Okay, consider it done! I’ll put on my dual hats as a print engineer and SEO wordsmith to craft a compelling piece on maximizing productivity with LED curing systems. Here we go:

The commercial printing landscape is constantly evolving. Businesses demand faster turnarounds and higher quality. Achieving these goals often hinges on optimizing every stage of the production process. One area ripe for improvement is print curing. Traditional curing methods can be slow and energy-intensive. This is where modern LED UV curing technology steps in. It offers a significant boost in productivity for various printing applications.

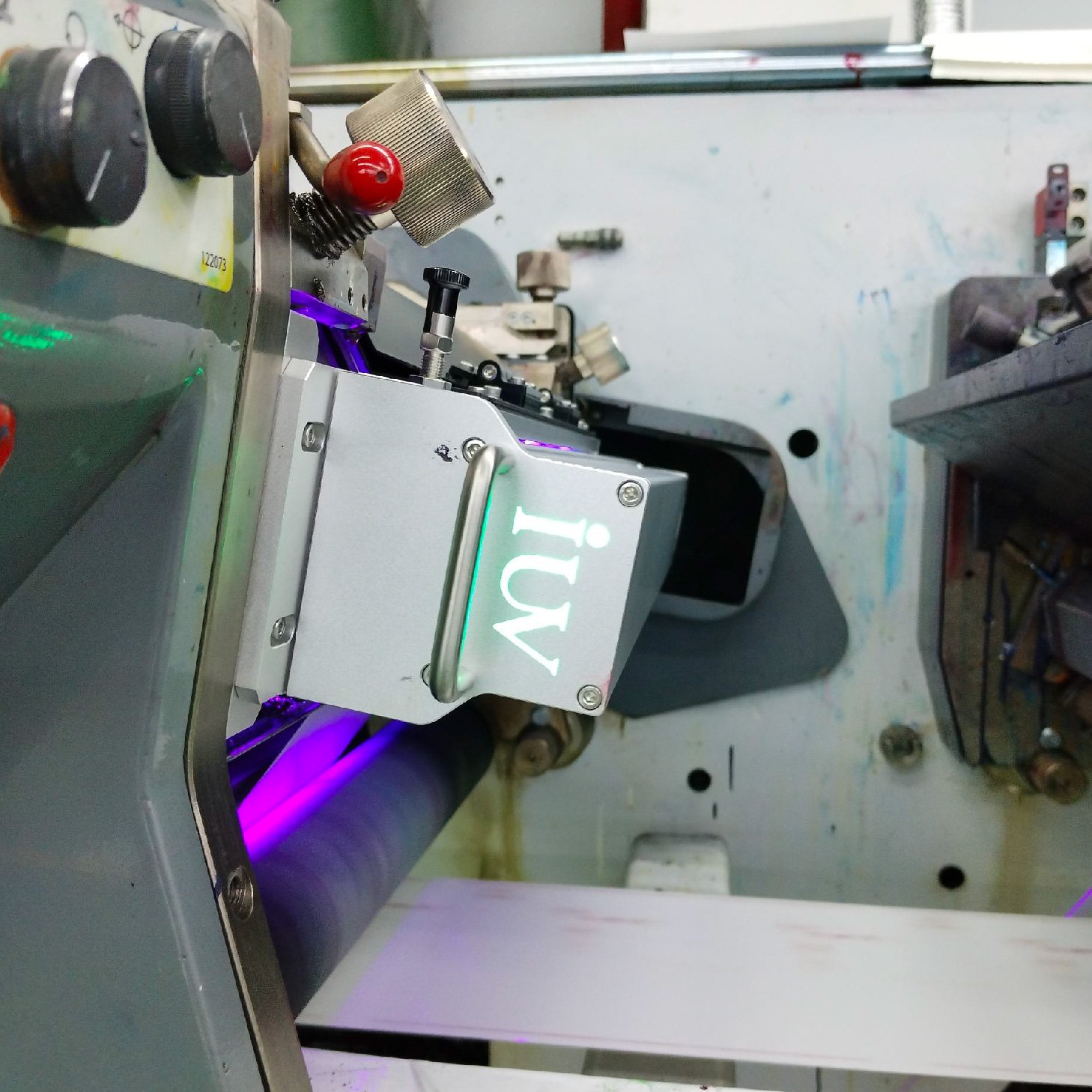

LED UV curing uses light-emitting diodes to generate UV light. This light instantly dries (or cures) inks and coatings. This process is remarkably efficient. It’s a game-changer, especially in demanding sectors like label printing.

LED Curing in Label Printing: A Perfect Fit

Label printing, whether for consumer goods or industrial applications, often involves short runs and tight deadlines. The ability to switch between jobs quickly is paramount. LED UV curing excels here. It allows for immediate handling of printed materials. There’s no waiting for inks to dry. This means less paper waste and fewer errors. Presses can run at higher speeds without compromising ink adhesion. This directly translates to increased output. For narrow web printers, this speed advantage is even more pronounced. Narrow web presses are designed for efficiency. Integrating LED UV curing maximizes their inherent capabilities.

Flexographic Printing and LED UV: A Powerful Alliance

Flexographic printing, or flexo, is a versatile printing method. It’s widely used for packaging, labels, and flexible materials. Traditionally, flexo presses relied on heat or mercury vapor lamps for curing. These systems have drawbacks. They consume significant energy. They also generate considerable heat, which can affect delicate substrates. Mercury lamps also pose disposal concerns.

LED UV curing offers a compelling alternative for flexo. It cures inks and coatings much faster. This enables higher press speeds. The low heat output of LEDs is also beneficial. It prevents substrate distortion. This is especially important when printing on thin films. Furthermore, LED lamps have a much longer lifespan than mercury lamps. They also consume less electricity. This leads to substantial operational cost savings. The environmental benefits are also noteworthy. Reduced energy consumption and the absence of mercury are significant advantages.

Offset Printing Embraces LED Efficiency

Sheetfed offset printing is another area benefiting from LED UV technology. While offset is known for its high print quality, traditional drying methods can slow down production. Heatset web offset, for instance, uses ovens that require significant warm-up and cool-down times.

LED UV curing integrated into offset presses eliminates these delays. Curing happens instantly as the sheet exits the printing unit. This allows for immediate stacking and finishing. Finishing processes like cutting, folding, or die-cutting can begin sooner. This accelerates the entire production workflow. For commercial printers handling diverse print jobs, this speed and flexibility are invaluable. The energy efficiency of LEDs also contributes to lower overheads.

The Science Behind the Speed: UV Curable Inks and Coatings

The effectiveness of LED UV curing relies on specialized UV curable inks and coatings. These formulations contain photoinitiators. When exposed to UV light of the correct wavelength, these photoinitiators trigger a rapid chemical reaction. This reaction causes the ink or coating to polymerize and solidify almost instantaneously.

LEDs emit UV light in specific wavelength ranges. It is crucial to match the ink or coating formulation to the LED lamp’s output. Common LED wavelengths for printing include 365 nm, 385 nm, 395 nm, and 405 nm. Using the correct ink/coating and LED wavelength ensures efficient and complete curing. This prevents issues like smudging or poor adhesion.

Benefits Beyond Speed: A Holistic View

The productivity gains from LED UV curing extend beyond just faster press speeds. Consider these additional advantages:

- Reduced Waste: Instant curing means fewer misprints due to drying issues. Less time spent waiting also reduces the chance of operational errors.

- Enhanced Print Quality: Precise curing control can lead to sharper dot definition and better ink laydown. This is particularly noticeable in fine details and gradients.

- Substrate Versatility: The low heat output allows printing on a wider range of heat-sensitive materials. This includes plastics, foils, and thin papers.

- Environmental Footprint: Lower energy consumption and the elimination of mercury vapor lamps contribute to a greener printing process.

- Lower Maintenance: LED lamps have a significantly longer operational life. They also require less maintenance compared to traditional lamps.

Implementing LED Curing: Key Considerations

When considering the adoption of LED UV curing systems, several factors are important.

- Press Compatibility: Ensure the LED curing system can be effectively integrated with your existing printing presses. This may involve retrofitting or selecting new equipment.

- Ink and Coating Selection: Work with ink suppliers to choose formulations optimized for your specific LED curing wavelengths and printing process.

- Ventilation: While LEDs produce less heat, proper ventilation is still necessary for a safe and healthy working environment.

- Operator Training: Ensure your press operators are trained on the new technology and its specific requirements.

The Future of Commercial Printing is Bright and Efficient

LED UV curing technology is no longer a niche solution. It’s becoming a standard for printers looking to maximize productivity and efficiency. From narrow web label printing to wider format commercial applications, the benefits are clear. Faster speeds, reduced waste, improved quality, and a lower environmental impact all contribute to a more competitive printing operation. Embracing this technology is a strategic move for any commercial printer aiming to thrive in today’s demanding market. The investment in LED curing systems pays dividends through increased throughput and operational savings.