results in cleaner air in the printing environment and a more environmentally friendly end product. For beverage and cosmetic labels, where direct food contact or skin application is a consideration, the absence of VOCs is a significant advantage, contributing to safer and cleaner labels.

Applications in Premium Labels

The synergy between narrow-web flexo printing and LED UV curing is particularly impactful for premium beverage and cosmetic labels.

Beverage Labels: For craft beers, premium wines, and artisanal spirits, labels are often the first point of contact with the consumer. LED flexo allows for the use of special effect inks, metallic foils, and tactile varnishes to create eye-catching designs that stand out on the shelf. The durability of UV-cured inks ensures that labels withstand condensation and handling.

Cosmetic Labels: The beauty industry demands packaging that exudes sophistication and luxury. LED flexo printing enables the reproduction of intricate details, gradients, and high-gloss finishes on a variety of substrates. The ability to print on plastics, films, and foils without heat damage is crucial for achieving the desired aesthetic. Furthermore, the enhanced scratch and chemical resistance of UV-cured inks protects the label’s integrity, even in demanding environments like bathrooms.

Beyond the Basics: Optimizing LED Flexo for Labels

To fully leverage narrow-web LED flexo technology, consider these aspects:

- Ink Formulation: Work with ink manufacturers specializing in LED-curable inks. These inks are specifically designed to cure efficiently under the specific wavelengths emitted by LED lamps. Different formulations exist for various substrates and desired finishes.

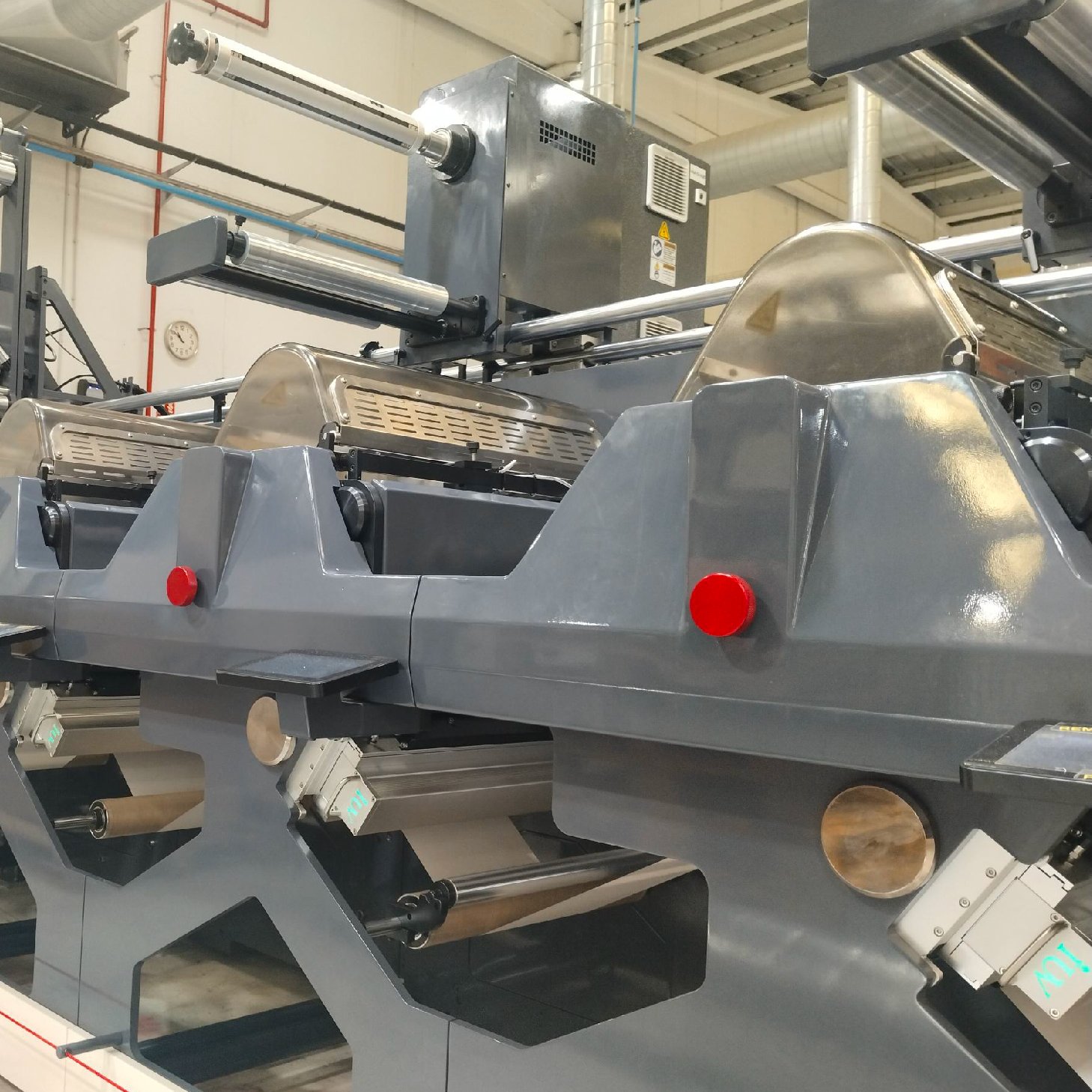

- Press Configuration: Ensure your flexo press is equipped with appropriately positioned LED UV curing units. The placement is critical to ensure optimal curing of each ink layer without affecting subsequent stations or substrate integrity. Consider hybrid press configurations that combine flexo with digital printing capabilities for maximum flexibility.

- Substrate Selection: Explore the possibilities offered by LED curing. Experiment with different films, textured papers, and metallic substrates to discover new aesthetic and tactile effects.

- Color Management: With the precise color reproduction capabilities of LED flexo, implementing robust color management systems is essential to achieve consistent brand colors across all print runs and substrates.

The Future is Bright with LED Flexo

Narrow-web LED flexo technology is not just an incremental improvement; it’s a transformative solution for the production of premium beverage and cosmetic labels. It delivers higher print quality, greater substrate flexibility, improved efficiency, and significant environmental advantages. As brands continue to seek differentiation and consumers increasingly value sustainable and high-quality products, embracing LED flexo technology is a strategic imperative for label converters aiming to lead in the market. This technology empowers printers to meet and exceed the demanding requirements of high-end label applications, ensuring that every bottle and every compact tells a story of excellence.