I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Discover the key differences in maintenance and care between UV mercury lamps and UV LED curing systems in flexographic printing. Learn how to optimize your equipment’s performance and longevity with our comprehensive guide.

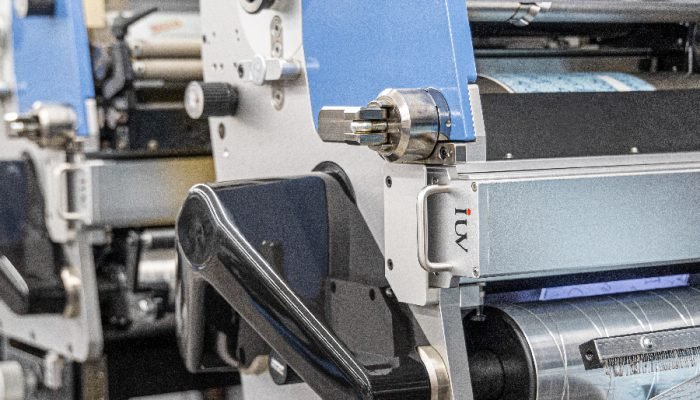

In the flexographic printing industry, UV curing systems play a crucial role in ensuring the quality and durability of printed materials.

Two primary types of UV curing systems are widely used: traditional UV mercury lamps and modern UV LED curing systems.

Each system has its unique characteristics, and understanding their maintenance and care requirements is essential for optimal performance and longevity.

This guide provides a detailed comparison of the maintenance and care procedures for both UV mercury lamps and UV LED curing systems, helping you make informed decisions and maximize the efficiency of your printing operations.

1. Daily Checks and Cleaning

- UV Mercury Lamps

Lamp Check:

Daily Inspection: Before starting the machine each day, inspect the lamp for any damage, cracks, or dirt. If any issues are found, replace the lamp immediately.

Regular Replacement: Record the lamp’s usage time and replace it every 1000 to 2000 hours, as recommended by the manufacturer.

Reflector Cleaning:

Regular Cleaning: Use a soft cloth and specialized cleaning agent to clean the reflector regularly. Ensure the surface is free from dust and debris. Avoid using hard objects that could scratch the reflector.

Cooling System:

Coolant Flow and Quality: Check the coolant flow and quality to ensure the cooling system is functioning properly. Replace the coolant periodically to prevent the buildup of scale and impurities.

Fan and Heat Sink: Inspect the cooling fan and heat sink for proper operation. Clean them to remove dust and debris, ensuring good ventilation.

- UV LED Curing Systems

LED Module Check:

Daily Inspection: Inspect the LED modules for any damage or abnormalities before starting the machine. Regularly check the working status of the LEDs to ensure they are all functioning correctly.

Usage Tracking: Record the usage time of the LED modules, which typically have a lifespan exceeding 20,000 hours. Regular checks are still necessary to ensure optimal performance.

Optical Component Cleaning:

Cleaning LED Modules: Regularly clean the LED modules to remove dust and oil, ensuring efficient light transmission. Use specialized cleaning agents and lint-free cloths.

Lens and Optics: Clean the lenses and other optical components to maintain high light transmission efficiency. Use specialized cleaning agents and lint-free cloths.

Cooling System:

Coolant Flow and Quality: Check the coolant flow and quality to ensure the cooling system is functioning properly. Replace the coolant periodically to prevent the buildup of scale and impurities.

Fan and Heat Sink: Inspect the cooling fan and heat sink for proper operation. Clean them to remove dust and debris, ensuring good ventilation.

2. Regular Maintenance

- UV Mercury Lamps

Lamp Replacement:

Usage Tracking: Record the lamp’s usage time and replace it every 1000 to 2000 hours, as recommended by the manufacturer.

Replacement Procedure: Turn off the power and wait for the lamp to cool down. Follow the manufacturer’s instructions to replace the lamp, ensuring it is installed correctly and securely.

Quartz Glass Cleaning:

Regular Cleaning: Regularly clean the quartz glass to remove dust and oil, ensuring efficient light transmission. Use specialized cleaning agents and lint-free cloths.

Lubrication of Moving Parts:

Lubrication Points: Lubricate all moving parts, such as rails and sliders, using the manufacturer-recommended lubricants. Follow the correct lubrication methods.

Regular Lubrication: Lubricate the moving parts according to the manufacturer’s recommendations to ensure smooth operation.

- UV LED Curing Systems

LED Module Inspection:

Regular Checks: Regularly inspect the LED modules for any faults and replace them if necessary. Record the usage time, although the lifespan is long, regular checks are still important.

Replacement Procedure: If an LED module needs replacement, turn off the power and wait for the device to cool down. Follow the manufacturer’s instructions to replace the module.

Optical Component Cleaning:

Regular Cleaning: Regularly clean the LED modules, lenses, and other optical components to ensure high light transmission efficiency. Use specialized cleaning agents and lint-free cloths.

Cleaning Frequency: Clean the optical components based on the cleanliness of the production environment. Regular cleaning ensures the components remain dust-free and efficient.

Electrical Connection Check:

Terminal Check: Inspect all electrical connections to ensure they are secure and free from corrosion. Tighten screws or replace terminals if necessary.

Grounding Check: Ensure the grounding of the UV LED curing system is in good condition to prevent static buildup and electric shock risks.

3. Fault Diagnosis and Emergency Handling

- UV Mercury Lamps

Lamp Not Lighting:

Power and Wiring Check: Check the power lines, connectors, and switches to ensure they are functioning correctly. If the lamp is damaged, replace it.

Replacement: If the lamp is faulty, follow the replacement procedure to install a new one.

Cooling System Failure:

Coolant Flow and Temperature Check: Check the coolant flow and temperature. Clear any blockages in the cooling system. If the issue persists, check the pump and heat sink for proper operation.

Blockage Removal: If blockages are found, clear them to ensure the coolant flows freely.

Control System Failure:

Indicator Lights and Alarms: Check the control panel for indicator lights and alarm messages. Refer to the user manual for initial diagnosis. If the issue cannot be resolved, contact technical support.

Fault Recording: Record the specific details of the fault to assist technicians in diagnosing and repairing the system.

- UV LED Curing Systems

LED Module Not Lighting:

Power and Wiring Check: Check the power lines, connectors, and switches to ensure they are functioning correctly. If the LED module is damaged, replace it.

Replacement: If the LED module is faulty, follow the replacement procedure to install a new one.

Cooling System Failure:

Coolant Flow and Temperature Check: Check the coolant flow and temperature. Clear any blockages in the cooling system. If the issue persists, check the pump and heat sink for proper operation.

Blockage Removal: If blockages are found, clear them to ensure the coolant flows freely.

Control System Failure:

Indicator Lights and Alarms: Check the control panel for indicator lights and alarm messages. Refer to the user manual for initial diagnosis. If the issue cannot be resolved, contact technical support.

Fault Recording: Record the specific details of the fault to assist technicians in diagnosing and repairing the system.

4. Maintenance Costs and Frequency

- UV Mercury Lamps

High Maintenance Costs: Frequent lamp and reflector replacements lead to higher maintenance costs.

Frequent Maintenance: The short lifespan of the lamps (1000 to 2000 hours) requires more frequent replacements and maintenance.

Spare Part Costs: The cost of spare parts, such as lamps and reflectors, is relatively high, increasing overall maintenance costs.

- UV LED Curing Systems

Low Maintenance Costs: The long lifespan of LED modules (typically over 20,000 hours) reduces the frequency of replacements and maintenance, leading to lower costs.

Less Frequent Maintenance: The long lifespan of LED modules means less frequent maintenance, reducing downtime and maintenance workload.

Spare Part Costs: The cost of spare parts, such as LED modules, is generally lower, further reducing overall maintenance costs.

5. Safety and Environmental Impact

- UV Mercury Lamps

Ozone Generation: Mercury lamps generate ozone during operation, requiring good ventilation to protect operator health.

High Operating Temperatures: High operating temperatures increase the risk of fire.

Lamp Breakage: Broken lamps can release harmful substances, necessitating special safety precautions.

Environmental Impact:

Mercury Content: Mercury lamps contain mercury, which requires special disposal procedures and can have environmental impacts.

Energy Efficiency: Mercury lamps have lower energy efficiency, resulting in higher energy consumption.

- UV LED Curing Systems

No Ozone Generation: LED lamps do not generate ozone, eliminating the need for special ventilation.

Low Operating Temperatures: Lower operating temperatures reduce the risk of fire.

No Harmful Substances: LED lamps do not contain mercury, and even if they break, they do not release harmful substances.

Environmental Impact:

No Mercury: LED lamps are mercury-free, making them more environmentally friendly. Disposal is simpler and safer.

Energy Efficiency: LED lamps have higher energy efficiency, resulting in lower energy consumption and reduced carbon footprint.

Understanding the maintenance and care requirements of UV mercury lamps and UV LED curing systems is essential for optimizing the performance and longevity of your flexographic printing equipment.