Flexible packaging demands speed, efficiency, and superior print quality. Traditionally, UV curing systems, particularly those used in narrow web printing, have relied on mercury vapor lamps. However, the advent of high-intensity LED curing technology presents a transformative opportunity for the flexible packaging sector. This advanced approach offers significant advantages in terms of energy efficiency, environmental impact, and print performance, making it a compelling choice for converters seeking to stay competitive.

The Evolution of UV Curing in Printing

For decades, UV curing has been a staple in the printing industry, offering near-instantaneous drying of inks and coatings. This rapid curing process allows for faster production speeds, enables the use of heavier ink laydowns, and provides excellent scuff and chemical resistance. In flexible packaging, where substrate versatility and demanding performance requirements are paramount, UV curing has played a vital role in achieving high-quality results across a variety of applications, from food wrappers to pharmaceutical pouches.

Limitations of Traditional UV Curing

While effective, traditional mercury vapor UV lamps come with certain drawbacks. They generate a considerable amount of heat, which can be problematic for heat-sensitive substrates commonly used in flexible packaging. This heat can lead to substrate deformation or degradation, limiting production speeds and the types of materials that can be used. Furthermore, mercury lamps have a finite lifespan and require regular replacement, contributing to ongoing operational costs and environmental concerns. Their energy consumption is also significantly higher compared to newer technologies.

The LED Curing Advantage

High-intensity LED curing systems represent a paradigm shift. Instead of a broad spectrum of UV light, LEDs emit a highly specific wavelength. This precise emission is not only more energy-efficient but also generates far less heat. For flexible packaging converters, this translates into several key benefits.

Firstly, the reduced heat output allows for the safe and effective curing of a wider range of flexible substrates, including thin films and heat-sensitive plastics, without compromising their integrity. This opens up new possibilities for material selection and product innovation.

Secondly, LEDs have an exceptionally long operational life, often exceeding 20,000 hours, drastically reducing maintenance and replacement costs associated with traditional mercury lamps. This longevity contributes to greater uptime and a more predictable operational budget.

Thirdly, the energy efficiency of LED curing is remarkable. They consume a fraction of the power required by mercury lamps, leading to substantial savings on electricity bills and a reduced carbon footprint. This is increasingly important as businesses globally focus on sustainability initiatives.

High-Intensity LEDs and Flexible Packaging Applications

The “high-intensity” aspect of these LED systems is crucial for flexible packaging. High intensity means more UV energy delivered to the ink or coating in a shorter amount of time. This is critical for achieving complete and rapid cure, especially with thicker ink layers or specialized coatings used in demanding flexible packaging applications.

In flexographic printing, a dominant process for narrow web flexible packaging, high-intensity LEDs can ensure excellent ink adhesion and cure speed, even on challenging substrates like polyolefins. This is vital for maintaining brand integrity and product protection throughout the supply chain. The precision of LED curing also contributes to sharper dot reproduction and better color consistency, enhancing the visual appeal of the final package.

For offset (or lithographic) printing on flexible materials, a process often used for specific types of packaging, LED curing ensures that inks and varnishes are fully cured immediately after printing. This prevents smudging and allows for immediate post-processing steps, streamlining the entire production workflow.

Addressing Specific Printing Processes

Narrow Web Flexography and LED Curing

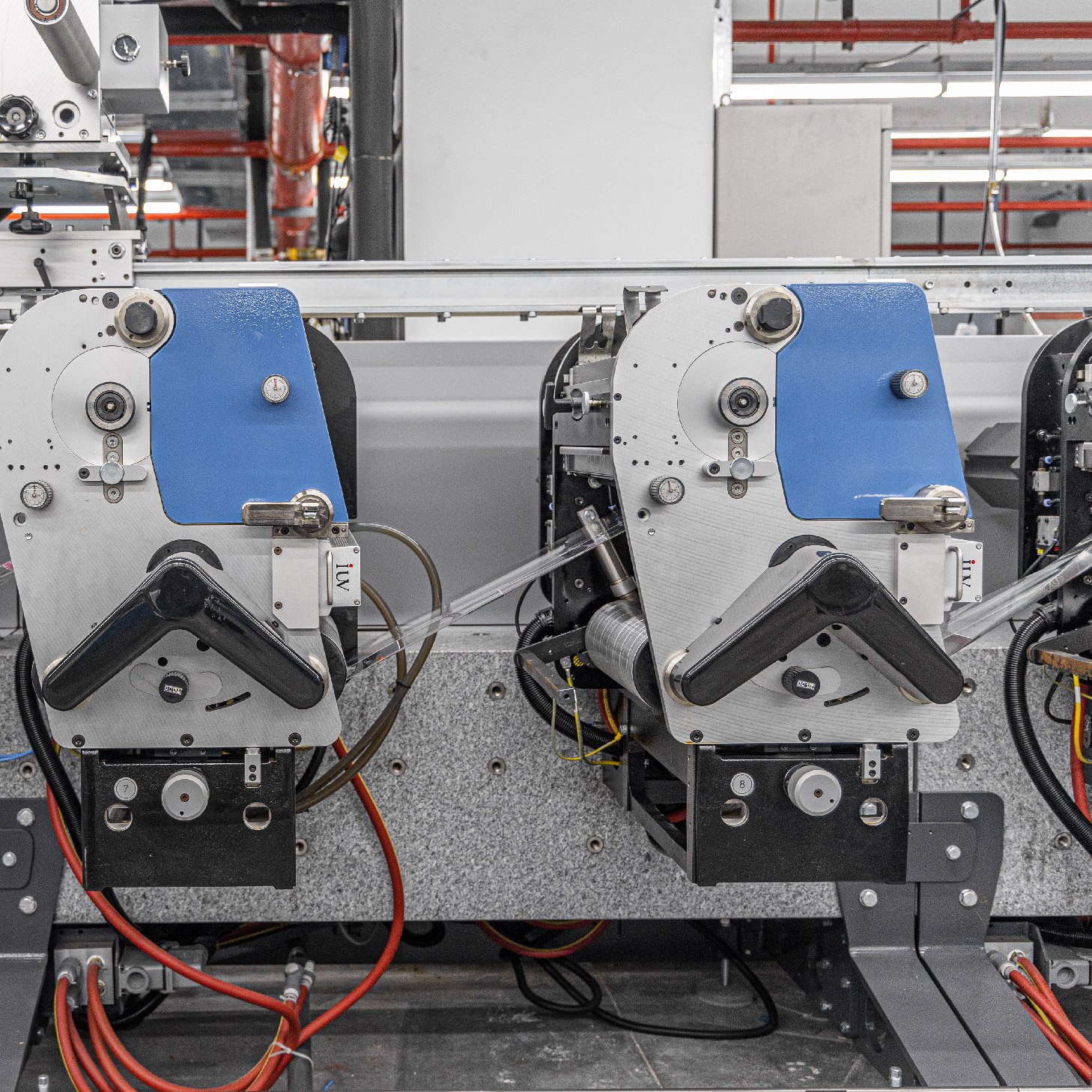

Narrow web flexography is a cornerstone of flexible packaging production. High-intensity LED curing is particularly well-suited for this application. The compact nature of LED curing units allows them to be easily integrated into existing flexo presses without significant modifications. The fast response time of LEDs means printers can achieve high production speeds while ensuring a complete cure on a variety of films, papers, and laminates. The reduced heat also minimizes the risk of web stretching or distortion, leading to more accurate registration and consistent print quality.

Narrow Web Offset and LED Curing

While flexography is widespread, narrow web offset printing also finds its place in flexible packaging. The benefits of LED curing are equally pronounced here. Offset inks, which can sometimes be slower to cure than UV flexo inks, benefit immensely from the targeted energy of high-intensity LEDs. This ensures that even dense ink coverage cures quickly and effectively, preventing issues like ink set-off and allowing for immediate handling and finishing.

Beyond Narrow Web: Potential for Wider Applications

While the focus is often on narrow web for flexible packaging, the principles of high-intensity LED curing are scalable. As the technology advances and becomes more powerful, its application in wider web flexible packaging presses will likely increase, offering the same benefits of energy savings, reduced heat, and superior curing performance to a broader range of converters.

Benefits Summarized for Flexible Packaging Converters

- Enhanced Substrate Compatibility: Cure a wider range of heat-sensitive films and papers without degradation.

- Improved Print Quality: Achieve sharper dots, better color consistency, and excellent adhesion.

- Increased Production Speeds: Near-instantaneous curing allows for faster press speeds and throughput.

- Significant Energy Savings: Drastically reduce power consumption and operational costs.

- Reduced Environmental Impact: Lower energy usage and elimination of mercury vapor lamp disposal.

- Lower Maintenance Costs: Long-life LEDs minimize downtime and replacement expenses.

- Immediate Handling and Finishing: Cured inks and coatings are ready for subsequent processes without delay.

- Consistent Performance: LEDs provide a stable light output over their lifespan, ensuring predictable curing results.

The Future of Flexible Packaging Curing

The integration of high-intensity LED curing technology into flexible packaging printing is not just an upgrade; it’s a strategic move towards greater efficiency, sustainability, and enhanced product quality. As demand for high-performance, visually appealing flexible packaging continues to grow, converters who adopt this advanced curing solution will be well-positioned to meet the challenges and seize the opportunities of the modern market. The precision, speed, and environmental advantages offered by high-intensity LED curing are setting a new standard for the industry.