In the fast-paced world of label and narrow web printing, unexpected equipment downtime is more than just an inconvenience; it’s a direct hit to your bottom line. Every minute your automated UV printing line is idle, you’re losing production capacity, missing delivery deadlines, and potentially frustrating clients. This is especially true in high-volume sectors like flexible packaging and commercial label printing where efficiency is paramount. The intricate nature of modern printing presses, particularly those employing advanced LED UV curing technology, means that when something goes wrong, it can cascade into significant disruptions.

Understanding the Pillars of Automation in UV Printing

Modern automated UV printing lines are marvels of engineering. They integrate multiple complex subsystems, from material handling and precise ink delivery to sophisticated color management and, of course, the critical UV curing stations. For narrow web flexo presses, for instance, this often means a series of print stations, each followed by an LED UV lamp for immediate ink setting. Similarly, in offset or hybrid narrow web systems, controlled curing is essential for multi-layer applications or rapid turnaround jobs. The automation lies not just in the speed but in the integrated control systems that orchestrate these processes seamlessly. When one component falters, the entire line can grind to a halt.

The Role of LED UV Curing in Modern Printing

LED UV curing has revolutionized the printing industry. Unlike traditional mercury vapor lamps, LEDs offer instant on/off capabilities, lower heat emission, longer lifespan, and significantly reduced energy consumption. This makes them ideal for high-speed, high-quality printing, especially on heat-sensitive substrates common in label and flexible packaging. The precise control over UV output is a key benefit, ensuring optimal ink polymerization without over-curing or under-curing, which can lead to print defects and wasted materials. However, these advanced systems, while reliable, are not immune to issues.

The Challenge: Predictive vs. Reactive Maintenance

Historically, maintenance in printing operations has often been reactive. Machines are run until they break, and then repairs are initiated. This approach is inherently inefficient. It leads to unplanned downtime, emergency part orders (which are often more expensive), and the potential for collateral damage to other components. Predictive maintenance, on the other hand, shifts the paradigm. Instead of waiting for failure, it uses data and analysis to anticipate and address potential problems before they cause a breakdown. This is where predictive diagnostics become a game-changer for automated UV printing lines.

Introducing Predictive Diagnostics for UV Printing Lines

Predictive diagnostics leverage sensors, data collection, and sophisticated algorithms to monitor the health of critical machine components in real-time. For an automated UV printing line, this means equipping various parts of the system with sensors that can measure parameters like temperature, vibration, current draw, motor performance, and UV lamp output.

- Temperature Monitoring: Overheating in motors, bearings, or even within the UV curing units can signal impending failure. Predictive diagnostics can alert operators to rising temperatures long before they reach a critical level, allowing for investigation and preventative action, such as cleaning cooling fans or lubricating bearings.

- Vibration Analysis: Unusual vibration patterns in rollers, gears, or drive systems are often precursors to mechanical wear and tear. By analyzing vibration frequencies and amplitudes, engineers can identify specific components that are degrading and schedule their replacement during planned maintenance windows.

- Electrical Load Monitoring: Changes in the electrical current drawn by motors or UV lamps can indicate increased strain or an internal fault. For LED UV systems, monitoring the power supply and individual diode performance can flag issues that might lead to inconsistent curing or premature lamp failure.

- Performance Metrics: Tracking key operational metrics like speed consistency, ink viscosity stability, and registration accuracy provides a baseline for normal performance. Deviations from this baseline can point to underlying issues, such as a failing drive motor, a worn ink pump, or a calibration drift in the control system.

Focusing on Key Components in Automated UV Printing

When implementing predictive diagnostics on an automated UV printing line, certain areas warrant particular attention:

- Drive Motors and Gearboxes: These are the workhorses. Sensors can monitor their temperature, vibration, and load. Early detection of bearing wear or gear tooth damage can prevent catastrophic failure and ensure consistent web speed and tension control, vital for precise ink laydown and registration.

- Web Handling and Tension Control Systems: Maintaining consistent web tension is critical in flexo and offset printing. Issues with dancer rollers, load cells, or motor controllers can lead to web breaks or poor print quality. Predictive diagnostics can monitor the responsiveness and stability of these systems.

- Ink Delivery Systems: Pumps, valves, and viscosity controllers must operate flawlessly. Monitoring motor current, flow rates, and temperature can identify potential blockages, pump wear, or controller malfunctions before they cause ink starvation or over-application.

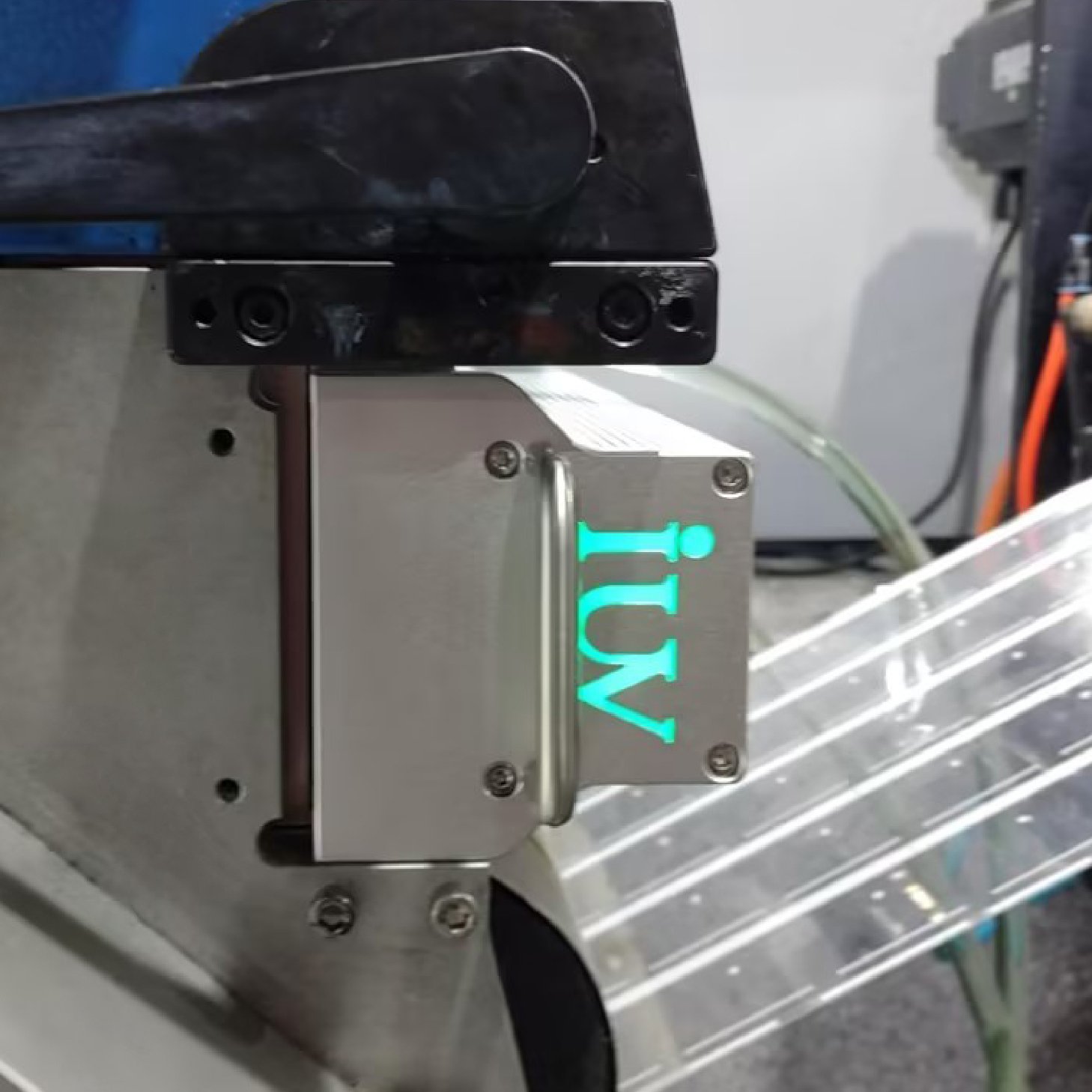

- LED UV Curing Systems: This is a crucial area. While LEDs are robust, they do have a lifespan. Monitoring individual LED module temperatures, current draw, and the overall power output of the curing units provides invaluable data. Early detection of a failing module or power supply issue can prevent under-cured ink, leading to smudging, poor adhesion, or failed rub tests. For hybrid presses that might use both UV and conventional inks, understanding the curing performance of each station is paramount.

- Automated Inspection and Quality Control Systems: While not directly part of the printing mechanism, these systems rely on stable operation. If a camera or sensor is affected by excessive vibration or an unstable power supply, its ability to detect defects is compromised, leading to flawed products passing through or unnecessary line stoppages.

Implementing a Predictive Diagnostics Strategy

Adopting a predictive diagnostics approach requires a structured plan:

- Identify Critical Assets: Map out your automated UV printing line and identify the components most likely to cause significant downtime.

- Select Appropriate Sensors: Choose sensors that can accurately measure the relevant parameters for each critical asset. Compatibility with your existing control systems (e.g., PLC, SCADA) is key.

- Data Collection and Storage: Establish a robust system for collecting, storing, and managing the sensor data. This might involve dedicated data acquisition hardware or leveraging existing network infrastructure.

- Analysis and Alerting: Implement analytical tools or software that can process the data, identify patterns indicative of potential failure, and generate alerts. This can range from simple threshold alarms to advanced machine learning algorithms.

- Maintenance Planning Integration: Ensure that the alerts generated by the predictive diagnostic system are fed directly into your Computerized Maintenance Management System (CMMS) or your maintenance planning process. This allows for scheduled repairs during planned downtimes.

- Continuous Improvement: Regularly review the effectiveness of your predictive diagnostics program. Refine sensor placement, adjust alert thresholds, and update analytical models as you gain more operational experience.

The Payoff: Reduced Downtime, Increased Profitability

The investment in a predictive diagnostics system for your automated UV printing lines pays significant dividends. By shifting from reactive to proactive maintenance, you can:

- Drastically Reduce Unplanned Downtime: Addressing issues before they cause a shutdown means fewer emergency stops and smoother production runs.

- Optimize Maintenance Scheduling: Repairs and part replacements can be planned for periods of low production, minimizing impact.

- Extend Equipment Lifespan: Proactive maintenance prevents minor issues from escalating into major damage, extending the operational life of your valuable printing assets.

- Improve Print Quality and Reduce Waste: Consistent machine performance leads to more stable print processes, fewer defects, and less material waste.

- Enhance Operator Safety: Preventing unexpected equipment failures can reduce the risk of accidents on the shop floor.

- Increase Overall Equipment Effectiveness (OEE): By minimizing downtime and improving performance, you directly boost your OEE, a key metric for manufacturing efficiency.

For businesses in narrow web label printing, flexible packaging, and any sector relying on high-speed UV printing, embracing predictive diagnostics isn’t just an option; it’s a strategic imperative for maintaining a competitive edge and ensuring long-term profitability. It transforms maintenance from a cost center into a value driver.