The label printing industry is constantly seeking advancements. Brands demand vibrant colors and durable finishes. Printers need efficient processes that deliver high quality. LED UV curing technology has emerged as a significant player in achieving these goals. This article explores how LED UV systems enhance color fidelity and accelerate ink drying speeds in various label printing applications.

Understanding UV Curing Technology

Before delving into LED specifics, it’s helpful to understand traditional UV curing. This process uses ultraviolet light to instantly cure or dry inks, coatings, and adhesives. The UV light triggers a photochemical reaction within the ink formulation. This reaction causes monomers and oligomers to link together, forming a solid, durable film.

Traditional UV lamps, often mercury-based, emit a broad spectrum of UV light. While effective, they come with drawbacks. These include high energy consumption, heat generation, and a shorter lifespan. The broad spectrum can also sometimes affect sensitive substrates or cause unwanted color shifts.

The Rise of LED UV Curing

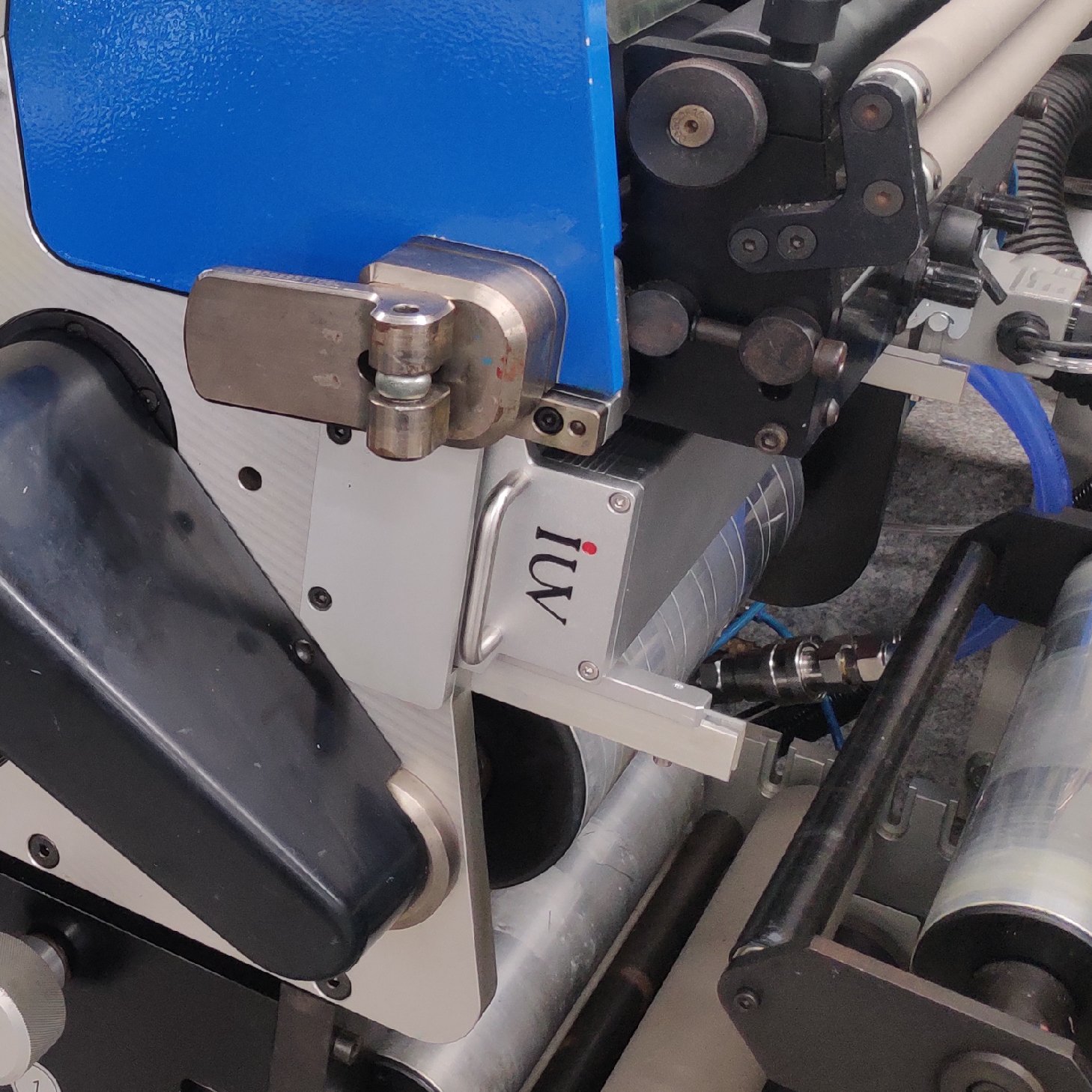

LED UV curing utilizes Light Emitting Diodes (LEDs) as the UV light source. LEDs offer a more targeted and efficient approach. They emit UV light within a specific wavelength range. This precise emission is crucial for optimal ink curing.

The advantages of LED UV are numerous. They consume significantly less energy compared to traditional lamps. LEDs also generate very little heat, which is beneficial for heat-sensitive label materials and substrates. Their lifespan is considerably longer, reducing maintenance and replacement costs. Furthermore, the instant on/off capability of LEDs means no warm-up time is needed, increasing productivity.

Enhancing Color Fidelity in Label Printing

Color fidelity is paramount in label production. A brand’s identity is often tied to its specific color palette. Any deviation can impact brand recognition and consumer perception. LED UV curing plays a vital role in maintaining and even improving color accuracy.

One key factor is the reduced heat output of LED systems. Traditional UV lamps can generate significant heat, which can cause some inks to darken or alter their appearance during the drying process. This heat-induced color shift is minimized with LED UV curing. The cool-cure nature of LEDs allows inks to retain their intended color.

Moreover, the specific wavelengths emitted by LEDs can be precisely matched to the photoinitiators in UV ink formulations. This optimized energy transfer ensures efficient and complete curing without excessive exposure. When inks cure optimally, their pigment dispersion remains stable, leading to more consistent and vibrant color reproduction across the entire print run.

Accelerating Ink Drying Speed

In the fast-paced world of label printing, drying speed is directly linked to throughput and profitability. Slow drying times create bottlenecks, reduce press speeds, and can lead to smudging or offsetting. LED UV curing offers a dramatic improvement in drying speeds.

The high intensity of UV light emitted by LEDs, within their specific wavelengths, triggers rapid polymerization of the ink. This means the ink cures almost instantaneously as it passes under the LED lamp. This rapid curing allows for immediate handling of printed labels, eliminating the need for extensive drying lines or waiting periods.

This speed is particularly valuable in high-volume narrow web label printing. Presses can run at their maximum mechanical speeds without compromising ink adhesion or finish. This translates to higher productivity and the ability to meet tight deadlines.

LED UV in Different Printing Methods for Labels

The benefits of LED UV curing extend across various printing technologies commonly used for labels.

Flexographic Printing (Flexo)

Flexographic printing is a workhorse for label production. Incorporating LED UV curing into flexo presses significantly enhances its capabilities. The fast cure allows for faster press speeds and the ability to print on a wider range of substrates, including thin films and plastics that might deform under heat. Reduced drying time means less ink migration and better print definition, especially for fine text and line work. The consistent energy output from LEDs also contributes to repeatable print quality.

Offset Printing (Sheet-fed and Web)

While often associated with larger formats, offset printing is also used for certain types of labels. In offset label printing, LED UV curing enables faster turnaround times. It allows for immediate stacking of printed sheets or the rewinding of labels from a web press. The precise curing also ensures excellent ink adhesion, which is crucial for labels that might undergo significant wear and tear or exposure to various environmental conditions.

Narrow Web Printing

Narrow web presses are specifically designed for label and flexible packaging production. They operate at high speeds and often handle intricate designs and tight registration requirements. LED UV curing is a natural fit for these presses. The instant cure enables higher speeds without offsetting or smudging. This is critical for multi-color jobs where successive colors are printed wet-on-wet. LED UV allows each layer to cure instantly, preserving the integrity of the image and color separation.

Substrate Compatibility and Environmental Advantages

LED UV curing broadens the range of compatible substrates. Because LEDs produce minimal heat, printers can confidently use heat-sensitive materials like certain plastics, thin films, and even some specialized papers. This versatility allows for a wider product offering and the exploration of new label applications.

From an environmental perspective, LED UV curing offers significant advantages. The energy efficiency translates to a lower carbon footprint for the printing operation. The absence of mercury in LED lamps makes them a more environmentally friendly alternative to traditional UV systems. Furthermore, the instant curing process can reduce the need for VOC (Volatile Organic Compound) emitting solvents often found in conventional inks.

Optimizing Ink Formulations for LED UV

To fully harness the power of LED UV curing, ink formulations are critical. Manufacturers have developed specialized UV-curable inks specifically designed for LED curing. These inks contain photoinitiators that are highly sensitive to the specific wavelengths emitted by LED lamps (typically in the 365 nm, 385 nm, 395 nm, or 405 nm ranges).

Using the correct ink formulation ensures maximum curing efficiency, which directly impacts color vibrancy and ink durability. When these optimized inks are exposed to the targeted LED UV light, they cure faster and more completely, leading to superior print results. This synergy between LED technology and ink chemistry is key to achieving the desired outcomes in color fidelity and drying speed.

Conclusion: The Future is LED UV for Labels

Maximizing color fidelity and ink drying speed is no longer a trade-off. LED UV curing technology provides a powerful solution for the modern label printing industry. Its ability to deliver vibrant, accurate colors while enabling rapid, efficient drying makes it an indispensable tool. Whether in flexographic, offset, or narrow web printing, LED UV systems offer enhanced productivity, broader substrate compatibility, and a more sustainable printing process. As brands continue to push for higher quality and faster turnaround times, LED UV curing stands out as a technology that not only meets but exceeds expectations in label production.